One of the important parts of engineering is mechanical design and analysis. You are able to create machines, tools, and systems. So, these processes result in the creation of safe, efficient, and reliable products. You have to create a thoughtful design and analysis to meet the demands of the client.

Understanding Mechanical Design and Analysis

You have to make and improve mechanical systems in mechanical design and analysis. You begin with an idea and finish with an end product. Your aim should be to create strong and safe parts that last longer. This field is a mix of creativity, practical engineering knowledge, and high-level problem-solving skills.

Steps in Mechanical Design

1. Conceptualization

This is the initial stage where the idea is made. Engineers wonder how the system should behave. They create sketches and plan how to link the parts. So, this stage involves planning and defining the problem that the design will solve

2. Detailed Design

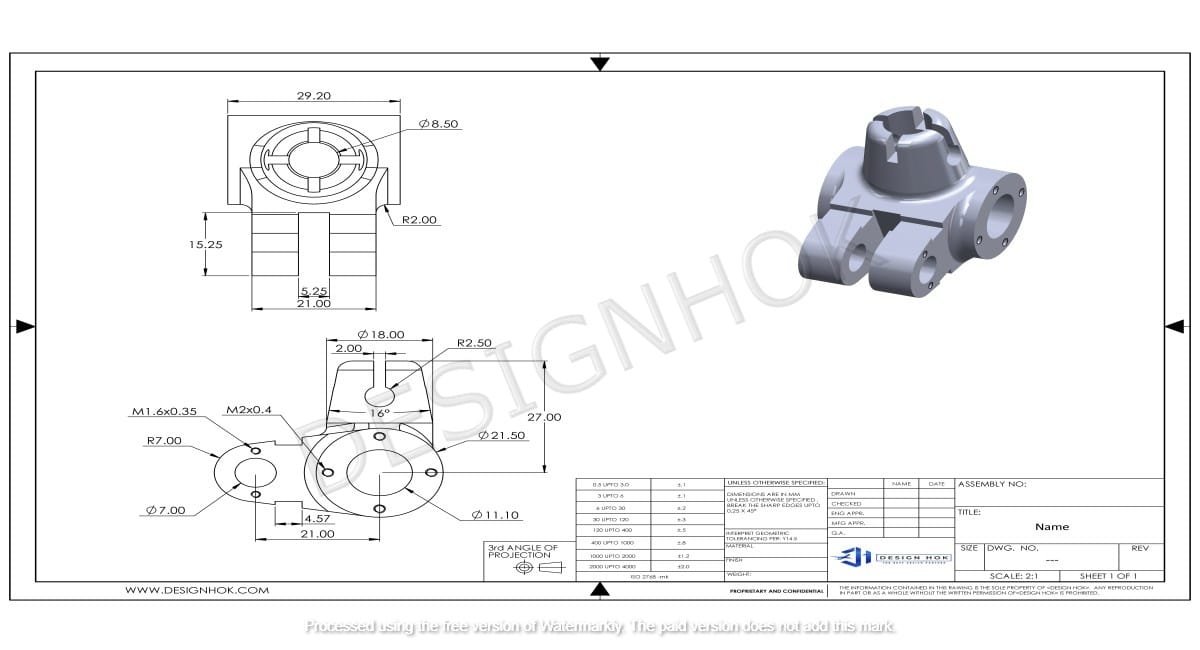

CAD software helps you create exact models. This is why tools provide you with an idea of the look and fitness of the model. You improve the design by taking exact measurements, material specifications, and tolerances.

3. Prototyping

You create a prototype to experiment with the design. This helps you solve problems and improve the product. Prototypes let engineers know the errors in the design. So, they may make several prototypes to improve.

4. Testing and Refinement

The prototype is tested. Safety and performance are checked. The design is improved until it works well. Engineers keep on testing until the prototype meets all the needs.

Key Areas of Mechanical Design and Analysis?

- Stress Analysis

Checks if parts can handle force without breaking. So, you can identify weak spots in the design. - Thermal Analysis

Studies how heat affects the system. This is why engineers check whether the design can handle the thermal expansion. - Vibration Analysis

Look at how movement or shaking impacts the system. They check resonance as it can increase vibrations and result in failure.

4. Fatigue Analysis

Test how long parts last under repeated use. You can make sure that parts will not fail early.

Importance

- Safety is improved by finding weak points.

- You can save time and energy by being productive

- Innovation helps you make new products

- Systems are able to last longer if they are reliable.

- Companies can beat competitors by creating innovative designs

Uses

- Automotive includes engines and vehicle parts.

- Aerospace includes aircraft and propulsion systems.

- Manufacturing includes machines and tools.

- Robotics includes robots and automated systems.

- Consumer products include appliances and gadgets.

Conclusion

So, mechanical design and analysis can help you turn your thoughts into reality. They make systems safe, strong, and efficient. Moreover, they have applications in a number of industries every day.

So to sum up, mechanical design and analysis are important to create products. These products are functional as well as safe, reliable, and efficient. This is beneficial for society as a whole.

FAQs

- Give a comparison between design and analysis?

You create systems with the help of design. On the other hand, analysis gives you their performance. - What is the importance of prototyping?

You are able to find faults in the design before mass production. - How does stress analysis help?

You test that whether the parts can handle the load or not. - Name the industries that use these processes?

There are several areas where you use these processes. This includes automotive, aerospace, manufacturing, robotics, and consumer products. - What is the need for CAD software?

You are able to let engineers make detailed models.