Mechanical Design and Analysis in this comprehensive guide. These crucial engineering processes contribute to the development of safe, efficient, and innovative mechanical systems across various industries.Mechanical Design and Analysis are foundational aspects of engineering that play a critical role in developing machines, tools, and systems. They involve the conceptualization, creation, and refinement of mechanical components, ensuring they function efficiently, safely, and reliably. The essentials of mechanical design and analysis, helping you understand their importance and how they contribute to various industries.

Understanding Mechanical Design and Analysis

Mechanical Design and Analysis is the process of developing new mechanical systems or improving existing ones. It involves several stages, from the initial idea to the final product, each requiring meticulous attention to detail.

1. Conceptualization

The first step in Mechanical Design and Analysis is conceptualization. Engineers brainstorm ideas, considering the function and requirements of the system. This stage often involves sketching out rough designs and thinking about how the different parts will work together.

2. Detailed Design

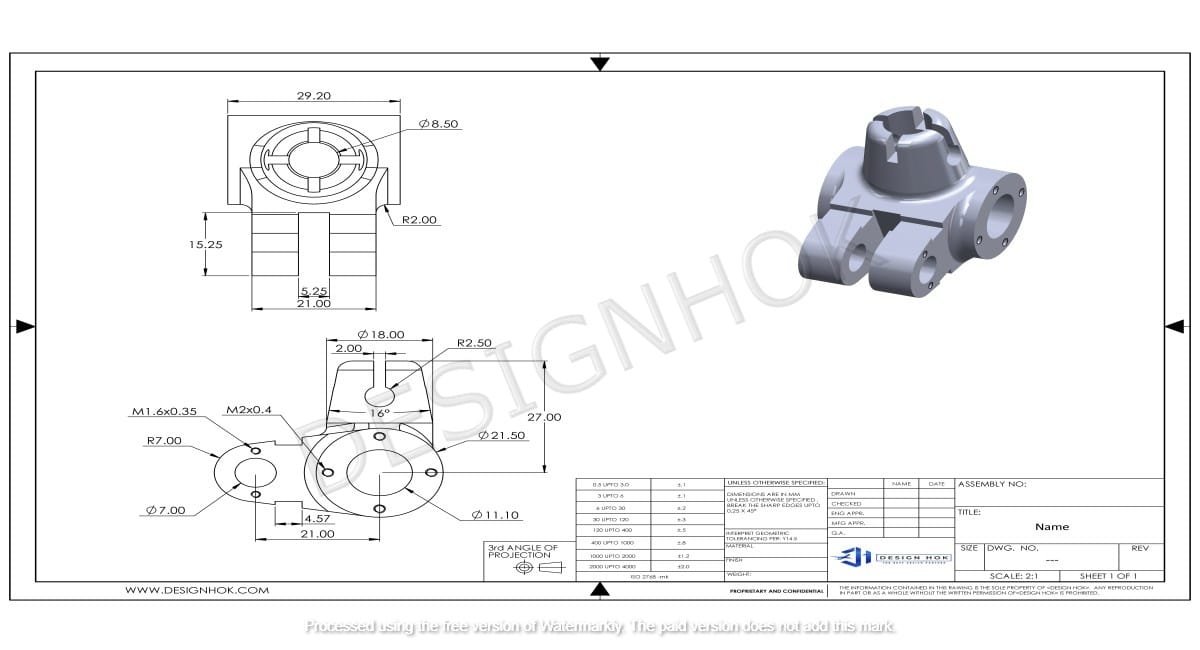

Once a concept is selected, the next step is detailed design. Engineers use Computer-Aided Design (CAD) software to create precise models of the system. This allows for accurate representation and helps in visualizing how the components will fit and interact.

3. Prototyping

After the design is finalized, a prototype is built. This physical model is used to test the design’s functionality and identify any potential issues. Prototyping is a crucial step, as it provides insights that can lead to further improvements.

4. Testing and Refinement

The prototype undergoes rigorous testing to ensure it meets all performance and safety standards. Based on the results, the design may be refined to address any shortcomings. This iterative process continues until the design is optimized.

What is Mechanical Design and Analysis?

Mechanical Design and Analysis is the evaluation of mechanical systems to ensure they can withstand the conditions they will encounter during operation. It involves various techniques to assess the strength, durability, and efficiency of the components.

1. Stress Analysis

Stress analysis determines how forces will affect the components of a mechanical system. Engineers analyze the stresses and strains that materials will undergo, ensuring they can handle the load without failing.

2. Thermal Analysis

Thermal analysis examines how temperature changes will impact the system. This is particularly important in systems where heat generation is significant, as excessive heat can lead to failure or reduced efficiency.

3. Vibration Analysis

Vibration analysis assesses how vibrations will affect the system. This is crucial in machines that operate under dynamic conditions, as vibrations can lead to fatigue and eventual failure if not properly managed.

4. Fatigue Analysis

Fatigue analysis evaluates how repeated loading cycles will affect the material over time. This helps predict the lifespan of the components and ensures they can endure the expected number of cycles without breaking.

Why Are Mechanical Design and Analysis Important?

Mechanical Design and Analysis are vital for several reasons:

- Safety: Proper design and analysis ensure that mechanical systems are safe to operate. By identifying and addressing potential failure points, engineers can prevent accidents and malfunctions.

- Efficiency: Optimized designs lead to more efficient systems, reducing energy consumption and operational costs. Mechanical analysis helps identify areas where improvements can be made to enhance performance.

- Innovation: Mechanical design drives innovation by enabling the development of new products and technologies. Through careful analysis, engineers can push the boundaries of what is possible.

- Reliability: Mechanical analysis ensures that systems are reliable and can perform consistently over time. This is essential for industries where downtime can lead to significant losses.

Applications of Mechanical Design and Analysis

Mechanical Design and Analysis are applied across a wide range of industries, including:

- Automotive: designing engines, transmissions, and other vehicle components.

- Aerospace: Developing aircraft structures, propulsion systems, and control mechanisms.

- Manufacturing: Creating machinery and tools for production processes.

- Robotics: Designing robots and automated systems for various applications.

- Consumer Products: Developing everyday items like appliances, gadgets, and tools.

Conclusion

Mechanical Design and Analysis are at the heart of engineering, enabling the creation of functional, efficient, and safe mechanical systems. By understanding the principles of design and the techniques used in analysis, engineers can develop innovative solutions that meet the demands of various industries. Whether it’s in automotive, aerospace, or consumer products, mechanical design and analysis ensure that the systems we rely on are robust, reliable, and ready to perform.

FAQs

1. What is the difference between mechanical design and analysis?

Mechanical design involves creating and developing mechanical systems, while mechanical analysis focuses on evaluating their performance under various conditions to ensure safety and reliability.

2. Why is prototyping important in mechanical design?

Prototyping allows engineers to test and validate their designs before mass production. It helps identify any issues and provides an opportunity to refine the design for better performance.

3. How does stress analysis contribute to mechanical design?

Stress analysis helps engineers understand how forces will impact the materials and components of a system. It ensures that the design can handle the expected loads without failing.

4. What industries benefit from mechanical design and analysis?

Industries such as automotive, aerospace, manufacturing, robotics, and consumer products all benefit from mechanical design and analysis, as these processes ensure the creation of efficient and reliable systems.

5. How do mechanical engineers use CAD software in design?

CAD software allows mechanical engineers to create detailed models of their designs, enabling precise visualization and analysis of how different components will fit and function together.