In the competitive world of industrial design, efficient and robust plant mechanical design is essential to drive performance and productivity. The role of plant mechanical design services in enhancing industrial operations, providing cost-effective and custom-built solutions, and ensuring sustainable practices.

Introduction

Plant mechanical design services are at the heart of industrial innovation, focusing on the efficient layout, structure, and function of critical mechanical components within production facilities. From pipelines to machinery, plant mechanical design covers a range of specialized services aimed at optimizing the operations of complex systems. This process involves rigorous planning, precision engineering, and thorough understanding of industry needs, making it indispensable for manufacturing, processing, and production industries worldwide. This article delves into the core aspects of plant mechanical design, its benefits, and the role it plays in driving productivity and sustainability within industries.

What are Plant Mechanical Design Services?

Plant mechanical design services are professional services that focus on creating, developing, and optimizing mechanical components within industrial plants. These services address the mechanical aspects of plant infrastructure, covering elements like heating, ventilation, piping systems, material handling, and mechanical layout planning. By providing comprehensive design strategies, they ensure that all mechanical systems within a plant are efficiently aligned with operational needs and safety standards.

Key Components of Plant Mechanical Design

- Piping Systems

Designing efficient piping systems is critical for industries such as oil and gas, chemical processing, and manufacturing. A well-designed piping system reduces energy consumption, prevents leaks, and ensures consistent flow rates. - Material Handling

This involves designing conveyor belts, elevators, and other systems that move materials within the plant. Proper material handling systems reduce downtime and enhance overall productivity. - Heating, Ventilation, and Air Conditioning (HVAC)

HVAC systems in industrial plants are essential for maintaining temperature and air quality, which can impact both the workforce and product quality. Well-designed HVAC systems improve energy efficiency and reduce operational costs. - Structural Support Systems

Structural systems in plant mechanical design provide the backbone for various machinery and components. This includes designing support beams, racks, and other structures that ensure equipment stability and safety. - Maintenance and Safety Protocols

Maintenance planning and safety considerations are built into plant mechanical design services to ensure that machinery operates smoothly and safely, minimizing potential hazards and costly breakdowns.

Benefits of Plant Mechanical Design Services

Plant mechanical design services bring numerous benefits that directly impact plant operations, product quality, and profitability:

- Enhanced Operational Efficiency

Efficient design improves the workflow within a plant, streamlining processes and reducing delays. This leads to smoother operations and reduces resource wastage. - Cost Efficiency

Well-planned mechanical designs lead to reduced operational and maintenance costs. By minimizing equipment wear and tear, plants save on frequent repairs and replacements. - Environmental Sustainability

Many plant mechanical design services now include sustainable practices that reduce the plant’s environmental footprint, such as energy-efficient systems and waste minimization strategies. - Safety Compliance

By adhering to stringent industry standards, plant mechanical designs contribute to a safer work environment. This not only prevents accidents but also ensures compliance with regulations, avoiding costly fines and liabilities. - Customization

Each plant has unique requirements, and custom-designed mechanical services tailor solutions that align precisely with the operational needs of the facility. Customization can include specialized piping layouts, unique HVAC setups, or tailored material handling systems.

