Mechanical Design Engineer: What They Do and Common Questions

Mechanical Design Engineer: What They Do and Common Questions

Mechanical Design Engineer: What They Do and Common Questions

what a mechanical design engineer does, including their main tasks and the skills they need. It also features a short FAQ section that answers basic questions about this important role, making it easy to understand how these engineers help create the products and systems we use every day.

What is a Mechanical Design Engineer?

In the realm of engineering, the role of a mechanical design engineer stands out as a key contributor to the creation and development of machines, tools, and systems that drive various industries. These professionals combine their technical expertise with creativity to design mechanical components and systems that meet specific functional requirements. But what exactly does a mechanical design engineer do, and why is this role so crucial in today’s technological landscape? This blog delves into the responsibilities, skills, and importance of mechanical design engineers.

The Role of a Mechanical Design Engineer

A mechanical design engineer is responsible for designing, developing, and testing mechanical devices and systems. This could range from small components like gears and sensors to large systems such as engines and industrial machinery. The primary objective is to create products that function efficiently, are durable, and meet the intended performance standards.

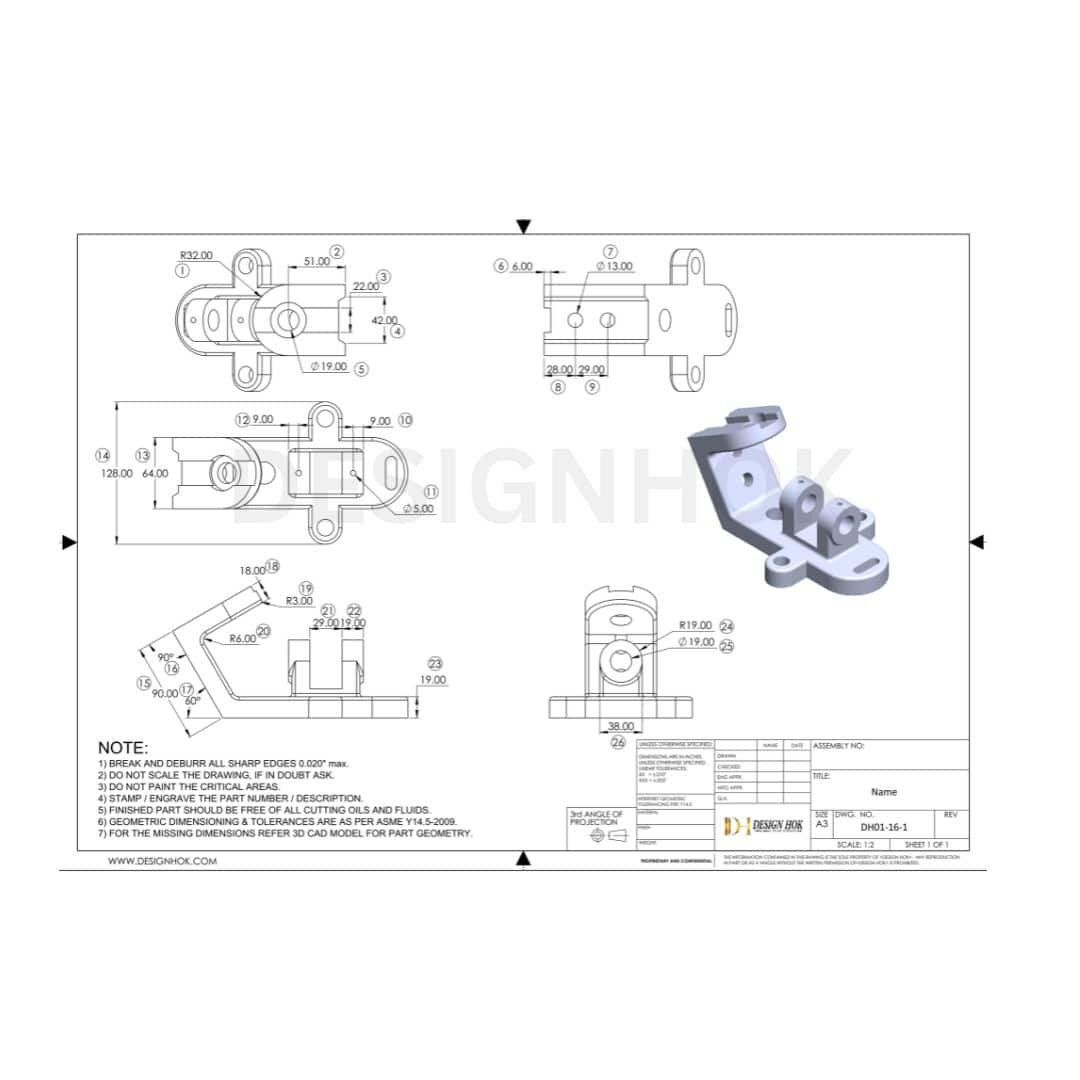

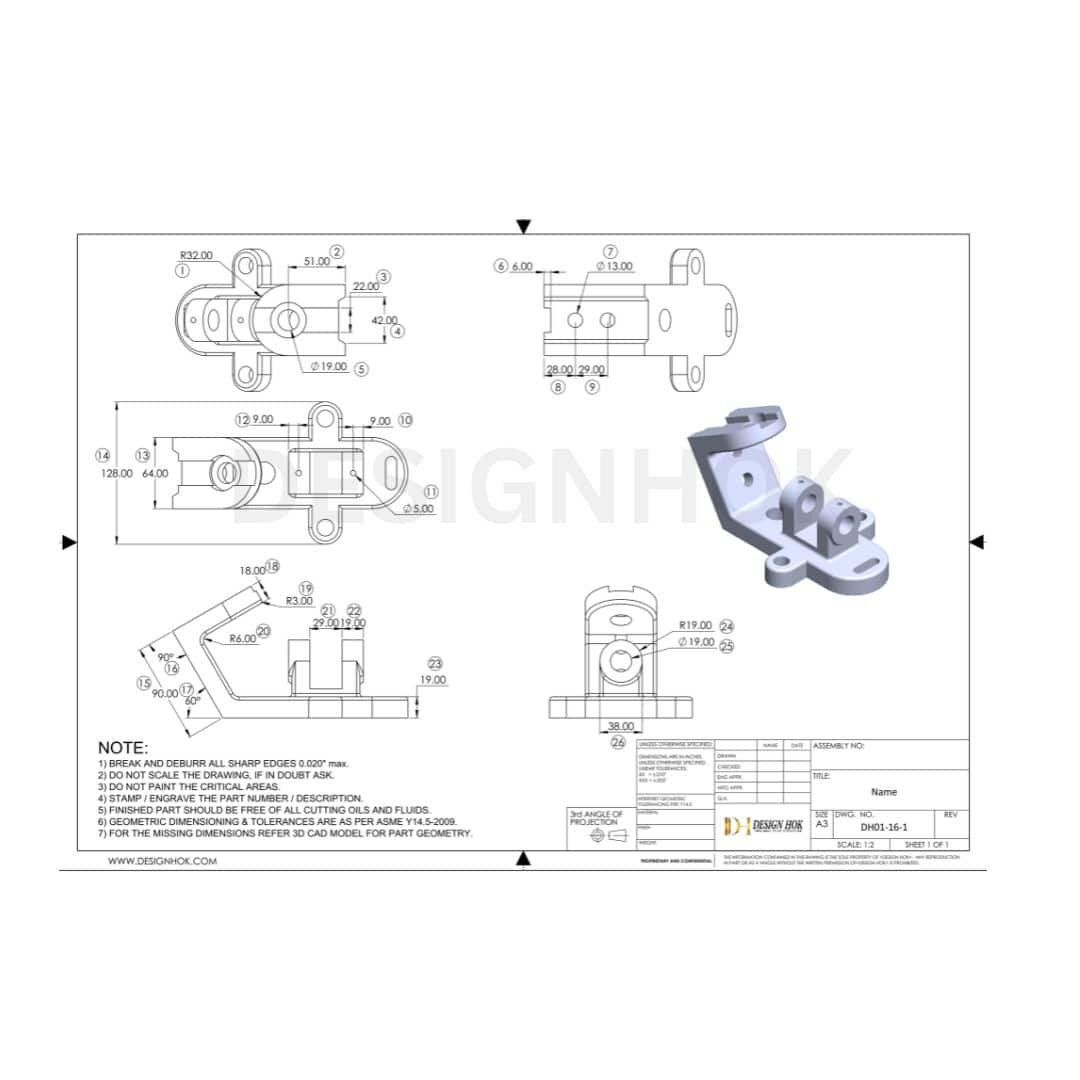

The design process typically begins with understanding the requirements of the project. This involves discussions with clients or stakeholders to determine the purpose, functionality, and constraints of the product. Based on this information, the mechanical design engineer creates initial concepts and sketches, which are then developed into detailed designs using Computer-Aided Design (CAD) software.

