Description:

Explore how The Role of 3D Modeling in Prototyping plays a vital role in the prototyping process, from concept visualization to manufacturing-ready designs. Discover how this powerful tool accelerates innovation, improves accuracy, and reduces development costs.

Introduction

The Role of 3D Modeling in Prototyping is a fundamental stage in product development where ideas begin to take physical form. Whether you’re developing a new gadget, a mechanical component, or a medical device, the prototype is your first real-world glimpse of how the final product might look and function. At the heart of this process lies 3D modeling—a technology that has revolutionized the way engineers, designers, and inventors approach design and development.

In the digital age, The Role of 3D Modeling in Prototyping is no longer a luxury—it is a necessity. It allows innovators to visualize, simulate, and refine their ideas before committing to the costly and time-consuming process of physical prototyping. In this blog, we will explore The Role of 3D Modeling in Prototyping and why it has become an indispensable tool for industries across the board.

What is The Role of 3D Modeling in Prototyping?

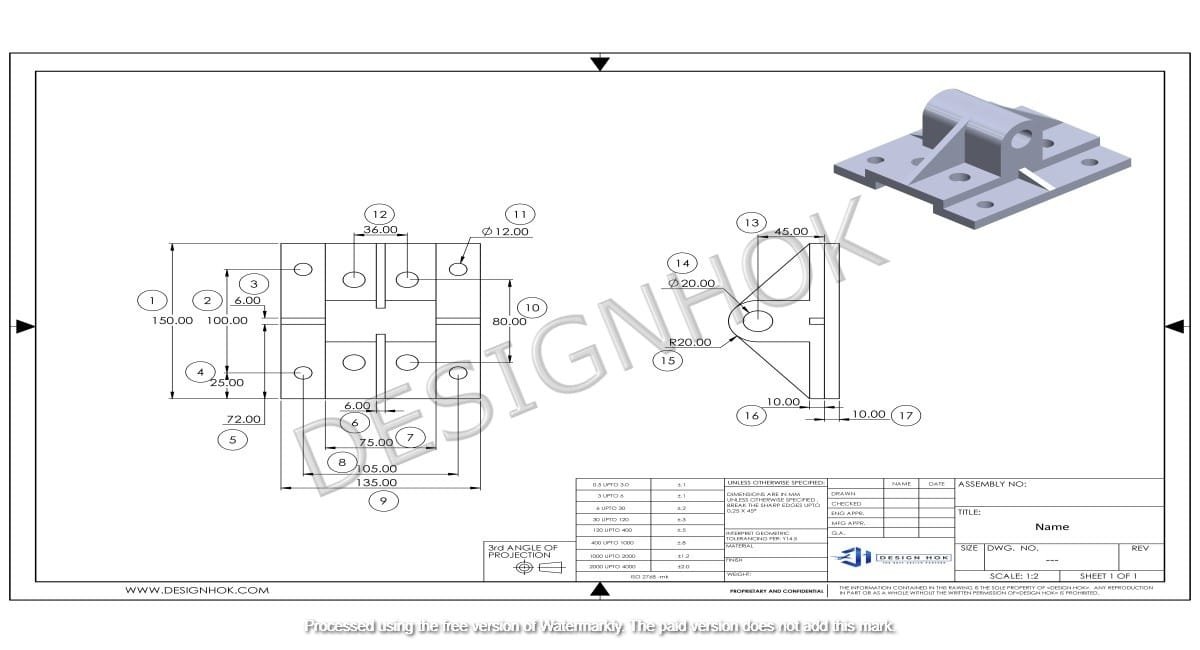

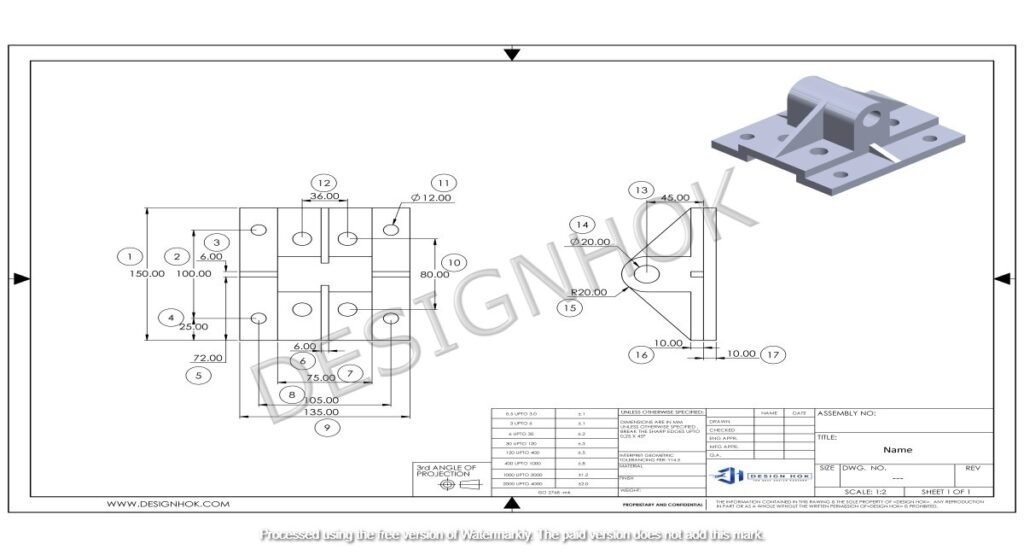

The Role of 3D Modeling in Prototyping is the process of creating a three-dimensional representation of an object using specialized software. These digital models include every detail of the object, including dimensions, geometry, textures, and sometimes even material properties. Common tools used for 3D modeling include Blender, AutoCAD, SolidWorks, Fusion 360, and SketchUp.

