Description

DesignHOK CAD Services with AS 9100 Standards, ensuring unmatched quality, precision, and compliance in aerospace and defense projects. This guide explores how DesignHOK integrates CAD expertise with AS 9100 requirements to offer scalable, compliant, and future-ready engineering solutions.

1. Introduction to DesignHOK CAD Services

DesignHOK CAD Services with AS 9100 Standards is a leading provider of Computer-Aided Design (CAD) services, specializing in mechanical, aerospace, and industrial design. With a reputation for delivering high-precision models, 2D drafting, 3D modeling, and mechanical design documentation, DesignHOK serves a broad client base—from startups to Fortune 500 companies.

To stand out in regulated industries like aerospace and defense, DesignHOK follows the stringent AS 9100 standards, ensuring that every CAD deliverable meets aerospace-grade quality expectations.

2. Understanding DesignHOK CAD Services with AS 9100 Standards in Aerospace

AS 9100 is the global Quality Management System (QMS) standard specifically for the aerospace, space, and defense industries. Developed by the International Aerospace Quality Group (IAQG), it expands upon ISO 9001 and includes additional clauses for DesignHOK CAD Services with AS 9100 Standards focusing on:

- Product safety and traceability

- Risk-based thinking

- Configuration and change management

- Supplier quality control

- Non-conformance tracking and resolution

NLP Phrases:

- aerospace design compliance

- CAD solutions under AS 9100

- certified aerospace design workflows

3. Why AS 9100 Matters in CAD Design

In sectors where failure is not an option, CAD designs must not only be accurate but also fully traceable and compliant. Integrating AS 9100 standards into CAD workflows means that:

- Designs adhere to verified requirements

- Every design iteration is documented

- Risks are assessed and mitigated

- There is a clear chain of custody and revision control

This is especially vital for parts that go into aircraft, spacecraft, satellites, and defense systems.

4. Key Features of DesignHOK CAD Services

DesignHOK offers a wide range of CAD capabilities tailored for high-risk, precision-focused industries:

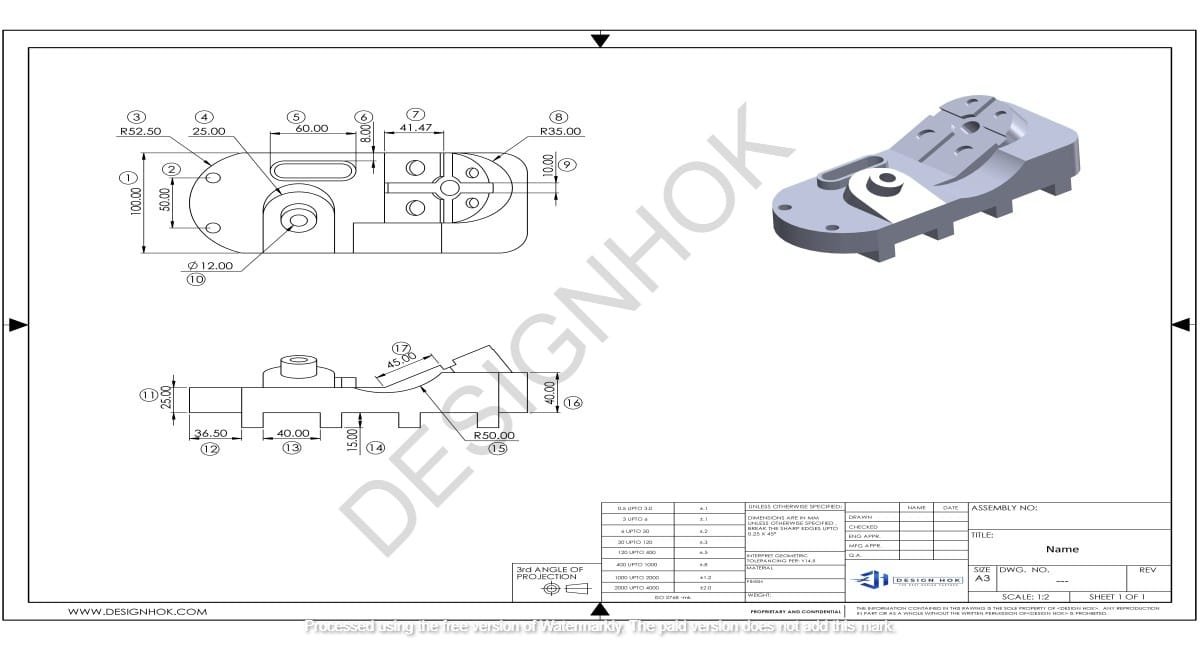

✅ 2D & 3D CAD Drafting

From concept sketches to manufacturing-ready drawings.

✅ Mechanical Design Engineering

Complete design of assemblies, mechanisms, and enclosures.

