Transforming Concepts into Reality: The Power of Product Mechanical Design Services

Transforming Concepts into Reality: The Power of Product Mechanical Design ServicesTransforming Concepts into Reality: The Power of Product Mechanical Design Services

The Vital Role of Product Mechanical Design Services in Product Development

In today’s competitive market, the journey from a brilliant idea to a successful product is filled with challenges. One of the most crucial steps in this journey is mechanical design. Product mechanical design services are the backbone of creating a product that is not only functional but also efficient, reliable, and ready for the market. These services ensure that every component of a product is designed and tested to meet the highest standards. So, what makes mechanical design services so important, and what do they involve?

Product mechanical design services involve the detailed planning, modeling, and testing of the physical components of a product. These services help to ensure that the product will work as intended, can be manufactured efficiently, and will stand up to real-world use. Engineers who specialize in mechanical design work closely with developers to turn an idea into a product that is both practical and market-ready.

What Are Product Mechanical Design Services?

Product mechanical design services refer to a specialized area of engineering and design focused on developing and refining the mechanical aspects of a product. These services involve the creation, analysis, and optimization of mechanical systems and components to ensure that a product functions efficiently, reliably, and safely.

Here’s a breakdown of what product mechanical design services typically include:

-

Concept Development:

- This is the initial phase where ideas are generated and conceptualized. Designers and engineers work together to create rough sketches, models, and prototypes to explore different design possibilities and determine the best approach for the product.

-

Detailed Design:

