Introduction

Mechanical designing is just like a spine for mechanical engineering. Creating machines, tools, and products; all this stuff makes our lives easier day by day. Every mechanical product always needs a design, for example, an engine, screwdrivers, or a wind turbine.

You may think mechanical designing is all about creating complex designs, but it’s not like this. It’s about finding simple and practical solutions for real-world problems to make things safe. Every company follows a different process, but the target is always the same: to keep things safe and easy to use. Let’s explore how the mechanical design works.

At Design Hok, we believe every great product starts with a great design hok. Our engineers combine creativity and technology to deliver designs that are functional, cost-effective, and future-ready.

Use of Mechanical Design

In this modern world, you may see mechanical design everywhere. All those products that move, support heavy loads, or perform any specific function have always first gone through the design process.

- Automotive Industry

They design and modify the car engines, brakes, and improve the body structure of cars. They also focus on aerodynamics.

- Manufacturing Industry

In this industry, mechanical designers create automated systems, robots, and tools that make products faster and more precise. It also includes factories and production units.

- Power Sector

They design turbines, compressors, and renewable energy sources such as wind turbines or hydro turbines. It also helps to improve performance and reduce the energy cost.

Steps in the Mechanical Design Process

Engineers follow some key steps while designing a product from start to end.

1. Defining the Problem

Designers always find a real-world problem that has to be solved.

For example:

- How can we make an engine that reduces the cost of fuel?

- How can we build a lighter and cheaper engine?

Engineers always understand the requirements of the client. This step gives a clear direction and makes sure that time and money are spent.

2. Generating New Ideas

Once an engineer understands the problem, they start generating ideas. This step involves creativity and experience.

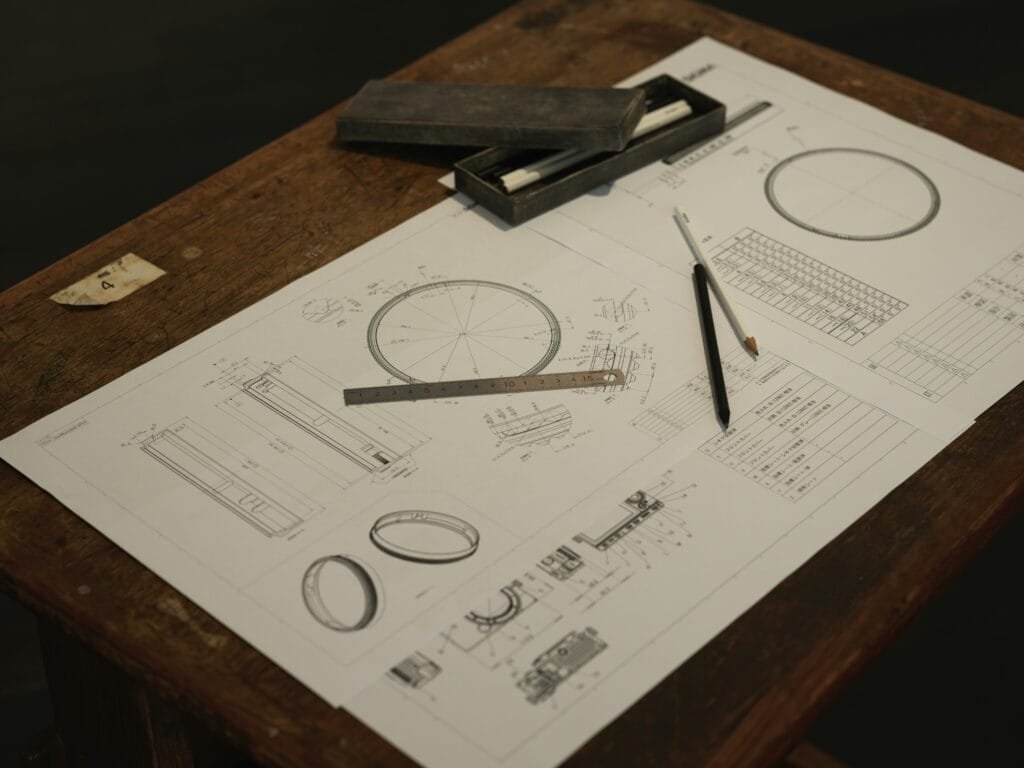

Mechanical designing design different rough sketches and discuss with their team, and analyze what would be the best option. No idea is ignored at that time, even the simplest ideas can solve the problems. Brainstorming encourages innovation and helps engineers explore multiple ways to solve a single problem.

3. Choosing the Best Solution

Engineers collect all ideas, and they decide which one is the best and most practical.

They think about:

- How easy it is to manufacture

- How safe is it to use

- How reliable will it be in real-life conditions?

You may think the advanced ideas are the best, but it’s not like this. The best idea is one that costs less, works safely, and is precise.

4. Beta Version

When engineers design the first real version, this version is called a beta version or a prototype model. It’s the physical model made with 3D printing. The prototype helps engineers to test how the machine works in real-time, and it solves the problem or not.

5. Testing

Once the prototype is ready, it’s time for testing. In older times, engineers had to build physical models for every test. Today, thanks to modern software, much of this testing is done virtually.

They use Virtual tools to check how the design works:

- Heat and temperature changes

- Mechanical designing stress and load

- Vibration, movement, or pressure

This helps them to test the performance without wasting any material, and it also saves cost.

6. Refining the Design

If engineers find any flaws or errors in the design, they readjust the shape, change the material, and improve the structure so the product can perform better. This step is continuously repeated until the problem is solved. Only after successful inspection is the design ready.

Key Things to Keep in Mind During Mechanical Design

A successful design is a mechanical designing that is balanced properly, such as it’s safe and low-cost.

- Functionality

The product must perform its job perfectly every time.

- Safety

It should be safe for users and meet all local and international standards.

- Cost

High-quality and affordable mechanical designing is always a great design.

- Manufacturability

The product should be easy to produce, assemble, and repair.

- Strength

It must handle pressure, wear, and daily use without breaking.

- Material Choice

Always choose the right material, which is durable and cost-effective.

Tools Used by Mechanical Designers

In this modern world, most of the mechanical designing relies heavily on digital tools, which is actually helpful and saves a lot of time and cost. These tools also help you to visualize your idea in VR before making a physical model

Common tools include:

- CAD (Computer-Aided Design) Software: This tool is used to create 2D and 2D models of components.

- Simulation Software: Engineers use this tool to check the durability, strength, and how much temperature it can withstand.

- Prototyping Tools: It prints the model that helps to build the sample products for testing.

- Project Management Tools: It is used to track progress, timelines, and manage tasks with teams.

This technology makes the design process faster and more reliable.

The Future of Mechanical Design

In the revolutionized world, most designs will focus on being sustainable and creating machines that use less power and produce less waste. Mechanical designing is growing rapidly, which is why engineers generate new ideas and make more reliable and smarter products. All of this is because of the AI world.

Conclusion

Mechanical designing isn’t just about making a product. It’s also about using your imagination and clear thinking to come up with smart ways to solve real problems. Engineers find a real-world problem and then brainstorm new ideas and choose the best solution. Engineers can now make their ideas a reality faster than ever thanks to tools like CAD software, simulations, and rapid prototyping.

Mechanical designing shapes the world around us, from simple tools we use at home to heavy machines used in industry.

There is perceptibly a lot to identify about this. I consider you made some nice points in features also.

I like what you guys are up also. Such clever work and reporting! Keep up the excellent works guys I have incorporated you guys to my blogroll. I think it will improve the value of my web site :).