Once the design is created, it undergoes various analyses to ensure it meets all specifications. Engineers might conduct simulations to predict how the product will perform under different conditions, such as stress, heat, and wear. They also consider factors like material selection, manufacturing processes, and cost-effectiveness during this phase.

After the design is finalized, prototypes are often built and tested to validate the design’s functionality and identify any areas that need improvement. If necessary, the design is refined and optimized before it moves into full production. Throughout this process, mechanical design engineers work closely with other engineers, such as electrical and civil engineers, as well as with manufacturing teams to ensure that the final product meets all quality and performance standards.

Key Responsibilities of a Mechanical Design Engineer

-

Key Responsibilities of a Mechanical Design Engineer

-

Conceptual Design: One of the first steps in a mechanical design engineer’s work is to develop concepts for new products or systems. This involves brainstorming ideas, sketching initial designs, and evaluating different approaches to solving the problem at hand.

-

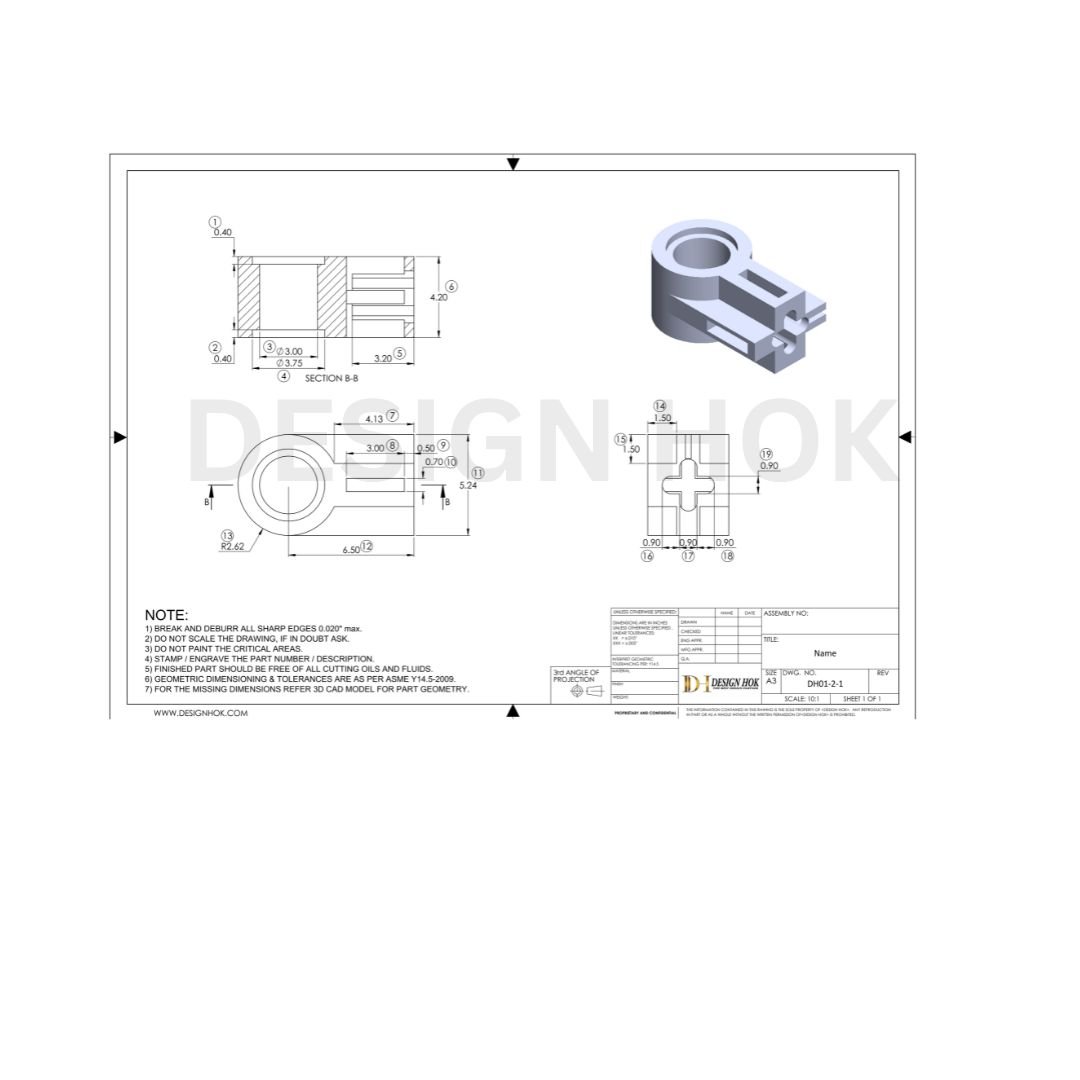

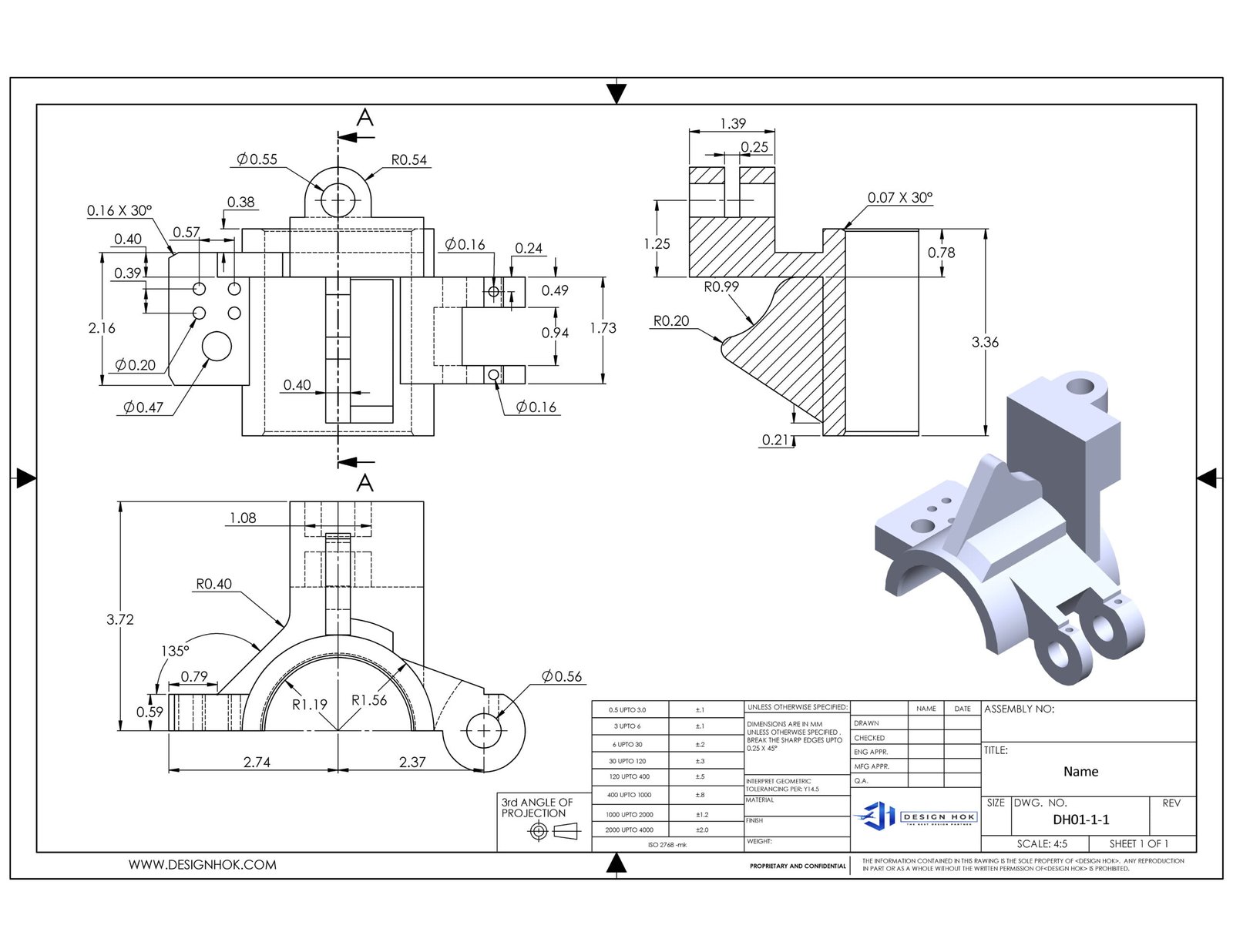

