Description:

Discover the intricate process of designing automated mechanical machines, from conceptualization to implementation. Learn how these innovations optimize operations, boost efficiency, and transform industries.

Introduction

Designing Automated Mechanical Machines are the epitome of modern engineering marvels. By combining mechanical systems with automation technology, these machines have revolutionized industries, enhancing productivity, precision, and reliability. From manufacturing to healthcare, these innovations are integral to advancing operations and achieving new milestones in technology. In this article, we’ll explore the fundamentals of designing automated mechanical machines, including the stages involved, their applications, and the challenges engineers face.

Understanding Designing Automated Mechanical Machines

Automated mechanical machines are systems that operate with minimal human intervention, relying on integrated technologies like robotics, sensors, and software to perform specific tasks. These machines are designed to replicate, enhance, or replace human efforts in various processes. Examples include robotic arms in assembly lines, automated conveyor belts in warehouses, and precision machinery in healthcare.

Key characteristics of automated mechanical machines include:

- Efficiency: Consistent and reliable operation without fatigue.

- Precision: High accuracy, minimizing errors in repetitive tasks.

- Scalability: Adaptable to various applications and industries.

Stages of Designing Automated Mechanical Machines

1. Problem Identification

The design process begins with understanding the problem or task the machine needs to address. This involves a thorough analysis of requirements, existing solutions, and desired outcomes. Engineers collaborate with stakeholders to identify constraints like cost, space, and time.