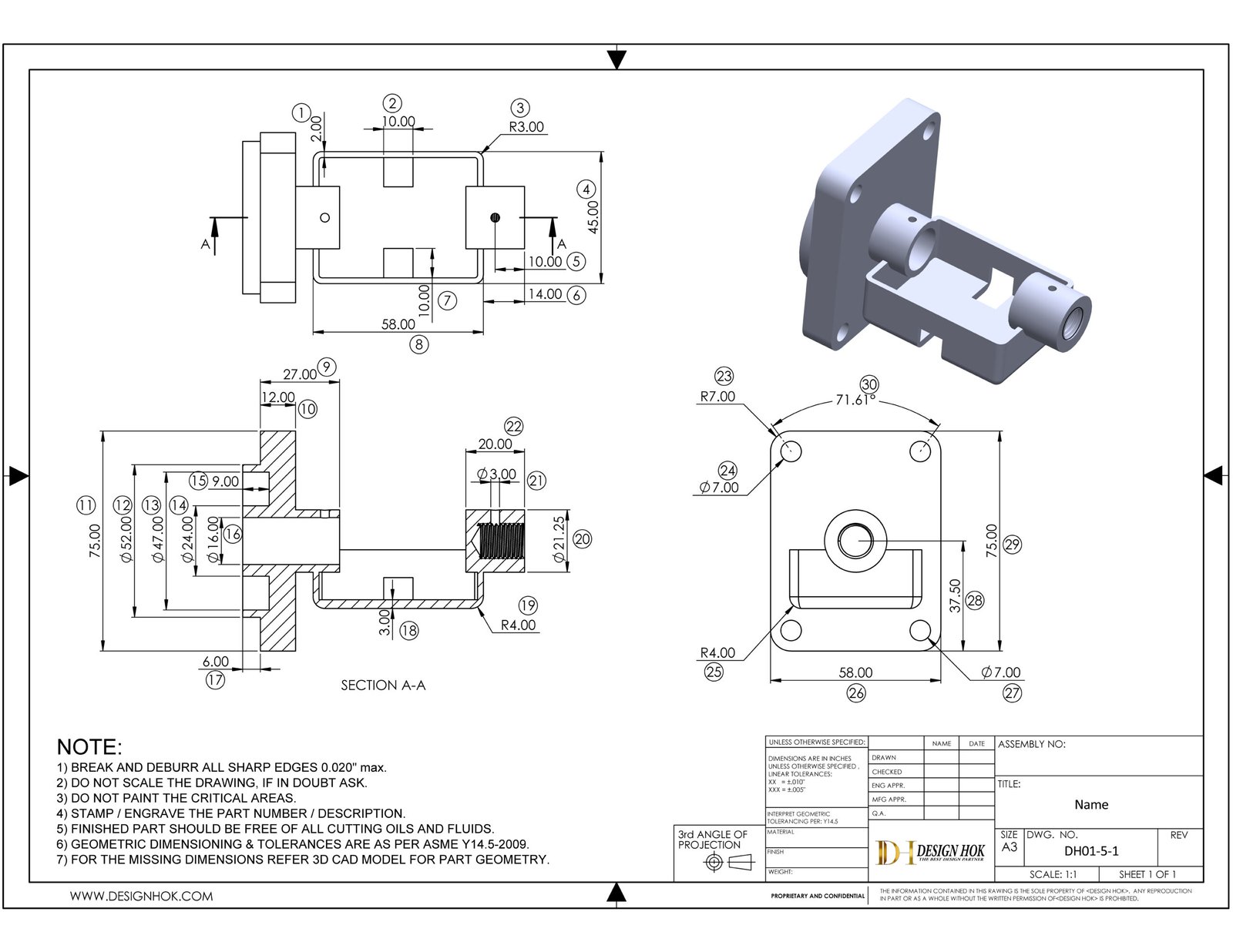

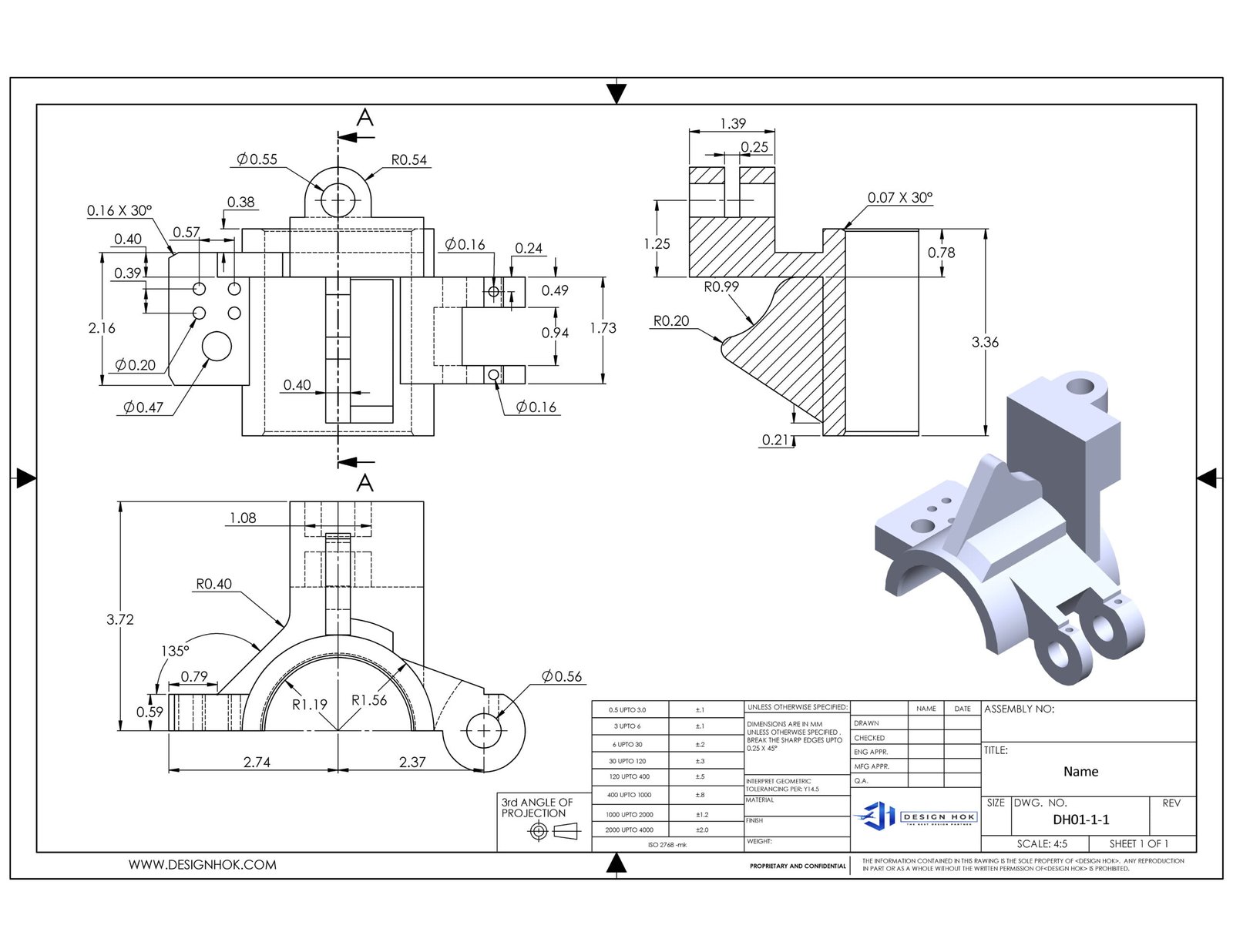

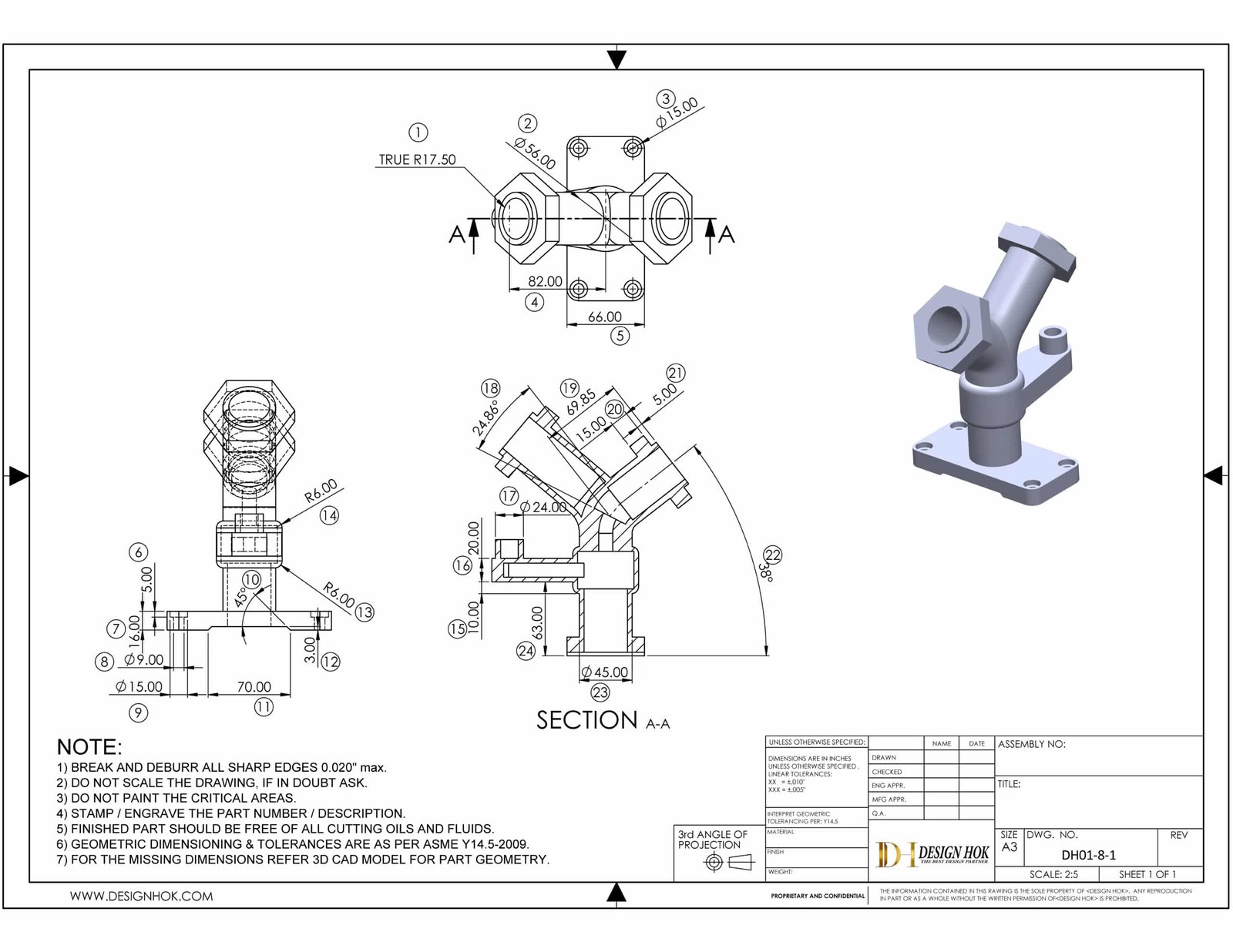

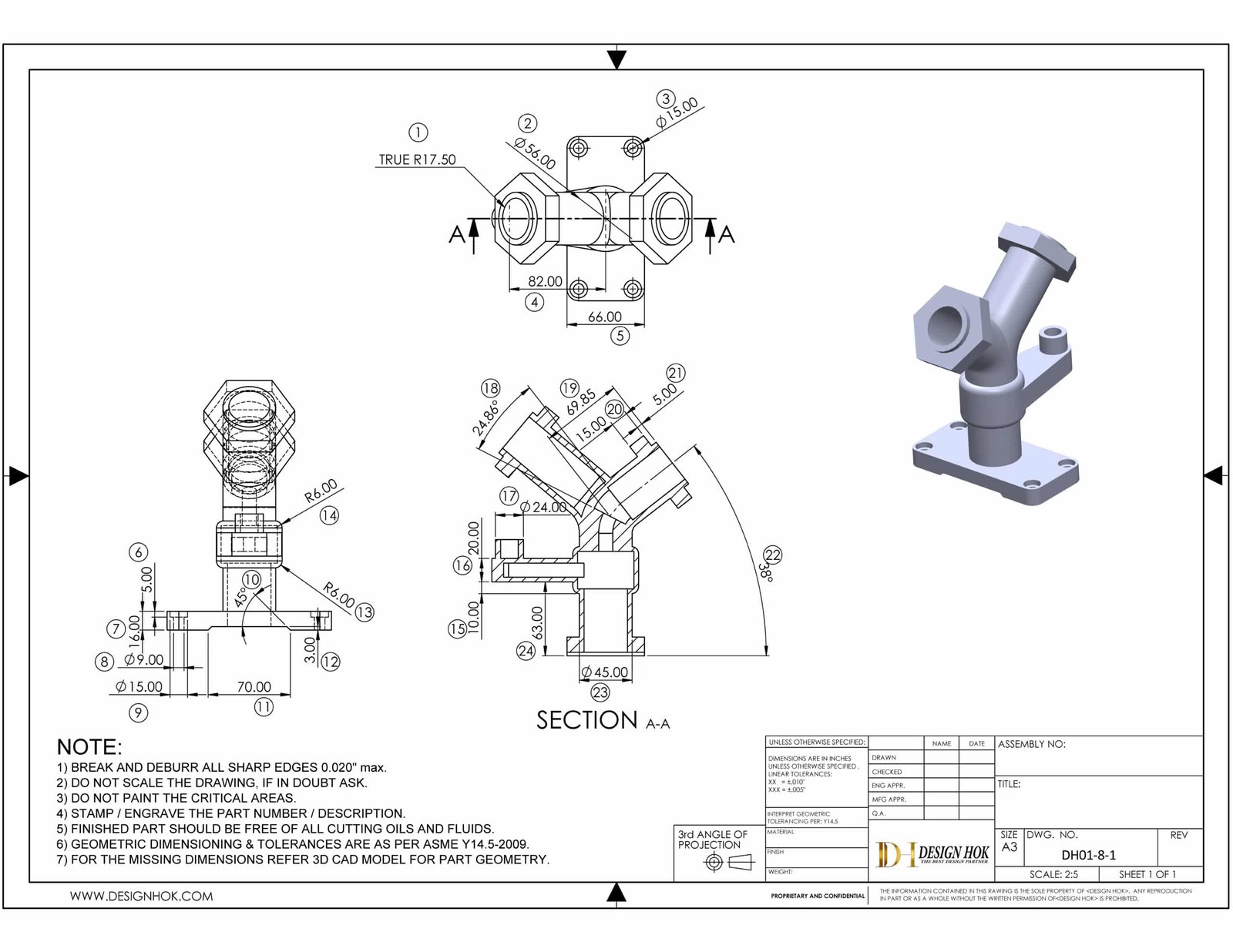

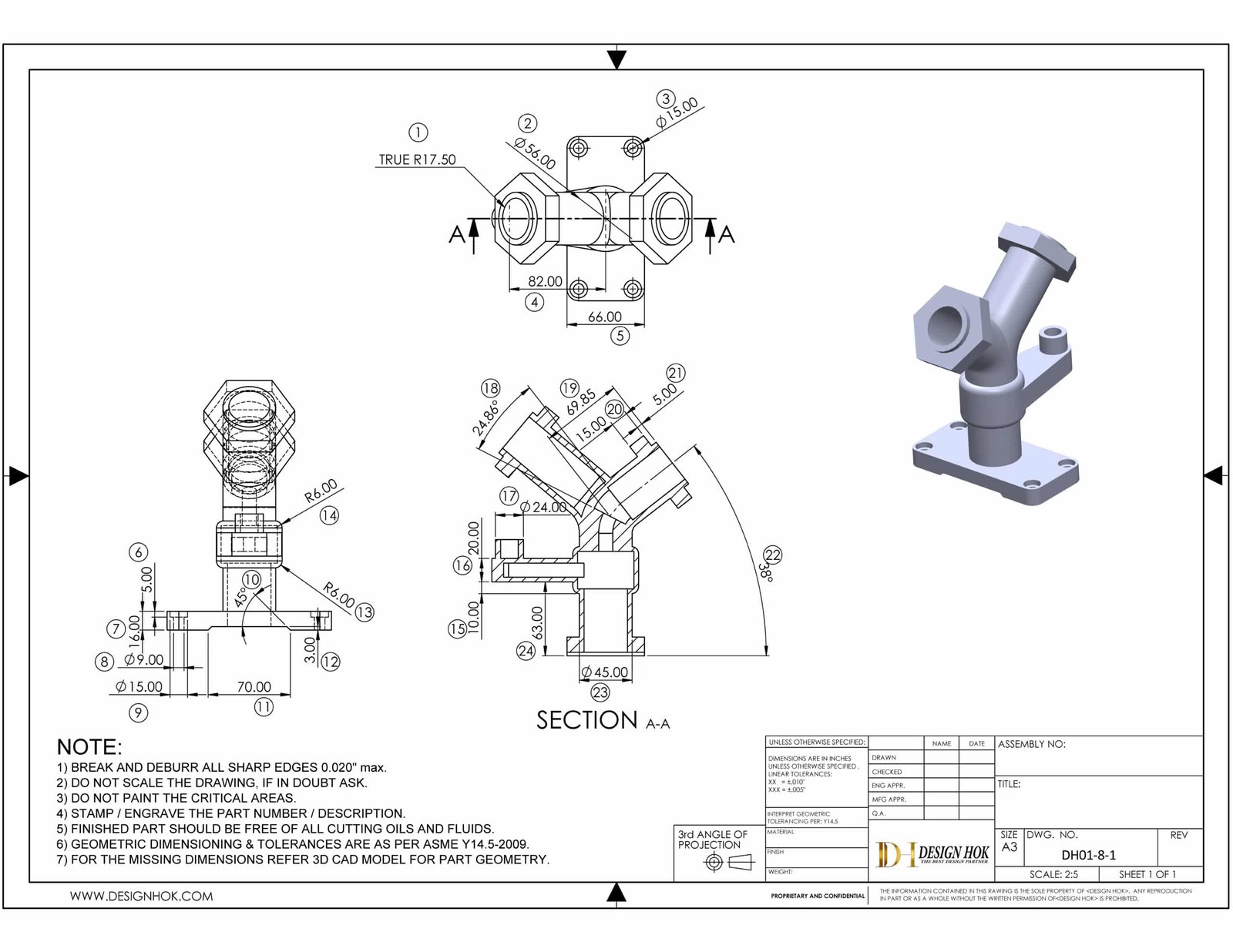

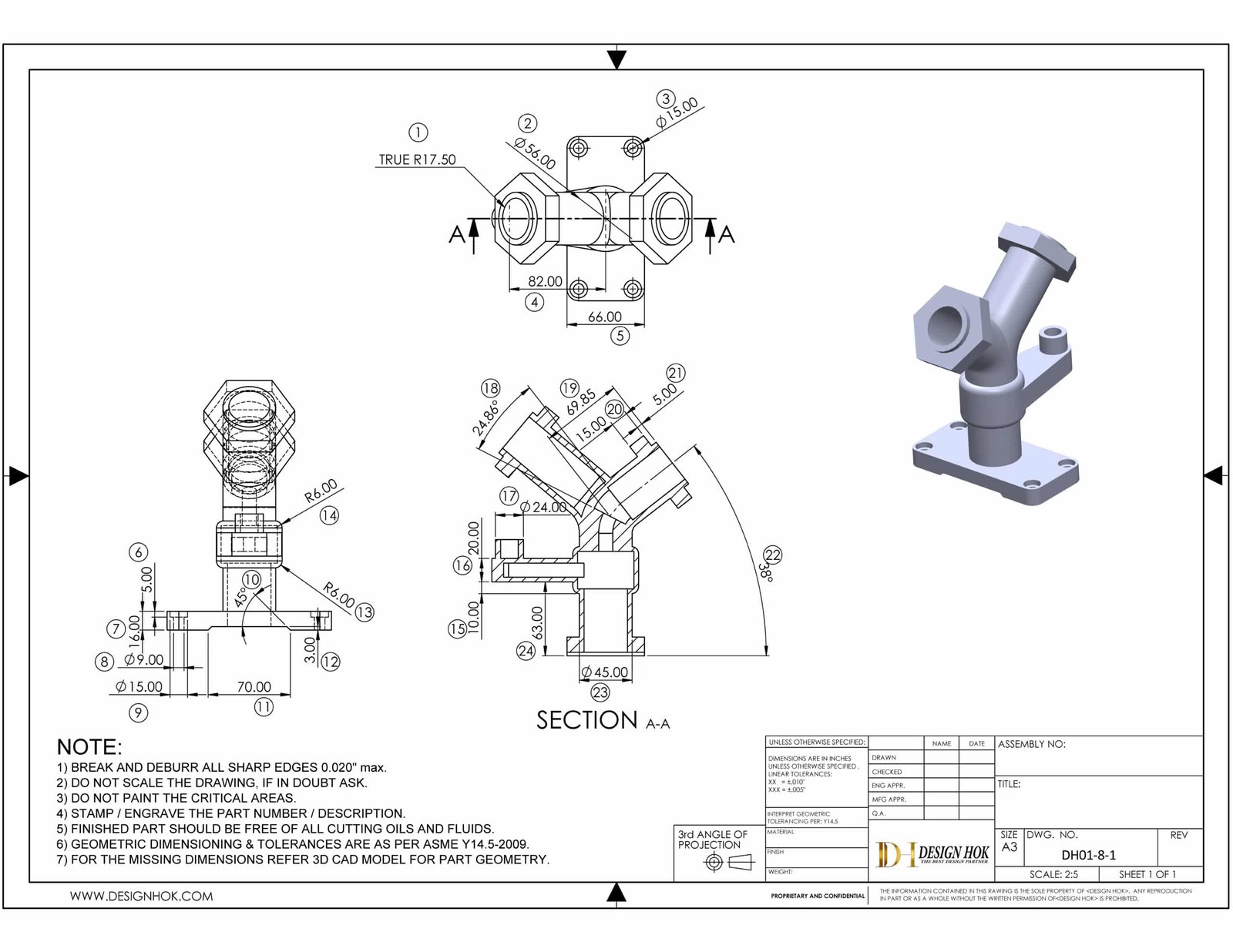

- In this phase, the concept is translated into a detailed design. This involves creating 3D models using CAD (Computer-Aided Design) software, defining the specifications for each component, and ensuring that all parts fit together properly.

