Mechanical Machine Drawing for Design HOK plays a vital role in the design process, providing precise blueprints for manufacturing and constructing mechanical systems. Mechanical drawings are essential for Design HOK, ensuring clarity, accuracy, and a streamlined workflow. Significance, and steps involved in creating these drawings to enhance your design capabilities.

Mechanical Machine Drawing for Design HOK serve as the backbone of any engineering project, particularly in the realm of mechanical design. These drawings act as visual representations of machines or mechanical parts, providing crucial details such as dimensions, materials, tolerances, and manufacturing instructions. For firms like Design HOK, which focus on architectural and engineering excellence, mastering mechanical drawing is key to ensuring that complex designs translate seamlessly from concept to reality.

Importance of Mechanical Machine Drawing for Design HOK

Design HOK emphasizes innovation and precision, and Mechanical Machine Drawing for Design HOK align perfectly with this philosophy. This diagram is important for the following reasons:

Accuracy: Mechanical drawings provide exact specifications, minimizing the chances of errors during production. Whether it’s a small part of a machine or an entire system, the accuracy ensured by these drawings helps engineers and manufacturers maintain uniformity.

Communication: Drawings act as a universal language between designers, engineers, and manufacturers. They ensure that all stakeholders understand the intricacies of the project, reducing the risk of miscommunication.

Cost-Effectiveness: A well-prepared drawing eliminates guesswork during manufacturing, which can reduce waste and avoid costly mistakes. This ensures a more streamlined process, saving both time and resources.

Design Validation: Before a product is built, mechanical drawings allow engineers to validate whether the design will function as intended. This early identification of potential issues prevents major setbacks during production.