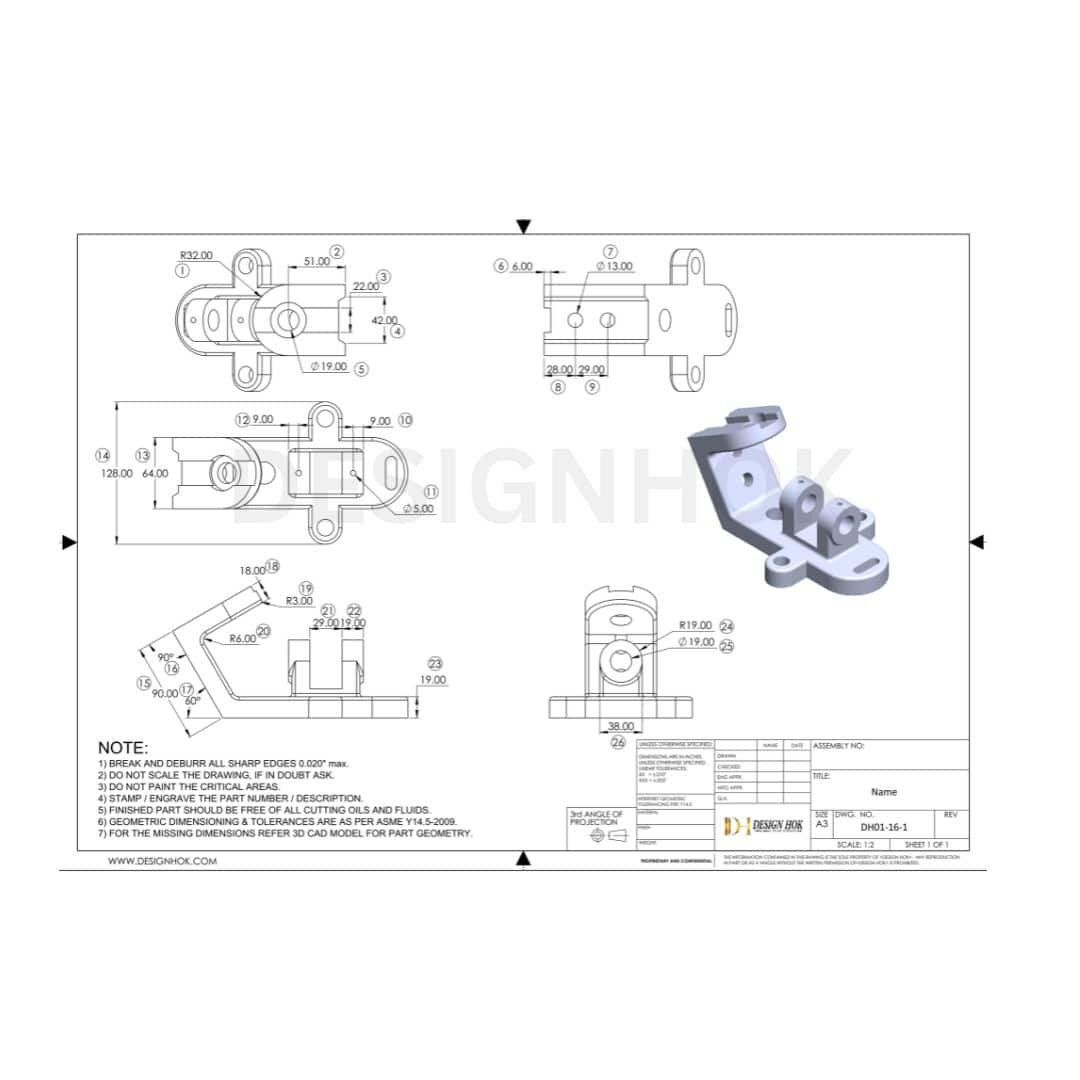

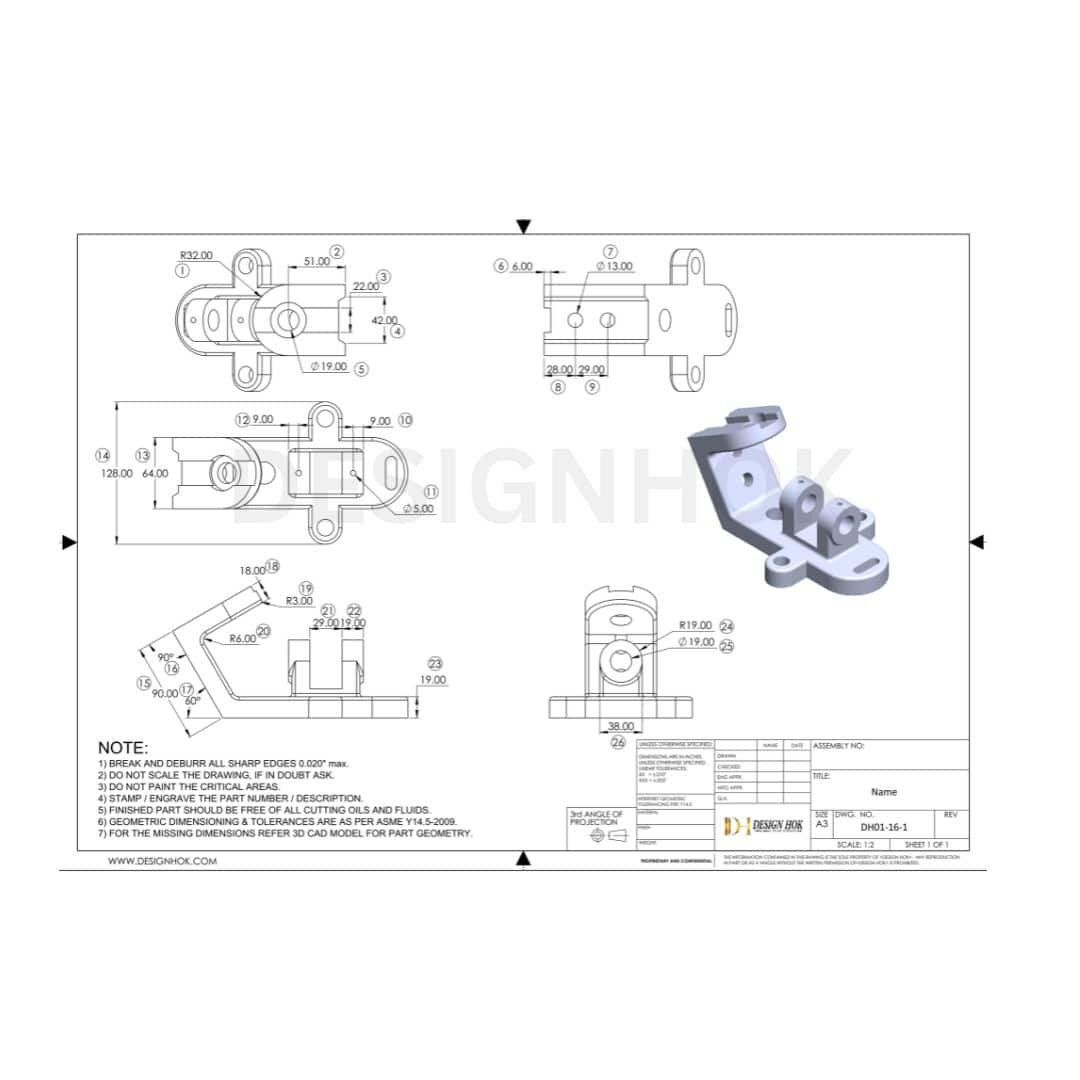

Detailed Design and CAD Modeling: Once a concept is chosen, the engineer creates detailed designs using CAD software. These designs include precise measurements, materials, and specifications that guide the manufacturing process. CAD models also allow for simulations and analyses to predict the product’s behavior in real-world conditions.