✅ 3D Modeling & Rendering

Solid modeling, surface modeling, and photorealistic renderings.

✅ Assembly & Manufacturing Drawings

Exploded views, BOMs (Bill of Materials), and tolerancing per GD&T standards.

✅ Design for Manufacturing (DFM)

Optimizing CAD models to reduce cost and increase manufacturability.

Each of these services is performed under documented procedures to meet AS 9100 compliance criteria.

5. Integration of DesignHOK CAD Services with AS 9100 Standards Workflow

DesignHOK’s unique value lies in how deeply integrated AS 9100 protocols are within its design process:

| Phase | AS 9100 Aligned Action |

|---|---|

| Project Onboarding | Define project scope, risks, and quality goals |

| CAD Execution | Apply validated design processes with revision control |

| Quality Review | Conduct peer and senior-level audits |

| Client Approval | Use documented verification and traceability methods |

| Post-Delivery Support | Archive records and manage non-conformance issues if any |

6. Quality Assurance Through CAD + AS 9100

DesignHOK CAD Services with AS 9100 Standards-compliant processes, DesignHOK ensures:

- Zero Defect Mindset: All models are tested for functionality and manufacturability.

- Traceability: Every drawing and 3D model is versioned and logged.

- Client Verification: Files are reviewed against project requirements and applicable standards.

- Document Control: All drawings are released through a configuration-managed environment.

These practices significantly reduce downstream issues during manufacturing, assembly, or quality control.

7. Industries That Benefit from DesignHOK’s AS 9100-Compliant CAD

✈️ Aerospace & Aviation

DesignHOK CAD Services with AS 9100 Standards For aircraft interiors, turbines, and control mechanisms, every detail must meet FAA and EASA regulations. DesignHOK helps ensure those requirements are embedded from the CAD level.

🛡️ Defense & Security

Military-grade components require rugged, traceable, and fault-tolerant designs. AS 9100 ensures compliance for mission-critical applications.

🚀 Space Systems

Satellites, propulsion systems, and structural elements demand high-fidelity design and documentation, which DesignHOK offers through its AS 9100-aligned methodology.

⚙️ Advanced Manufacturing

For CNC machining, additive manufacturing, and precision tooling, DesignHOK provides CAD files that are manufacturing-ready and traceable.

8. Competitive Advantages for Manufacturers and Engineers

Choosing DesignHOK for your CAD needs delivers measurable business value:

- Faster Project Turnaround: Streamlined processes and risk management.

- Regulatory Confidence: Designs meet AS 9100 clauses for audit readiness.

- Improved Supplier Trust: Demonstrated design control and traceability.

- Better Manufacturing Outcomes: DFM and quality checks minimize errors and rework.

- Global Market Access: Certification-ready documentation improves supply chain approval.

9. Getting Started with DesignHOK

If you’re looking to integrate CAD services into your aerospace or defense workflow with full AS 9100 compliance, DesignHOK offers flexible project engagement models, including:

- Hourly CAD support

- Project-based mechanical design

- Ongoing CAD documentation and revision management

- Turnkey engineering with compliance documentation

Reach out to DesignHOK to discuss your specifications, and get a compliance-ready CAD solution tailored for your business.

10. Frequently Asked Questions (FAQ)

Q1: What makes DesignHOK’s CAD services AS 9100 compliant?

DesignHOK follows documented procedures in line with AS 9100, ensuring traceability, risk control, design verification, and non-conformance management across all projects.

Q2: Is AS 9100 certification required for CAD services?

While it’s not legally required, AS 9100 compliance is often a contractual necessity in aerospace and defense sectors. DesignHOK CAD Services with AS 9100 Standards ensures your CAD partner understands and adheres to quality-critical protocols.

Q3: How does AS 9100 improve CAD quality?

It introduces rigorous process control, risk mitigation, and review cycles, ensuring every CAD file meets the highest standards of accuracy, safety, and usability.

Q4: Can DesignHOK handle defense or classified projects?

Yes. DesignHOK CAD Services with AS 9100 Standards has the infrastructure and discipline required for handling sensitive, defense-related design tasks under strict quality and security protocols.

Q5: How do I start a project with DesignHOK?

Simply contact the DesignHOK team with your project scope, objectives, and compliance requirements. You’ll receive a tailored quote and a roadmap to completion with AS 9100 assurance.

Final Thoughts

DesignHOK CAD Services with AS 9100 Standards bridges the gap between creative engineering and aerospace-grade compliance. By embedding AS 9100 principles into every CAD workflow, DesignHOK ensures its clients receive certification-ready designs, improved reliability, and fewer production delays. Whether you’re building an aircraft system, military component, or satellite sub-assembly, you can trust DesignHOK to deliver quality you can count on—by design.