-

Material Selection:

- Choosing the right materials is crucial for the product’s durability, cost, and performance. Mechanical design services include analyzing the material options and selecting those that best meet the product’s requirements.

-

Prototyping:

- Prototypes are created to test the design in real-world conditions. This allows for the identification and resolution of any issues before the product goes into mass production.

-

Testing and Validation:

- Mechanical design services often include rigorous testing to validate the design. This can involve stress testing, thermal analysis, and other simulations to ensure the product meets safety and performance standards.

-

Optimization:

- The design is refined to improve efficiency, reduce costs, and enhance performance. This might involve rethinking the design to use fewer materials, simplifying the assembly process, or improving the product’s ergonomics.

-

Manufacturing Support:

- Once the design is finalized, mechanical design services also include preparing the product for manufacturing. This involves creating detailed drawings, assembly instructions, and quality control guidelines to ensure the product can be produced consistently and to high standards.

-

Compliance and Standards:

- Ensuring the product meets industry standards and regulations is a critical part of mechanical design services. This includes adhering to safety, environmental, and industry-specific standards.

Product mechanical design services are essential for turning an idea into a functional, market-ready product. Whether developing a new product from scratch or improving an existing one, these services provide the technical expertise needed to bring a design to life.

Why Are Mechanical Design Services Essential?

