Description:

General assembly design is a key part of engineering. It brings separate parts together to form a complete product. The process ensures that items are strong, efficient, and safe. Many industries depend on it to build reliable systems.

Apart from that, this process also reduces errors in the design. So, engineers can identify mistakes and save costs by planning. An assembly design also minimizes production time and lowers material waste. These are the reasons that assembly design is the core of modern engineering.

What is General Assembly Design?

General assembly design is the method of fitting parts and sub-assemblies into one product. It is more than designing single pieces. It studies how all parts connect and work together. From machines to electronics to buildings, this process ensures products last and perform well.

Why is General Assembly Design Important?

This design process improves quality. You can easily identify faults and prevent delays in manufacturing. You are able to minimize waste and errors. It makes products easy to build and ensures smooth performance. Good assembly planning also speeds up production.

Core Principles of General Assembly Design

There are some basic rules for effective design. You must keep the design simple, which results in fewer mistakes. Also, utilize those parts that you can replace easily. Standard components save time and money. Modular parts allow upgrades and changes. You can keep the product safe and reliable by maintaining tolerances and proper fitting.

Steps in the General Assembly Design Process

The process of assembly design is done step by step.

Concept Development – Define the goal and how the parts will join

Component Design – Create and test each part.

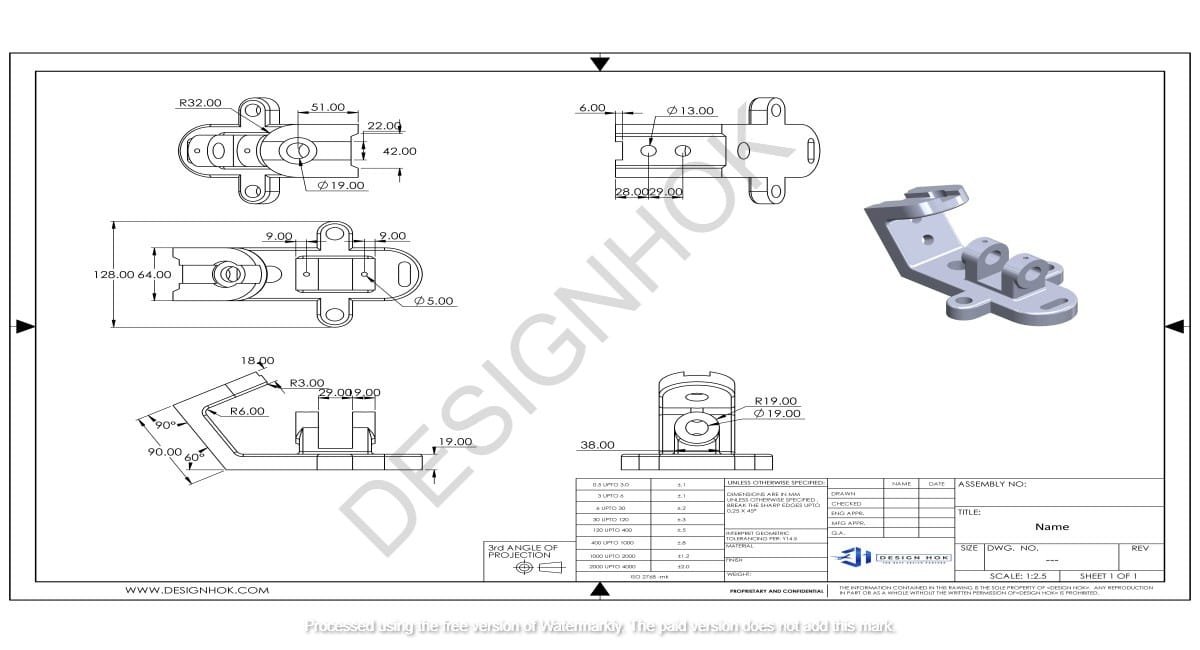

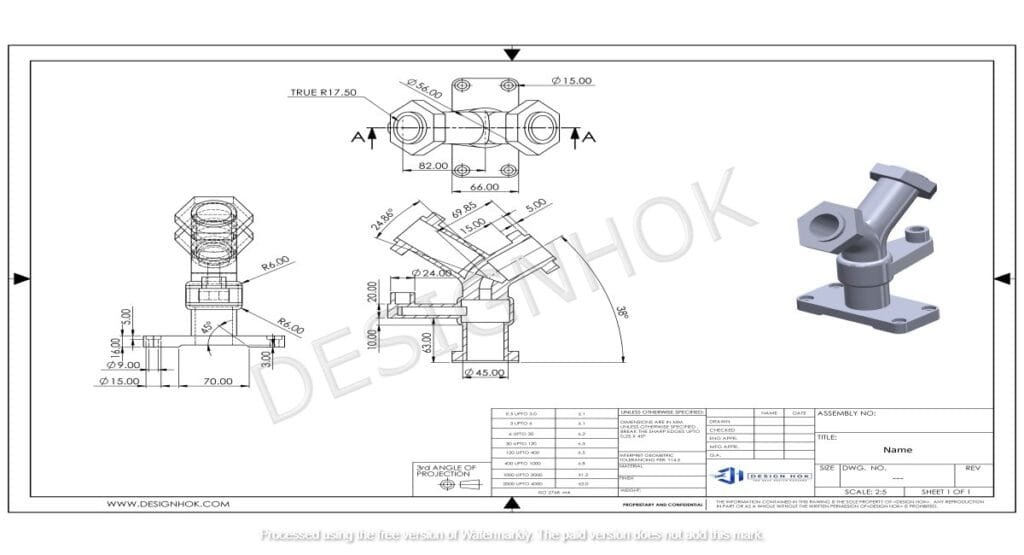

Virtual Assembly – You use CAD software to create a model of how all parts will fit together. You are able to recognize issues before making actual parts.

Tolerance Check – You have to make sure that the parts are made within the right size limits. This helps you to fit together the parts. This helps to avoid parts that are too loose or too tight.

Prototype Assembly – In this step, you create an actual sample of a product. You can check how everything will appear and behave in real life.

Documentation – This involves writing clear assembly instructions to tell how to assemble products. So, workers know exactly where to put everything.