-

Prototyping and Testing: After the design is completed, a prototype is often built to test its performance. The engineer oversees the creation of this prototype, conducts tests, and analyzes the results to determine if the design meets all necessary requirements.

-

Collaboration: Mechanical design engineers regularly collaborate with other professionals, including engineers from other disciplines, project managers, and manufacturing teams. This collaboration ensures that the design integrates seamlessly with other systems and meets the overall project goals.

-

Documentation and Reporting: Throughout the design process, engineers are responsible for documenting their work, including design calculations, test results, and any modifications made to the design. This documentation is crucial for future reference and for ensuring that the design meets all regulatory and safety standards.

-

Project Management: In some cases, mechanical design engineers also take on project management roles, where they oversee the entire design process from conception to production. This involves managing timelines, budgets, and resources to ensure that the project is completed on time and within budget.

-

Essential Skills and Qualifications

To be successful as a mechanical design engineer, certain skills and qualifications are essential. A strong foundation in mechanical engineering principles is a must, typically obtained through a bachelor’s degree in mechanical engineering or a related field. Advanced degrees can further enhance an engineer’s expertise and career prospects.

Proficiency in CAD software, such as AutoCAD, SolidWorks, or CATIA, is crucial for creating and analyzing designs. Knowledge of materials science, thermodynamics, and fluid dynamics is also important, as these areas often influence design decisions.

Strong problem-solving skills are essential, as engineers must be able to identify and address potential issues throughout the design process. Attention to detail is critical, as even small errors in the design can lead to significant problems in the final product.

Good communication skills are also important, as mechanical design engineers frequently work in teams and must be able to explain their ideas and findings clearly. Additionally, an understanding of manufacturing processes and constraints is valuable, as it helps engineers create designs that are not only functional but also feasible to produce.

The Importance of Mechanical Design Engineers

Mechanical design engineers are at the heart of innovation in many industries. Their work ensures that products are not only functional but also efficient, safe, and reliable. Without their expertise, many of the machines and tools we rely on daily would not exist, or they would not perform as well.

In industries like automotive, aerospace, robotics, and manufacturing, mechanical design engineers play a pivotal role in developing new technologies and improving existing ones. Their contributions help companies stay competitive by creating products that meet the ever-evolving demands of the market.

Moreover, as the world increasingly focuses on sustainability, mechanical design engineers are tasked with developing solutions that reduce energy consumption, minimize waste, and use environmentally friendly materials. This makes their role even more crucial in addressing global challenges such as climate change.

Conclusion

Mechanical design engineers are essential to the creation and optimization of the machines and systems that power our world. Their role involves a blend of creativity, technical expertise, and collaboration, all aimed at bringing innovative ideas to life. As industries continue to evolve and new challenges emerge, the demand for skilled mechanical design engineers will only grow, making it an exciting and rewarding career path for those interested in engineering and design.

g innovative ideas to life. As industries continue to evolve and new challenges emerge, the demand for skilled mechanical design engineers will only grow, making it an exciting and rewarding career path for those interested in engineering and design.

FAQ: Mechanical Design Engineer

1. What does a mechanical design engineer do?

A mechanical design engineer designs and develops mechanical systems and components, ensuring they function efficiently, reliably, and safely.

2. In which industries do mechanical design engineers work?

They work in various industries, including automotive, aerospace, manufacturing, energy, and consumer goods.

3. What tools do mechanical design engineers use?

They commonly use CAD software like AutoCAD, SolidWorks, and Revit to create detailed designs and models.

4. What skills are important for a mechanical design engineer?

Key skills include problem-solving, strong analytical abilities, proficiency in design software, and a solid understanding of mechanics and materials science.

5. How do mechanical design engineers ensure their designs work?

They perform simulations, stress analysis, and prototyping to test and refine their designs before production.

6. Do mechanical design engineers work alone?

No, they often collaborate with other engineers, designers, and team members to ensure all systems work together seamlessly.

7. Why are mechanical design engineers important?

They play a crucial role in creating efficient, safe, and innovative products and systems that impact our daily lives.