Description:

Mechanics-based design forms the cornerstone of engineering, providing the scientific framework to create structures and machines that are efficient, durable, and safe. This approach integrates principles of mechanics with innovative technologies, ensuring the optimal performance of both static structures and dynamic machines.

Introduction

The mechanics-based design is a specialized engineering discipline that combines theoretical mechanics, material science, and advanced computational tools. By analyzing forces, stresses, and motions, engineers can predict how structures and machines will perform under real-world conditions. Whether designing skyscrapers to withstand earthquakes or machines to function seamlessly in industrial settings, mechanics-based design ensures precision, safety, and sustainability.

Core Principles of Mechanics-Based Design

1. Statics and Dynamics

Mechanics-based design hinges on the understanding of statics (forces in equilibrium) and dynamics (forces in motion). For structures, statics ensures stability by evaluating loads, reactions, and supports. In contrast, dynamics applies to machines, analyzing motion, velocity, and acceleration to optimize efficiency.

2. Stress and Strain Analysis

Stress and strain analysis evaluates how materials deform under forces. Structures and machines face various stresses—tension, compression, shear, and torsion. A mechanics-based approach ensures that these components remain within safe limits to prevent failure.

3. Material Behavior

Material selection plays a critical role. Mechanics-based design incorporates material properties like elasticity, ductility, and fatigue resistance. Engineers choose materials based on their behavior under specific environmental and operational conditions.

4. Energy Methods

Energy principles such as work-energy and potential energy help in the design of efficient machines and resilient structures. These methods ensure minimal energy wastage, contributing to sustainability and cost-effectiveness.

Applications of Mechanics-Based Design

1. Structural Engineering

- Skyscrapers and Bridges: Mechanics principles help design tall buildings and long-span bridges that can withstand wind, seismic forces, and heavy traffic loads.

- Industrial Facilities: Factories and warehouses require structures that can support machinery, resist vibrations, and ensure safety.

2. Machine Design

- Robotics: Mechanics aids in creating robotic arms, joints, and grippers that operate smoothly with precise motion control.

- Manufacturing Equipment: Machines like conveyors, presses, and cutters rely on mechanics for durability and accuracy.

3. Aerospace and Automotive Engineering

- Aircraft Components: Mechanics ensures the structural integrity of wings, fuselages, and landing gear.

- Vehicles: Cars and trucks benefit from mechanics-based design in chassis construction, suspension systems, and crash safety features.

4. Energy Systems

- Wind Turbines: Structural mechanics optimize the blades and towers to withstand varying wind conditions.

- Hydropower Systems: Mechanics ensures efficient design of turbines and dams.

Tools and Technologies in Mechanics-Based Design

1. Finite Element Analysis (FEA)

FEA simulates stresses and deformations in complex structures and machines, providing visual and quantitative insights into their performance.

