Explore the concept of mechanical advantage in machine design and Design Hok can leverage it to enhance the efficiency and performance of its products.

Introduction:

In the world of engineering and design, the concept of is fundamental. It is the principle that allows machines to perform tasks more efficiently by amplifying the force applied to them. For companies like Design Hok, understanding and utilizing Mechanical Advantage in Machine Design is crucial in developing machines that are not only effective but also optimized for performance. This blog will delve into what Mechanical Advantage in Machine Design is, how it applies to machine design, and the ways in which Design Hok can harness this principle to create superior products.

What is Mechanical Advantage in Machine Design?

Mechanical advantage is a measure of the force amplification achieved by using a tool, mechanical device, or machine system. In simple terms, it is the factor by which a machine multiplies the force put into it. The concept is essential in understanding how different machines work and how they can be designed to perform specific tasks with greater efficiency.

Mechanical advantage is usually calculated using the formula:

Mechanical Advantage (MA)=Output Force Input Forcetext{Mechanical Advantage (MA)} = frac{text{Output Force}}{text{Input Force}}Mechanical Advantage (MA)=Input Force Output Force

A higher Mechanical Advantage in Machine Design means that less input force is required to achieve a desired output force, making the machine more efficient in performing its task.

Types of Mechanical Advantage in Machine Design

There are two main types of mechanical advantage: Ideal Mechanical Advantage (IMA) and Actual Mechanical Advantage (AMA).

Ideal Mechanical Advantage (IMA):

- This is the theoretical mechanical advantage of a machine, assuming no friction or other losses. It is calculated based on the geometry of the machine, such as the length of levers or the number of pulleys.

Actual Mechanical Advantage (AMA):

- This is the real-world mechanical advantage that accounts for friction, wear, and other inefficiencies. AMA is usually lower than IMA due to these factors but gives a more accurate representation of the machine’s performance.

Mechanical Advantage in Machine Design

Mechanical advantage is a critical consideration in the design of various machines and devices. By understanding and applying this principle, Design Hok can create machines that are more efficient, require less energy, and are easier to operate.

1. Levers:

Levers are one of the simplest machines that use Mechanical Advantage in Machine Design. By increasing the length of the lever arm, a small input force can be magnified to lift or move a much larger load. This principle is used in many tools and machines, such as crowbars, pliers, and seesaws.

2. Pulleys:

Pulleys are another example of a simple machine that utilizes mechanical advantage. By using multiple pulleys in a system, the amount of force needed to lift an object can be significantly reduced. This is especially useful in applications like cranes and elevators, where heavy loads need to be lifted with minimal effort.

3. Gears:

Gears are used to transmit torque and change the speed or direction of motion. By using gears of different sizes, the mechanical advantage can be altered to either increase the speed or amplify the force, depending on the requirements of the machine. This principle is widely used in automotive transmissions and industrial machinery.

4. Inclined Planes:

An inclined plane, such as a ramp, allows a heavy object to be lifted by applying a smaller force over a longer distance. This reduces the amount of force needed, making it easier to move the object. Inclined planes are commonly used in loading docks, construction sites, and even in everyday items like wheelchair ramps.

Approach to Mechanical Advantage in Machine Design

For Design Hok, the concept of mechanical advantage is more than just a theoretical principle—it’s a practical tool for creating innovative and efficient designs. By integrating mechanical advantage into the design process, Design Hok can develop machines that not only perform better but also offer significant advantages in terms of energy efficiency, cost savings, and user-friendliness.

1. Efficiency in Design:

By maximizing mechanical advantage, Design Hok can create machines that require less input energy, leading to greater efficiency. This is particularly important in industries where energy costs are a significant concern.

2. Enhanced Performance:

Machines designed with a high mechanical advantage can perform tasks more effectively, whether it’s lifting heavier loads, transmitting more torque, or moving objects more quickly. This leads to improved overall performance and reliability.

3. User-Centric Design:

Machines that leverage mechanical advantage are often easier to use, requiring less physical effort from the operator. This is a key consideration in creating user-friendly products that are accessible to a wider range of users.

Conclusion:

Understanding and applying the concept of Mechanical Advantage in Machine Design is essential for any design-focused company, and Design Hok is no exception. By integrating this principle into machine design, Design Hok can create products that are not only efficient and high-performing but also user-friendly and cost-effective. Whether through the use of levers, pulleys, gears, or inclined planes, the power of mechanical advantage can transform the way machines are designed and used, leading to innovative solutions that meet the demands of today’s market.