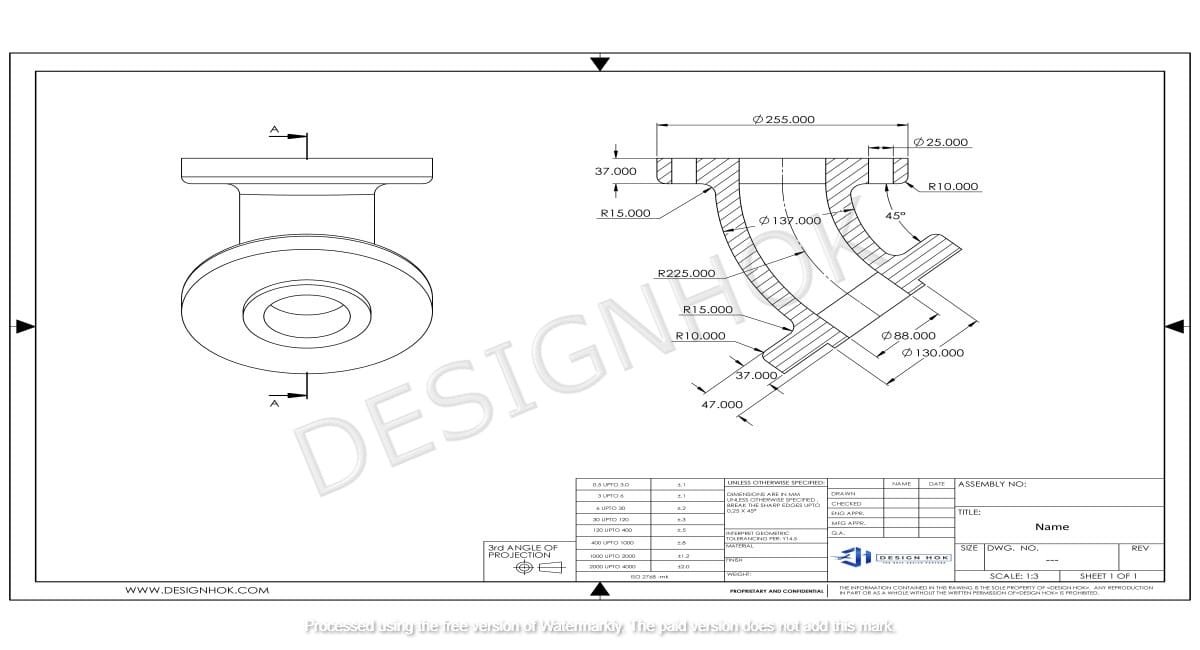

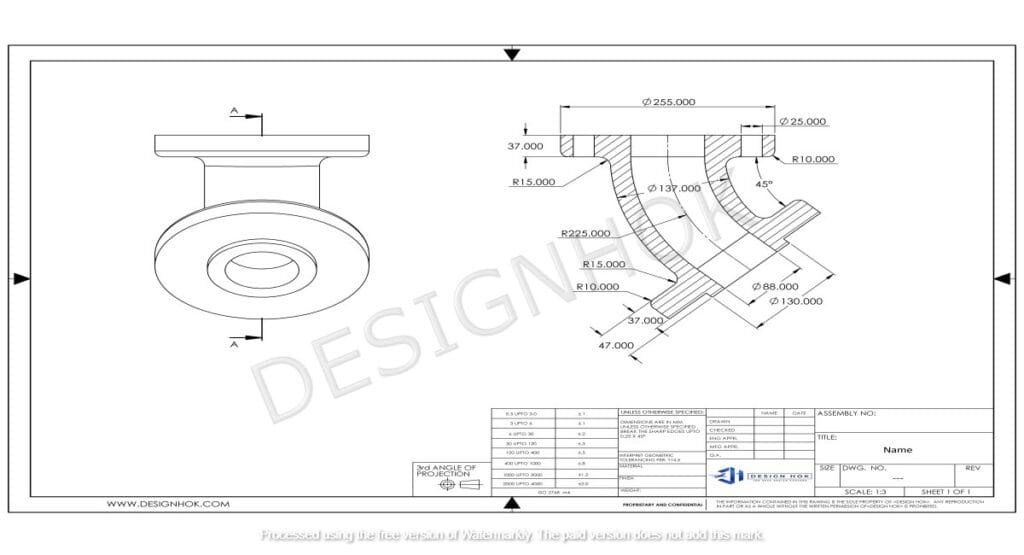

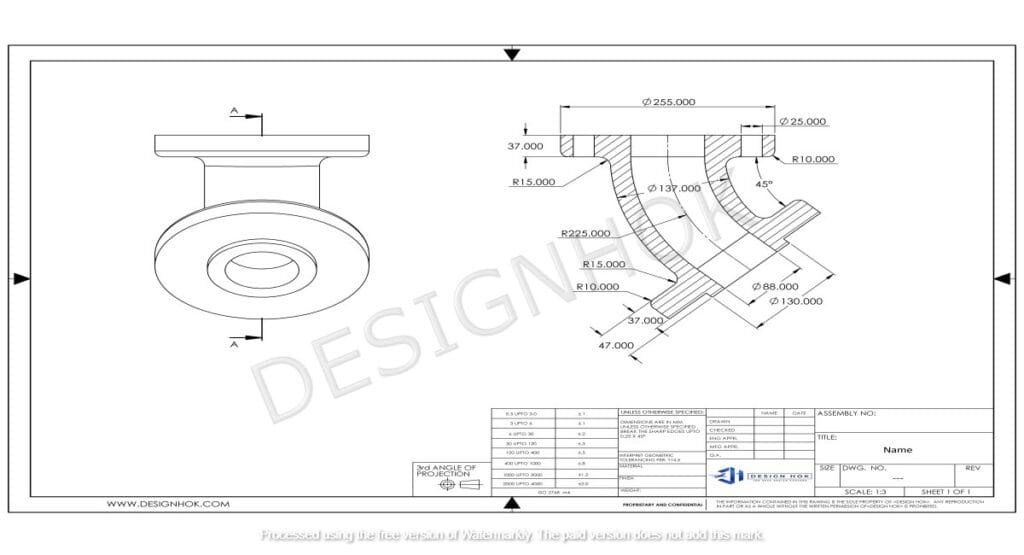

Components of a Mechanical Machine Drawing for Design HOK

Mechanical Machine Drawing for Design HOK follow a set of standardized conventions to ensure that they convey all necessary information. Some key components include:

Views:

Most drawings include multiple views of the machine part—top, side, front, and sometimes isometric (3D). These views give a complete perspective on how the part should be shaped and assembled.

Dimensions:

Exact measurements are provided to guide manufacturing. These dimensions show the size and scale of every feature on the part.

Tolerances:

Tolerances indicate the allowable deviations in measurements, ensuring that parts will fit together correctly even with small manufacturing variances.

Materials:

The drawing specifies the type of material to be used for each part, which can affect the manufacturing process and the part’s performance.

Annotations:

Annotations provide additional details like surface finish, hardness, and assembly instructions that aren’t immediately clear from the visual representation.

Steps to Create Mechanical Machine Drawings for Design HOK

Conceptualization:

The first step is to understand the requirements of the machine or part you’re designing. Define its purpose, functionality, and constraints.

Preliminary Sketching:

Start with rough sketches to visualize the basic structure of the machine. This stage allows you to explore multiple ideas before committing to a final design.

Use CAD Software:

Once you have a clear concept, use computer-aided design (CAD) software to create detailed, precise drawings. This software allows you to generate different views and adjust dimensions with ease.

Dimensioning and Annotations:

Add all necessary dimensions and annotations to ensure that the drawing is fully informative for manufacturers.

Review and Validation:

Finally, review the drawing with peers or senior engineers to catch any potential errors. Validation ensures that the design is ready for production.

Benefits of Using Mechanical Machine Drawings in Design HOK

Mechanical Machine Drawing for Design HOK provide a multitude of benefits that enhance the overall design process, particularly for firms like Design HOK:

Enhanced Collaboration:

Since mechanical drawings are highly detailed, they enable better collaboration between different departments, including designers, engineers, and construction teams.

Streamlined Production:

A complete mechanical drawing eliminates ambiguity, allowing manufacturers to produce parts with confidence and precision.

Innovation:

Having detailed drawings allows designers to focus on creative problem-solving, knowing that their ideas will be accurately translated into physical parts.

Conclusion

Mechanical Machine Drawing for Design HOK are fundamental to the design process, particularly for projects under Design HOK’s purview. These drawings offer the precision, clarity, and communication needed to transform innovative concepts into functional mechanical systems. By adhering to best practices in drafting, engineers can ensure that their designs are both manufacturable and efficient, leading to successful project outcomes.

FAQ

1. What is a mechanical machine drawing?

A mechanical machine drawing is a technical blueprint that shows the details of a mechanical part or system. It includes dimensions, materials, tolerances, and other important data necessary for manufacturing.

2. Why are mechanical drawings important for Design HOK?

Mechanical Machine Drawing for Design HOK are essential for ensuring accuracy and clarity in the design process. They help communicate complex designs to engineers and manufacturers, reduce errors, and streamline production.

3. What software is used for mechanical machine drawings?

Most mechanical machine drawings are created using CAD (Computer-Aided Design) software like AutoCAD, SolidWorks, or CATIA. These tools help in generating precise, scalable designs.

4. How do mechanical drawings help in reducing costs?

By providing detailed specifications, mechanical drawings reduce the chances of errors in manufacturing, which helps in avoiding costly mistakes and minimizes waste.

5. What are the key components of a mechanical drawing?

Key components include views (top, side, and front), dimensions, tolerances, materials, and annotations. Each of these provides important information for the manufacturing process.