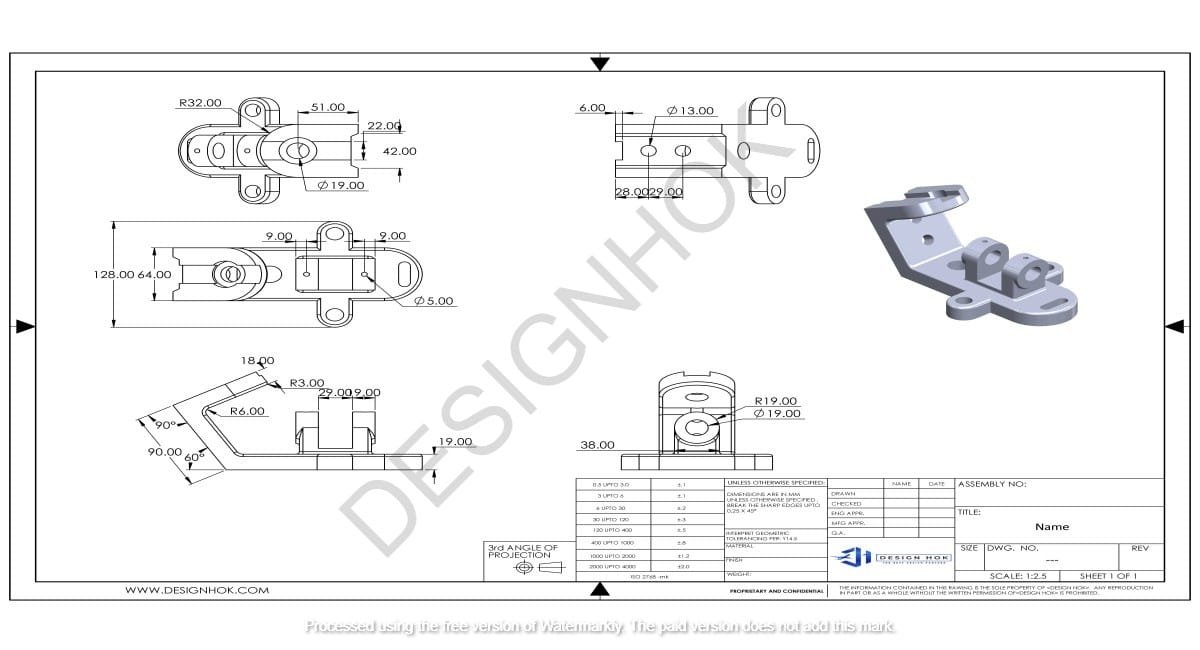

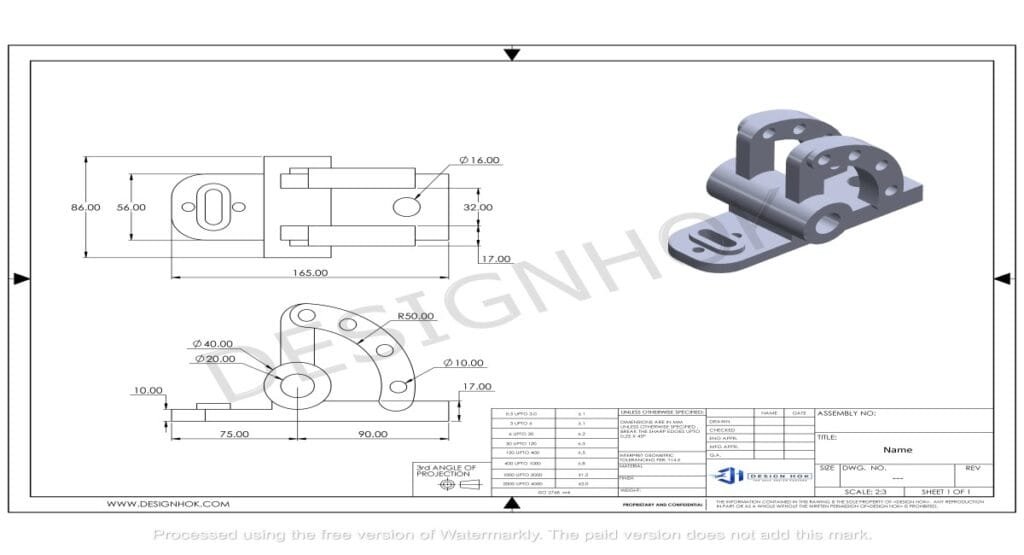

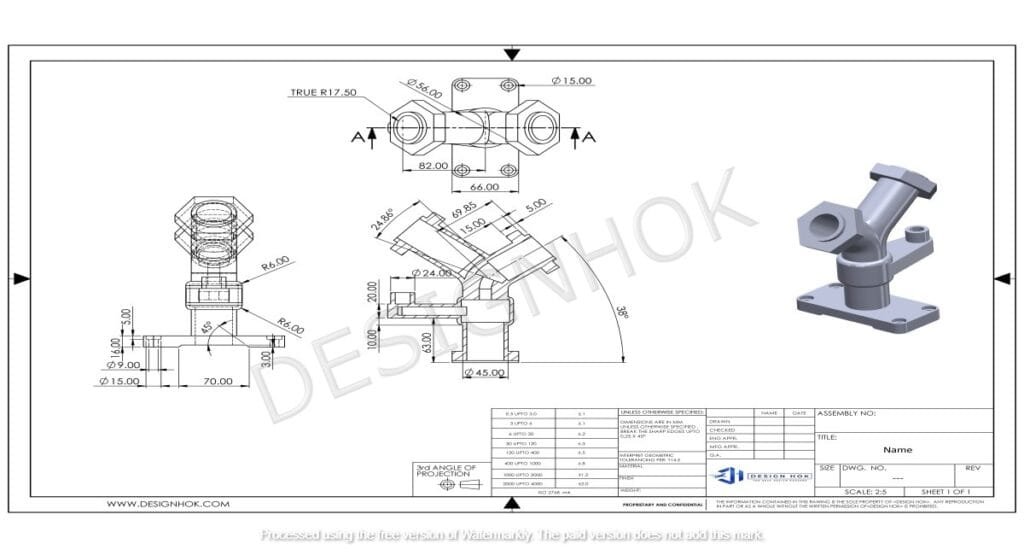

2. Conceptual Design

Once the problem is defined, the conceptual design phase focuses on brainstorming ideas and sketching preliminary models. Engineers use CAD (Computer-Aided Design) software to create detailed 2D and 3D representations of the proposed machine. These designs are analyzed for feasibility and refined to meet the specific requirements.

3. Material Selection

Choosing the right materials is crucial for ensuring the machine’s durability and performance. Factors like weight, strength, corrosion resistance, and cost are considered. For instance, stainless steel might be selected for medical devices, while lightweight alloys are preferred for robotics.