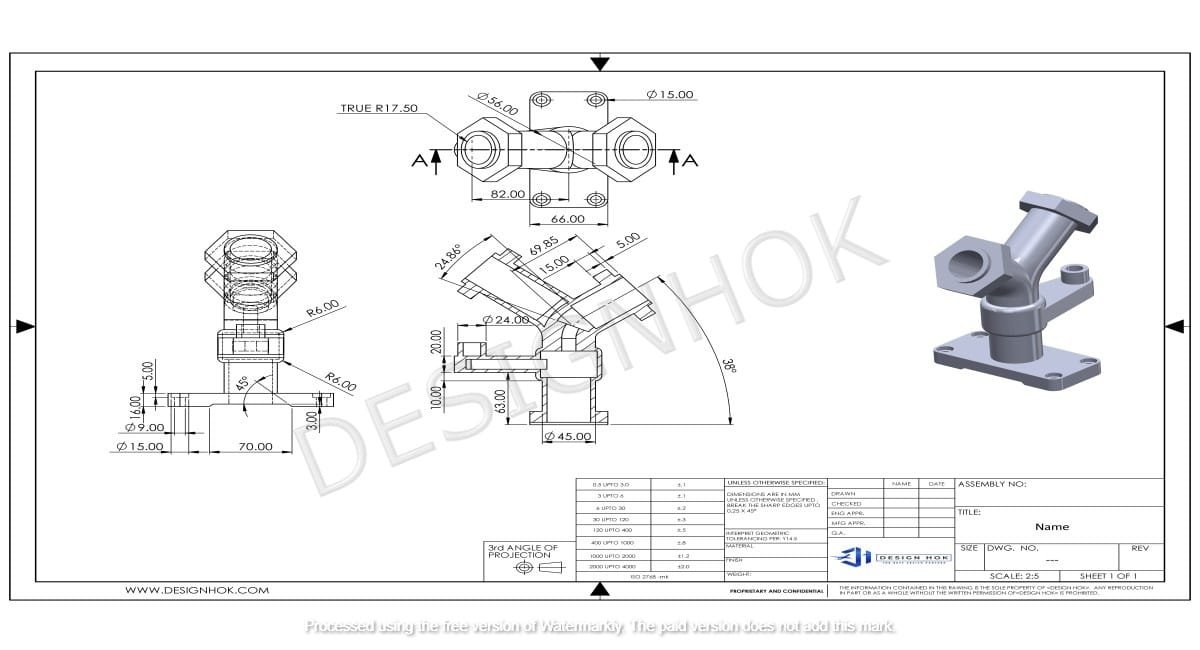

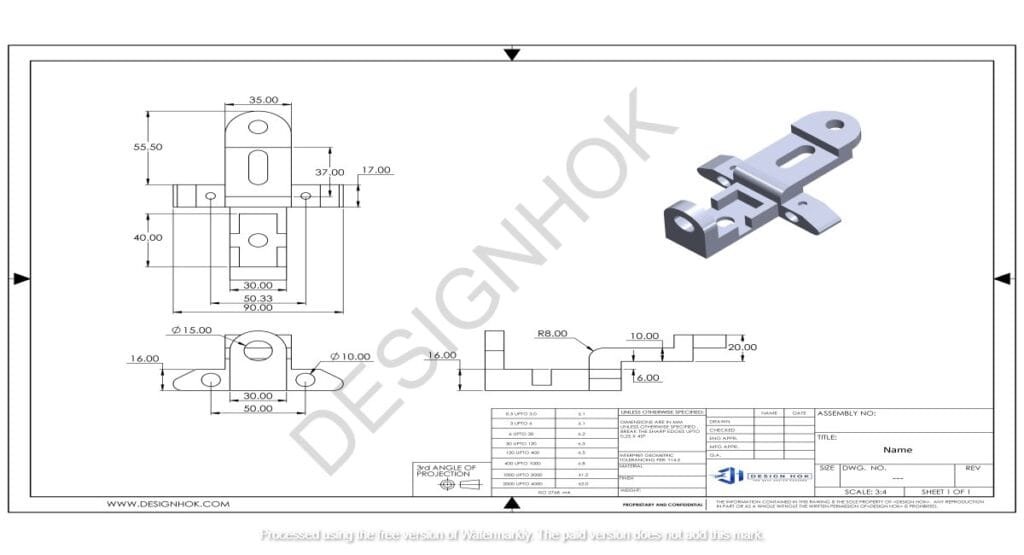

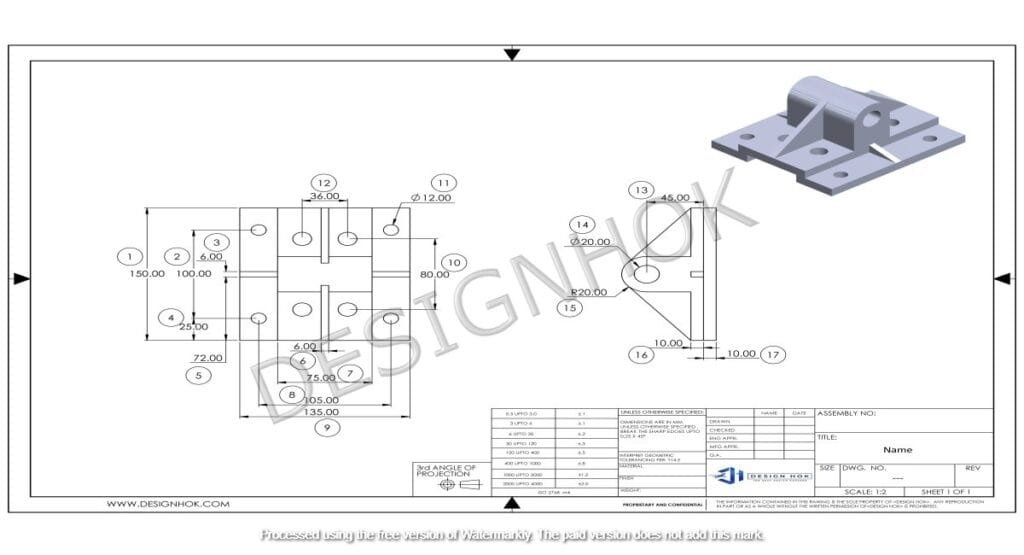

2. Computer-Aided Design (CAD)

CAD tools enable precise modeling of components, ensuring accurate dimensions and seamless integration.

3. Computational Fluid Dynamics (CFD)

CFD analyzes the behavior of fluids (air, water) interacting with structures and machines, critical in designing aerodynamic or hydrodynamic systems.

4. Material Testing Equipment

Equipment like tensile testers and fatigue analyzers ensures the chosen materials meet the design requirements.

Challenges in Mechanics-Based Design

1. Balancing Strength and Weight

Achieving a balance between structural integrity and lightweight design is crucial, especially in aerospace and automotive industries.

2. Adapting to New Materials

Innovative materials like composites and smart materials require updated design methodologies, posing a challenge to traditional mechanics-based approaches.

3. Sustainability Concerns

Designers must integrate eco-friendly practices without compromising performance, pushing the limits of mechanics principles.

Innovations in Mechanics-Based Design

- Smart Structures: Intelligent materials integrated with sensors adapt to changing environmental conditions, enhancing resilience and functionality.

- Additive Manufacturing: Mechanics principles are being adapted for 3D printing, revolutionizing how components are designed and produced.

- AI-Driven Optimization: Artificial intelligence accelerates design iterations by predicting performance based on mechanics simulations.

Benefits of Mechanics-Based Design

- Safety: Ensures structures and machines operate safely under all conditions.