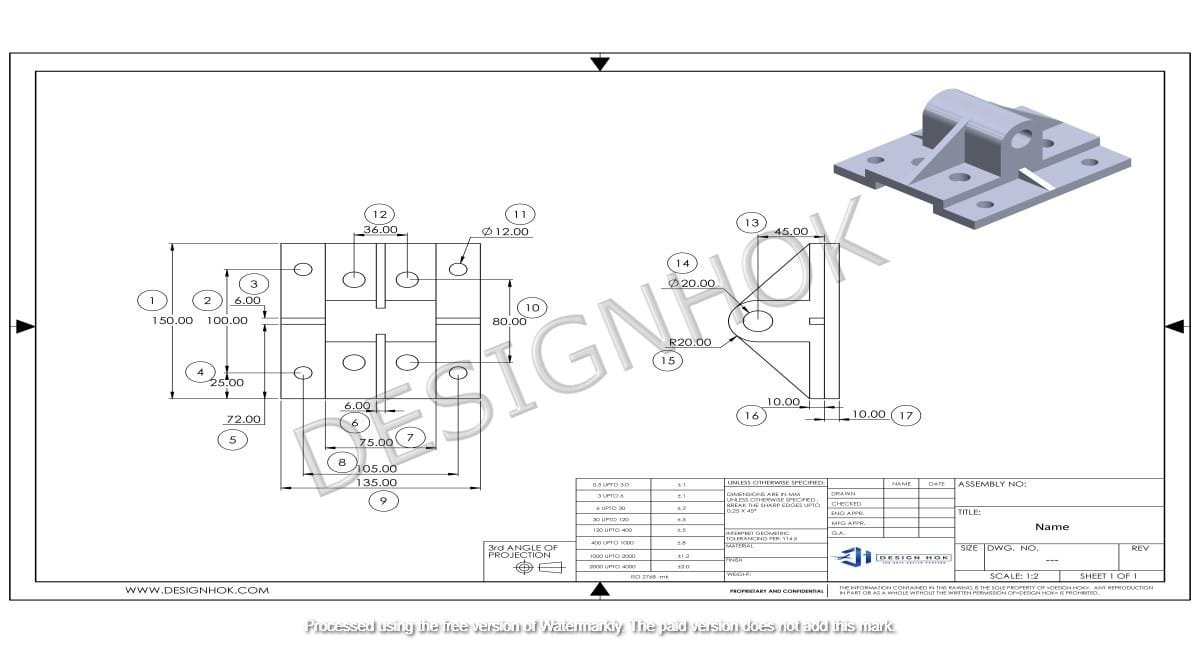

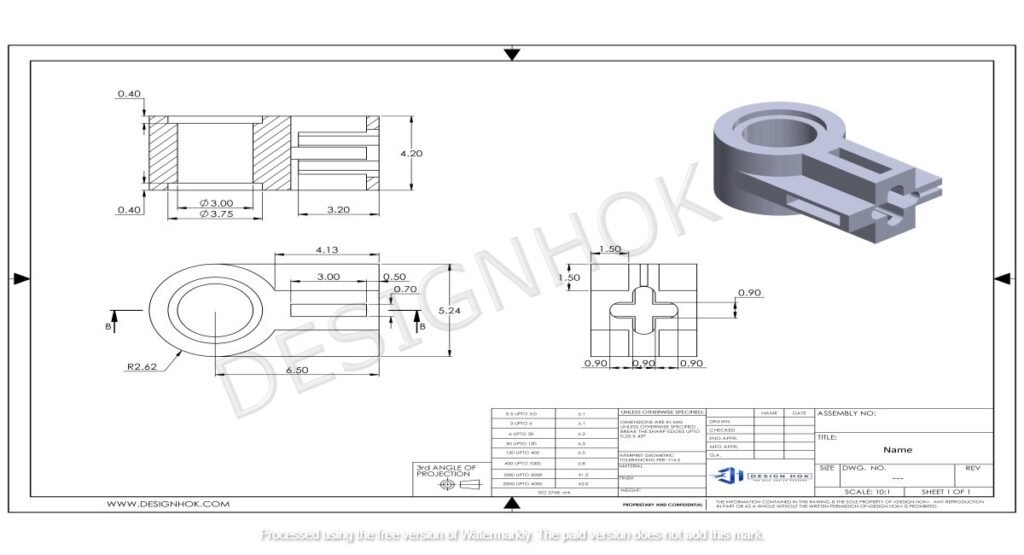

The Role of Technology in Plant Mechanical Design

With advancements in technology, plant mechanical design services are becoming more sophisticated and efficient. Computer-Aided Design (CAD) software allows engineers to visualize and test designs digitally, reducing potential errors and ensuring accuracy. In addition, Building Information Modeling (BIM) enables collaboration among different engineering teams, making the design process seamless and coordinated.

Choosing the Right Plant Mechanical Design Services Provider

Selecting the right provider for plant mechanical design services is crucial for successful project implementation. Key factors to consider include:

- Experience and Expertise

Choose providers with a proven track record in handling complex projects within your industry. - Technology and Resources

Opt for providers that use advanced tools, such as CAD and BIM, to offer precise and reliable design solutions. - Commitment to Sustainability

Sustainability is a growing priority; choose a provider committed to integrating environmentally responsible practices into their designs. - Customer Support

Post-implementation support is essential for the smooth operation of plant systems. Providers should offer robust support services for maintenance and troubleshooting.

Conclusion

Plant mechanical design services are fundamental to the success of industrial facilities, impacting everything from cost savings to operational efficiency and safety. With a carefully designed mechanical framework, plants can achieve higher productivity and meet their long-term goals more effectively. By choosing the right plant mechanical design services, industries can secure tailored solutions that meet both current and future demands, ultimately boosting profitability and sustainability.

FAQ

Q1: What industries benefit most from plant mechanical design services?

A: Industries such as oil and gas, manufacturing, chemical processing, food production, and pharmaceuticals benefit significantly. These sectors rely on efficient mechanical systems for productivity and safety.

Q2: How does plant mechanical design contribute to energy efficiency?

A: By optimizing systems such as HVAC, piping, and material handling, plant mechanical design reduces energy consumption, minimizing costs and environmental impact.

Q3: Are plant mechanical design services customizable?

A: Yes, these services are highly customizable to meet the unique needs of each facility, including tailored piping layouts, HVAC systems, and material handling solutions.

Q4: What role does technology play in modern plant mechanical design?

A: Technologies like CAD and BIM are used to improve precision, enhance collaboration, and reduce errors during the design process, making it more efficient and reliable.

Q5: What should I look for in a plant mechanical design service provider?

A: Look for providers with relevant experience, advanced technological resources, a focus on sustainability, and strong post-implementation support for optimal results.