Tools and Technology

Many devices are used by engineers to make this process easier and more accurate. They use software named CAD to make 3D models. FEA checks how parts react to stress and heat. Simulation tools test the assembly before production. Moreover, 3D printing lets you make quick prototypes to test.

Challenges in General Assembly Design

There are some common issues in this process. It can be quite difficult to manage large assemblies. Balancing tolerances is often tricky. You also have to make sure to minimize assembly time. You have to pick those materials that work well with each other for long-term performance.

Applications of General Assembly Design

A number of fields depend on assembly design. It is used in the automotive industry for engines, frames, and inner parts. Small parts can fit into minute spaces using it. Your assembly design makes sure that heavy machines are strong and secure. Various construction projects depend on it to align beams, panels, and structures.

Best Practices

Good assembly design follows clear rules. You can use modular parts for upgrades and repairs. In addition to that, plan the order of assembly to save time. Use standard parts whenever possible. You have to make sure that your design does not put the worker at risk. You have to test samples frequently and make improvements.

Assembly Design in the Coming Decades

In the future, you will notice more automation. Complicated tasks will be done faster and accurately using machines. New tools will help make designs even simpler. Products will be built quickly and with higher quality.

Conclusion

General assembly design is the basis of reliable products. It makes sure all parts work together as one. From early ideas to production, it keeps the process smooth and efficient. With new technology, assembly design will continue to grow and improve industries worldwide.

FAQs

- What is general assembly design?

It is the process of joining parts to make a complete product. - Why is tolerance analysis important in assembly design?

You make sure that the parts fit correctly and work. - List the tools used for general assembly design.

CAD, FEA, simulations, and 3D printing are common tools. - How does modular design help?

You can repair, upgrade, and do part replacements through modular design. - Name the industries using it.

There are a number of fields depending on it. These include automotive, electronics, machinery, and construction.