Milling Tools for Mechanical Product Development

In this world of engineering, accuracy and quality are more important than ever. Engineers have to ensure that their product is precise and durable. Now, if you’re building a mechanical part for large or small mechanical industries. The tools can make a major difference. Milling tools are the most important tools in mechanical product development. You can turn any computer Design HOK into real, physical parts by using this tool. These tools help us to achieve the correct shapes, size, and strength required for a mechanical product development. If engineers choose the wrong milling tools, it can cause huge problems such as longer project time, higher cost, and or even product failure, but if you select the right ones. You’ll save time, improve quality, and boost productivity. In this guide, you’ll understand why milling tools are important and the different types of tools available.

Why Milling Tools Are Important in Mechanical Product Development

Developing a mechanical product involves many steps — designing, prototyping, testing, and mass production. At each step, precision is necessary. Milling tools are used to shape raw materials into finished parts. Mechanical engineers use milling machines to cut, drill, slot, and contour materials such as steel, aluminum, brass, and polymers (plastic). These tools ensure that the final product matches the exact design specifications. Without accurate milling tools, products may have rough surfaces, incorrect dimensions, or weak structural integrity. This is why milling tools are so essential to every manufacturing process. The development of a mechanical product development involves many steps: prototyping, testing, and mass production. Each step is done with accuracy and precision. It’s used to shape a raw material into a finished part. In this whole process, mechanical engineers use milling machines to cut, drill, and contour materials such as steel, aluminum, and plastic. These tools make sure that the final product matches the exact design specification.

These tools not only help with cutting and shaping, but also affect:

- Production speed

- Product quality

- Overall cost

Here are a few most common milling tools used in mechanical product development.

1. End Mills

End mills are the most common and useful type of milling tools. It has edges on both sides (bottom and sides), which help the engineer to cut in multiple directions.

These tools come in different shapes:

- Flat end mills: It used for cutting flat surfaces and sharp edges.

- Ball-nose end mills: They are used for curved surfaces or 3D contours.

- Corner-radius end mills: They are used when you need smooth corners or rounded edges.

In mechanical product development, they use end mills for many purposes, such as cutting, slotting, or drilling. They are available in two versions: single-flute and multi-flute versions.

2. Face Mills

These mills are used when you need to remove a large amount of material quickly. These tools have multiple edges, and they’re excellent for creating flat surfaces. These mills are used in the first step of machining, where the goal is to prepare a flat surface before more detailed work begins.

Here are a few advantages of using Face Mill early:

- Accurate surface

- Consistent dimensions

- A smooth and professional finish

These mills are fast and powerful. It’s perfect for production units, where speed and quality are important.

3. Fly Cutters

These cutters are single-point cutting tools used for milling large and flat areas. It’s not like a face mill; it uses only one cutting blade.

Fly cutters work slower than face mills; they offer:

- High-quality surface

- Easy maintenance

- Cost-effictive

It’s ideal for startups seeking to reduce costs while maintaining quality.

4. Slab Mills

These milling tools have large cutters that are a mechanical product development for removing thick layers of material quickly.

These are strong and durable, and they’re mostly used for large blocks. It’s commonly used in rough machining.

Here are a few advantages of slab mills:

- It reduces time

- It prepares parts for finishing

- This tool improves efficiency in large industries.