1. Turning Ideas into Reality

The first step in product development is to turn an idea into something tangible. Mechanical design services begin with conceptualizing the product through detailed sketches and 3D models. These models provide a clear vision of what the product will look like and how it will function. Creating prototypes from these models allows designers to test the product early on, identifying and fixing any issues before full-scale production begins.

2. Optimizing for Manufacturing

Designing a product isn’t just about how it will look or work—it’s also about how it will be made. Mechanical design services focus on making the product easy to manufacture. This means selecting the right materials, designing parts that fit together easily, and ensuring that the manufacturing process is cost-effective. By optimizing the design for manufacturing, companies can reduce waste, lower production costs, and speed up the time it takes to bring a product to market.

3. Ensuring Product Performance

For a product to be successful, it needs to perform reliably in the real world. Mechanical design services include rigorous testing and analysis to ensure that the product can withstand various stresses and conditions. Engineers simulate how the product will behave under different loads, temperatures, and environments. This testing helps to ensure that the final product is durable, reliable, and capable of meeting customer expectations.

4. Meeting Industry Standards

Every industry has specific standards and regulations that products must meet. Whether it’s safety standards, environmental regulations, or quality certifications, mechanical design services ensure that a product complies with all relevant requirements. Meeting these standards is not just about avoiding legal issues—it also helps build trust with customers and sets the product apart from the competition.

5. Reducing Costs and Time to Market

Efficiency is key in today’s fast-paced market. By optimizing the design for manufacturing and reducing the need for costly revisions, mechanical design services can significantly cut down on production costs and time to market. This allows companies to stay competitive and respond quickly to market demands.

The Long-Term Benefits of Mechanical Design

Investing in quality mechanical design services can have long-term benefits for a company. A well-designed product not only performs better but also tends to have a longer lifespan and fewer issues over time. This can lead to higher customer satisfaction, lower return rates, and a stronger reputation for quality. Additionally, a product that is easy and cost-effective to manufacture can lead to higher profit margins and a more successful business overall.

Conclusion

Product mechanical design services are an essential part of the product development process. They help ensure that a product is not only functional and reliable but also cost-effective and ready for the market. By turning ideas into reality, optimizing manufacturing, ensuring performance, and meeting industry standards, mechanical design services play a vital role in the success of any product.

For companies looking to bring a new product to market, investing in professional mechanical design services is a smart decision that can pay off in the long run.

FAQs

1. What are product mechanical design services?

Product mechanical design services involve the creation, development, and optimization of the mechanical aspects of a product. These services include everything from concept development and detailed design to material selection, prototyping, testing, and manufacturing support.

2. Why are mechanical design services important?

Mechanical design services are crucial for ensuring that a product functions correctly, is safe to use, and meets industry standards. They help turn a concept into a viable product that can be manufactured efficiently and cost-effectively.

3. What types of products require mechanical design services?

Any product with mechanical components can benefit from mechanical design services. This includes consumer electronics, automotive parts, industrial machinery, medical devices, household appliances, and more.

4. How do you select materials for a mechanical design?

Material selection is based on the product’s requirements, including strength, durability, weight, cost, and environmental factors. Engineers analyze different material options to choose the one that best suits the product’s needs.

5. What is the role of CAD software in mechanical design?

CAD (Computer-Aided Design) software is used to create detailed 3D models of the product. It allows designers to visualize the product, simulate how it will work, and make adjustments before creating physical prototypes.

6. How does prototyping fit into the mechanical design process?

Prototyping is an essential step in the design process that allows engineers to test the product in real-world conditions. It helps identify any flaws or areas for improvement before the product goes into full production.

7. What is the difference between a prototype and a final product?

A prototype is an early model used to test and refine the design. The final product is the fully developed, market-ready version that has passed all testing and validation stages.

8. How are mechanical designs optimized for cost and performance?

Design optimization involves refining the product to improve its performance, reduce manufacturing costs, and enhance its overall efficiency. This might include simplifying the design, using less expensive materials, or improving the manufacturing process.

9. What kind of testing is involved in mechanical design?

Mechanical design testing can include stress analysis, thermal analysis, vibration testing, and more. These tests ensure the product can withstand real-world conditions and meets all safety and performance standards.

10. How do mechanical design services support manufacturing?

Mechanical design services prepare the product for manufacturing by creating detailed drawings, assembly instructions, and quality control guidelines. This ensures the product can be produced consistently and to high standards.