Unlike traditional 2D drawings, 3D models offer a realistic and interactive perspective of a design. They can be rotated, viewed from any angle, and even simulated under various conditions—all before anything is built.

The Evolution of Prototyping

Traditionally, prototyping was done manually using materials like wood, clay, or metal. This approach was often slow, expensive, and lacked the precision needed for complex products. With the introduction of Computer-Aided Design (CAD) and 3D modeling, the game changed dramatically.

Now, a designer can build a digital model, simulate how it behaves, make changes, and even 3D print a physical version within hours. This rapid shift has cut down the time and cost of prototyping while enhancing the overall quality and performance of end products.

Key Roles of 3D Modeling in Prototyping

Let’s look at The Role of 3D Modeling in Prototyping plays throughout the prototyping process:

1. Concept Visualization

Before any physical object is created, designers need to visualize the idea. 3D modeling helps translate ideas into visual formats, making it easier to:

- Understand how a product will look.

- Share concepts with teams or clients.

- Identify potential design flaws early.

This visual communication is particularly helpful for non-technical stakeholders who may struggle to understand complex 2D drawings.

2. Design Refinement

Prototyping is all about iteration. With 3D models, it becomes much easier to tweak designs without starting from scratch. You can:

- Adjust dimensions.

- Add or remove features.

- Improve ergonomics or performance.

The Role of 3D Modeling in Prototyping software provides version control, so changes can be tracked and compared. This flexibility is vital for teams working under tight deadlines and budgets.

3. Simulation and Analysis

Before a prototype is physically built, it can be tested virtually through simulations. Many 3D modeling platforms allow for:

- Stress and strain analysis.

- Heat distribution checks.

- Fluid flow simulation.

- Motion and assembly tests.

This ability to simulate real-world scenarios helps reduce risks and optimize functionality. It ensures that the physical prototype will perform as expected, which is especially important in aerospace, automotive, and medical industries.

4. Precision and Accuracy

Manual sketches and early-stage models often introduce human error. 3D modeling offers mathematical precision to ensure:

- Every measurement is accurate.

- Parts fit perfectly in assemblies.

- Manufacturing tolerances are met.

This level of detail is crucial when creating components that must interface with others or adhere to strict industry standards.

5. Rapid Prototyping and 3D Printing

One of the biggest advantages of The Role of 3D Modeling in Prototyping is its integration with additive manufacturing (3D printing). Once a digital model is complete, it can be sent directly to a 3D printer. This allows:

- Fast production of physical prototypes.

- On-the-fly changes without retooling.

- Low-cost single-unit fabrication.

Designers can quickly evaluate the physical model, make necessary adjustments, and print a new version—all within a day or two.

6. Cost Efficiency

Mistakes in prototyping can be costly. With 3D modeling:

- Errors are caught early.

- Material waste is reduced.

- Fewer physical iterations are needed.

This ultimately saves time and money. Businesses can also avoid investing in expensive tooling or molds until the design is finalized.

7. Enhanced Collaboration

3D models are easy to share and review. Teams across departments or continents can collaborate in real time. Features such as annotations, layer control, and interactive walkthroughs allow:

- Designers and engineers to stay aligned.

- Clients to give informed feedback.

- Manufacturers to understand exact requirements.

This collaborative approach minimizes miscommunication and leads to better outcomes.

8. Documentation and Manufacturing Readiness

Once the design is approved, 3D models can be used to generate:

- Assembly instructions.

- Part lists (BOM).

- Tool paths for CNC machines.

- Technical drawings.

This smooth handoff from design to production helps streamline the manufacturing process and reduces errors on the shop floor.

Real-World Applications

Industries where The Role of 3D Modeling in Prototyping enhances prototyping include:

- Consumer Electronics: Rapid iterations for ergonomic testing.

- Automotive: Wind tunnel simulations and crash testing.

- Medical Devices: Custom prosthetics and surgical tools.

- Aerospace: Lightweight component analysis.

- Architecture: Structural analysis and design visualization.

At DesignHok, 3D modeling is a core part of the design process, enabling clients to bring their ideas to life faster, more accurately, and with fewer resources.

Conclusion

The Role of 3D Modeling in Prototyping cannot be overstated. It brings together the power of visualization, accuracy, simulation, and production readiness into one seamless workflow. By allowing rapid iteration and reducing the risks associated with physical development, it empowers designers and engineers to innovate with confidence.

For companies like DesignHok, integrating The Role of 3D Modeling in Prototyping into the prototyping process has become a standard for delivering quality, speed, and client satisfaction. As technologies continue to evolve, the future of prototyping will be increasingly digital—and 3D modeling will remain at the center of that transformation.

FAQs: The Role of 3D Modeling in Prototyping

Q1: What software is commonly used for 3D modeling in prototyping?

Common tools include SolidWorks, Fusion 360, AutoCAD, Blender, Rhino, and SketchUp. Each has unique strengths depending on the industry and complexity of the model.

Q2: Is 3D modeling only useful for industrial products?

No. 3D modeling is used in various fields such as fashion, art, gaming, architecture, and medical design. It supports any application that benefits from a digital representation of an object.

Q3: Can I use 3D modeling for low-volume production?

Yes. With technologies like 3D printing and CNC machining, you can use 3D models to produce functional prototypes or even limited production runs.

Q4: Is it necessary to learn 3D modeling for prototyping?

While not mandatory, having basic knowledge helps in communicating with designers and engineers. Many companies offer services where skilled modelers handle the technical part for you.

Q5: How accurate are 3D printed prototypes based on 3D models?

Extremely accurate, depending on the printer’s resolution and material. Some 3D printers can achieve tolerances of ±0.1 mm, making them suitable for precise prototypes.