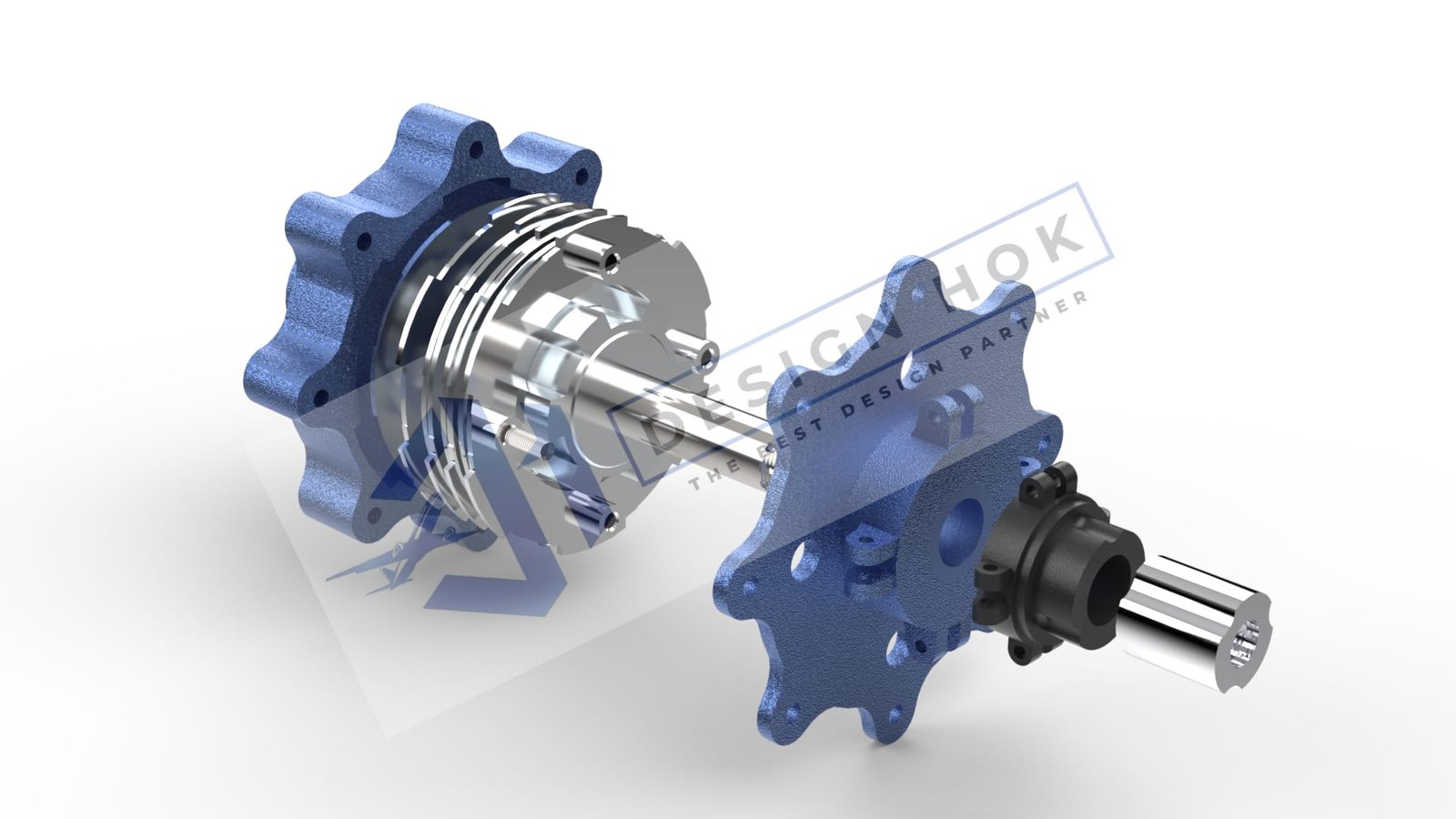

5. Gear Cutters

These cutters are essential components in mechanical product development, including engines, transmissions, and machines. These special tools cut precise gear teeth into metal parts. Each tooth must be shaped perfectly to ensure smooth motion and power transfer between gears. It may not be used in every project, but they are very important wherever rotational motion or power transmission is needed.

6. Thread Mills

It’s used to make internal and external threads. It can cut threads in both soft and hard materials without breaking easily. They are also flexible, as one thread mill can cut threads of different sizes by adjusting machine settings.

The few advantages of thread mills are that they are precise, clean, have less tool breakage, and are suitable for high-strength materials.

7. T-Slot Cutters

Mechanical products need slots to hold bolts and screws; that’s why engineers need T-slot cutters. These tools create T-shaped slots, which are commonly found on modular fixtures. T-slot cutters help engineers build products that are structurally stable, easy to assemble, and strong enough for repeated use.

8. Dovetail Cutters – For Precision Joints

This tool is used for precision joints. These joints are used to connect two parts with high strength. It is commonly used in fixture design and mechanical product development assemblies where parts must lock together.

9. Ball-Nose Cutters

These cutters are most commonly used for cutting smooth shapes and complex forms. Especially when creating molds, dies, or custom components. Ball-nose cutters are essential when working on modern product designs that have aerodynamic or organic shapes.

10. Reamers

A reamer opens an existing hole to achieve a tight fit for parts like bearings and shafts.

These reamers help:

- It improves hole accuracy

- It achieves better surface finishes

- It reduces vibration and assembly issues

Conclusion

In the development process, mechanical product development engineers use different milling tools for better accuracy. If they choose the right milling tool for product development, it helps us to work faster, improve quality, and reduce production costs. If you avoid poor-quality tools, then it will help you prevent costly delays, wasted materials, and design errors. The right set of tools not only increases productivity but also leads to better innovation and long-term success in mechanical engineering.

Real good information can be found on web site. “I said I didn’t want to run for president. I didn’t ask you to believe me.” by Mario M Cuomo.