- Durability: Extends the life of components by minimizing wear and tear.

- Efficiency: Optimizes energy use in machines and reduces material wastage in structures.

- Cost-Effectiveness: Prevents costly failures through predictive analysis and robust design.

Conclusion

Mechanics-based design is indispensable in modern engineering, serving as the foundation for innovation in both structures and machines. By adhering to core principles, leveraging advanced tools, and addressing emerging challenges, this approach ensures a future where engineering solutions are not only effective but also sustainable. From towering skyscrapers to intricate robotic systems, mechanics continues to shape a world that meets human needs while respecting environmental limits.

FAQs

1. What is mechanics-based design?

Mechanics-based design applies principles of mechanics, material science, and computational analysis to create efficient, durable, and safe structures and machines.

2. Why is stress and strain analysis important?

Stress and strain analysis ensures components remain within safe limits under forces, preventing structural failures and improving durability.

3. How does finite element analysis (FEA) contribute to mechanics-based design?

FEA simulates stresses, strains, and deformations in components, enabling engineers to optimize designs before production.

4. What role does material selection play in mechanics-based design?

Material selection ensures that components can withstand operational and environmental conditions, enhancing safety and performance.

5. How is sustainability integrated into mechanics-based design?

Sustainability is achieved by optimizing material use, energy efficiency, and adopting eco-friendly practices, ensuring long-term environmental benefits.