FAQs

1. What is mechanical advantage?

Mechanical advantage is the factor by which a machine multiplies the input force to achieve a greater output force. It allows machines to perform tasks more efficiently by reducing the effort required.

2. How is mechanical advantage calculated?

Mechanical advantage is calculated using the formula:

Mechanical Advantage (MA)=Output ForceInput Forcetext{Mechanical Advantage (MA)} = frac{text{Output Force}}{text{Input Force}}Mechanical Advantage (MA)=Input ForceOutput Force

A higher mechanical advantage means the machine is more efficient in amplifying the input force.

3. What are the types of mechanical advantage?

There are two main types: Ideal Mechanical Advantage (IMA), which is the theoretical advantage without considering friction, and Actual Mechanical Advantage (AMA), which accounts for real-world inefficiencies like friction and wear.

4. How does mechanical advantage apply to machine design?

Mechanical advantage is used in designing machines to make them more efficient, requiring less input force to perform tasks such as lifting, moving, or transmitting force.

5. What are some examples of machines that use mechanical advantage?

Common examples include levers, pulleys, gears, and inclined planes. These simple machines use mechanical advantage to make tasks easier by amplifying the input force.

6. Why is mechanical advantage important in machine design?

Mechanical advantage is crucial because it allows designers to create machines that are more efficient, cost-effective, and easier to operate. It enhances the performance and usability of the machine.