4. Prototyping

Prototyping involves building a functional model of the machine. This phase allows engineers to test the design’s effectiveness and identify potential issues. Prototypes can range from simple physical models to advanced functional units integrated with software systems.

5. Automation Integration

Automation systems are integrated into the mechanical design. This includes:

- Sensors: To detect inputs like pressure, temperature, or position.

- Actuators: For converting energy into motion.

- Control Systems: To manage machine operations using algorithms and software.

This stage ensures seamless interaction between mechanical and electronic components.

6. Testing and Validation

Before deployment, the machine undergoes rigorous testing to validate its performance, safety, and reliability. Engineers simulate various scenarios to ensure the machine meets industry standards and operates effectively under different conditions.

7. Implementation and Maintenance

After successful testing, the machine is implemented in its intended environment. Regular maintenance schedules are established to ensure longevity and optimal performance. Advanced designs may include self-diagnostic features to monitor functionality.

Applications of Designing Automated Mechanical Machines

Automated mechanical machines are transforming various industries:

- Manufacturing: Robotic arms, automated assembly lines, and CNC machines streamline production, improving efficiency and quality.

- Healthcare: Automated surgical devices, lab equipment, and prosthetic systems enhance precision and patient care.

- Logistics and Warehousing: conveyor systems, automated guided vehicles (AGVs), and drones optimize inventory management and transportation.

- Agriculture: Machines like automated harvesters and irrigation systems boost productivity while reducing labor costs.

- Automotive Industry: Robotic systems handle tasks like welding, painting, and assembling vehicle components.

- Aerospace: Automated systems assist in manufacturing complex aircraft components and performing precise inspections.

Challenges in Designing Automated Mechanical Machines

- High Initial Costs: Developing and implementing automated systems can be expensive.

- Complexity: Integrating mechanical and electronic systems requires specialized expertise.

- Maintenance and Upgrades: Advanced machines require regular updates and skilled personnel for maintenance.

- Adaptability: Ensuring the machine can adapt to changing requirements and technologies is a challenge.

- Cybersecurity Risks: Automated systems connected to networks are vulnerable to cyber threats.

Future of Designing Automated Mechanical Machines

The future of automated mechanical machines lies in advancements in artificial intelligence (AI), machine learning, and the Internet of Things (IoT). These technologies will enable machines to learn, adapt, and optimize themselves in real time, reducing the need for human intervention even further. Innovations in sustainable materials and energy-efficient designs will also contribute to creating environmentally friendly automated solutions.

Industries can expect a surge in collaborative robots (cobots), which work alongside humans to enhance productivity. Additionally, modular designs will allow companies to customize machines for specific tasks, reducing costs and increasing versatility.

Conclusion

Designing automated mechanical machines is a multidisciplinary process that combines mechanical engineering, software development, and innovative problem-solving. These machines have become indispensable in various sectors, driving efficiency, precision, and technological progress. While challenges exist, continuous advancements in technology promise a future where automation will redefine the possibilities of mechanical systems. By investing in research and embracing innovation, industries can unlock the full potential of automated mechanical machines, shaping a smarter, more efficient world.

FAQ

1. What is the main purpose of automated mechanical machines?

Automated mechanical machines aim to perform repetitive tasks with high efficiency and precision, reducing human effort and increasing productivity across various industries.

2. What technologies are used in automation?

Automation relies on technologies like sensors, actuators, robotics, control systems, AI, and machine learning to enable seamless operation.

3. How do automated mechanical machines benefit industries?

These machines enhance efficiency, improve accuracy, reduce operational costs, and ensure consistent quality in manufacturing, healthcare, logistics, and more.

4. What challenges are associated with designing automated machines?

Challenges include high development costs, system complexity, maintenance requirements, and ensuring adaptability to changing technologies.

5. What is the future of automated mechanical machines?

The future lies in integrating AI, IoT, and sustainable practices, leading to smarter, adaptive, and environmentally friendly automated solutions.

6. Are automated machines replacing human workers?

Automated machines often complement human workers by taking over repetitive and dangerous tasks, allowing humans to focus on creative and strategic roles.