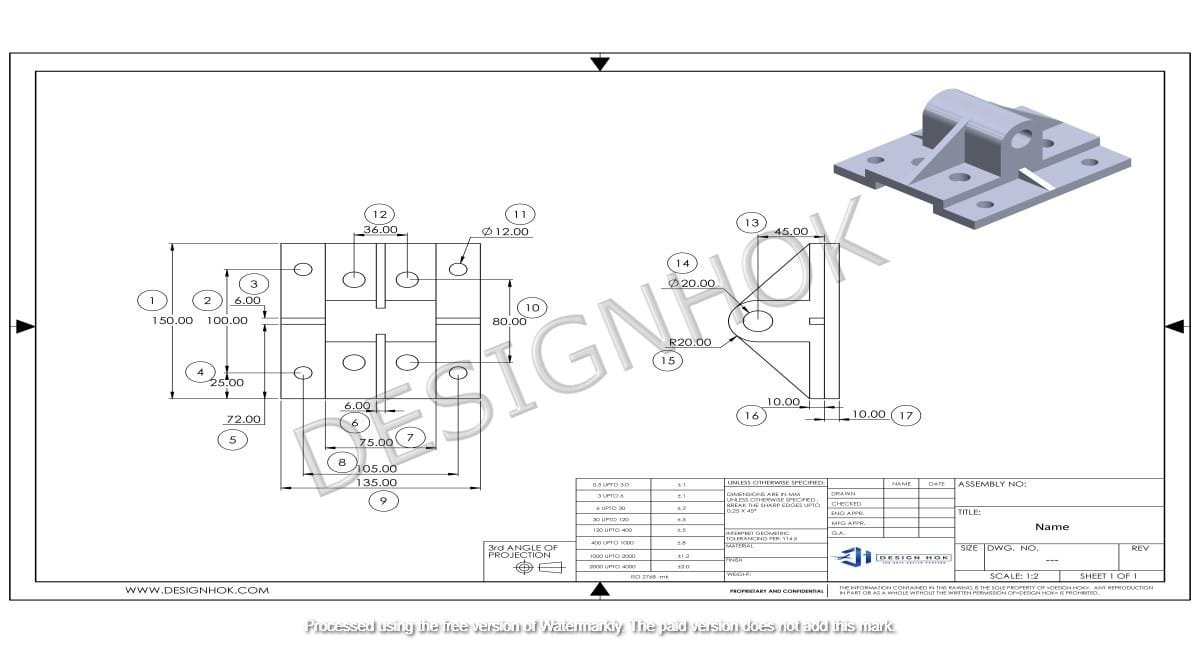

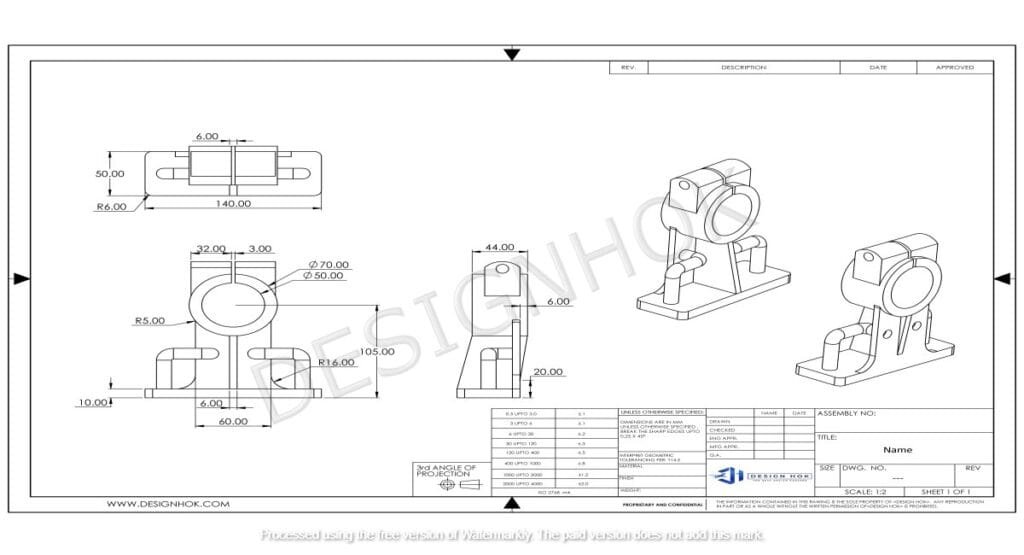

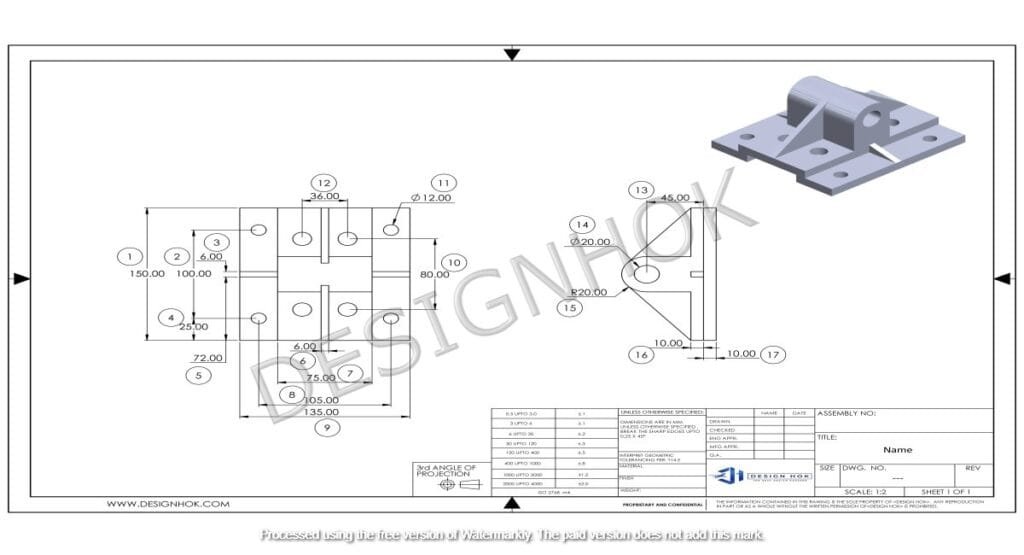

7. How does Design Hok use mechanical advantage in its designs?

Design Hok integrates mechanical advantage into its designs to develop machines that are more efficient, perform better, and are user-friendly. By optimizing mechanical advantage, Design Hok can create innovative and effective products.

8. Can mechanical advantage reduce energy consumption in machines?

Yes, by maximizing mechanical advantage, machines can perform tasks with less input energy, leading to reduced energy consumption and greater overall efficiency.

9. What role do gears play in mechanical advantage?

Gears transmit torque and change the speed or direction of motion. By using gears of different sizes, the mechanical advantage can be adjusted to either increase speed or amplify force, depending on the machine’s requirements.

10. How does mechanical advantage contribute to user-friendly design?

Machines with a higher mechanical advantage require less physical effort from the user, making them easier to operate. This contributes to a more user-friendly design, accessible to a wider range of users.