Description

Machine design is a cornerstone of mechanical engineering, merging scientific principles with creative problem-solving to develop efficient and reliable mechanical systems. This comprehensive guide delves into the essential elements, techniques, and applications of machine design, showcasing its pivotal role in modern industries.

Introduction

Design in Mechanical Engineering is a sophisticated blend of science, engineering principles, creativity, and precision. It involves conceptualizing, designing, and optimizing machines that serve specific purposes, whether in manufacturing, transportation, energy production, or other industries. A well-designed machine not only performs its intended function effectively but also ensures durability, safety, and cost-efficiency.

the fundamental aspects of machine design, the methodologies employed, and its practical applications, shedding light on why this discipline remains a crucial facet of mechanical engineering.

What is Design in Mechanical Engineering?

Machine design is the systematic process of transforming ideas into functional mechanical systems. It encompasses the following steps:

- Problem Definition: Identifying the need or problem the machine will address.

- Conceptual Design: Brainstorming possible solutions and creating initial sketches or CAD models.

- Detailed Design: Refining the chosen concept with precise dimensions, material selection, and component integration.

- Prototyping and Testing: Developing a working prototype and testing it under real-world conditions.

- Finalization and Production: Implementing feedback from testing to create a finalized design for mass production.

Key Principles of Design in Mechanical Engineering

Machine design follows a set of guiding principles to ensure functionality, safety, and efficiency:

- Strength and Durability: Materials and components must withstand applied forces without failure over the machine’s expected lifespan.

- Simplicity: The design should minimize complexity to reduce manufacturing costs and improve reliability.

- Economy: Cost-effective material selection and manufacturing processes are essential.

- Functionality: The design must meet all operational requirements.

- Safety: Incorporating safeguards to protect operators and ensure compliance with safety standards.

Types of Design in Mechanical Engineering

Design in Mechanical Engineering can be classified into several types based on the purpose and complexity of the machine:

- Adaptive Design: Modifying existing designs to suit new requirements, such as customizing a conveyor belt for different industries.

- Developmental Design: Improving an existing design to enhance performance, such as creating a more fuel-efficient engine.

- New Design: Creating entirely new machines, such as robotic arms for automated assembly lines.

Tools and Techniques in Design in Mechanical Engineering

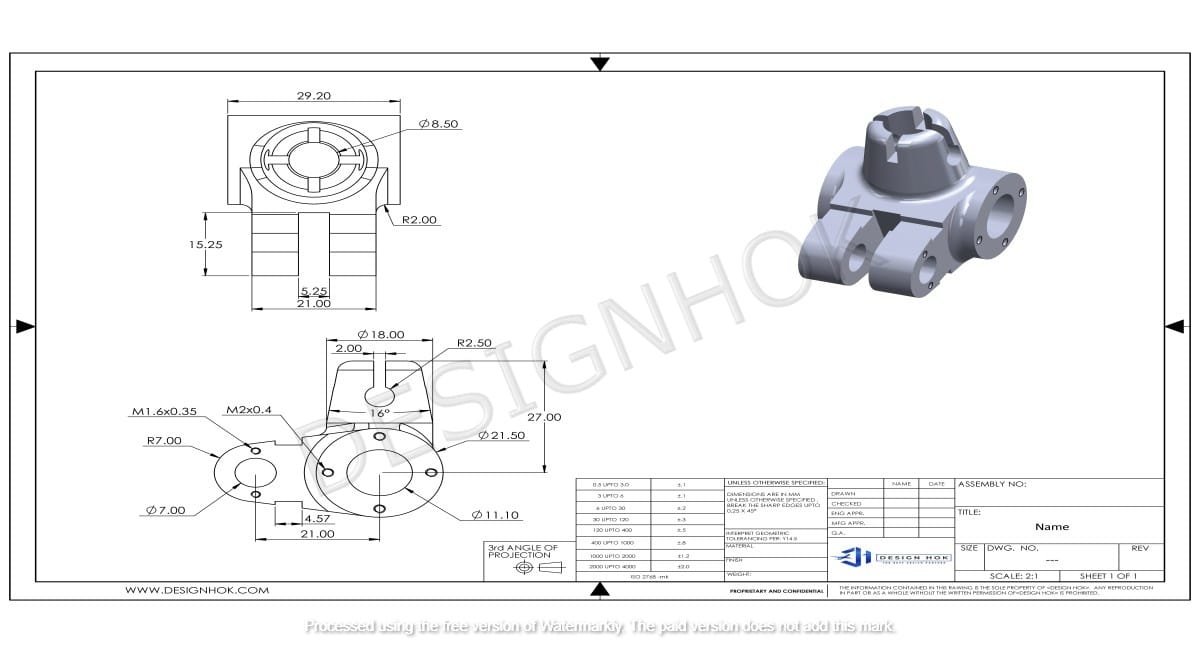

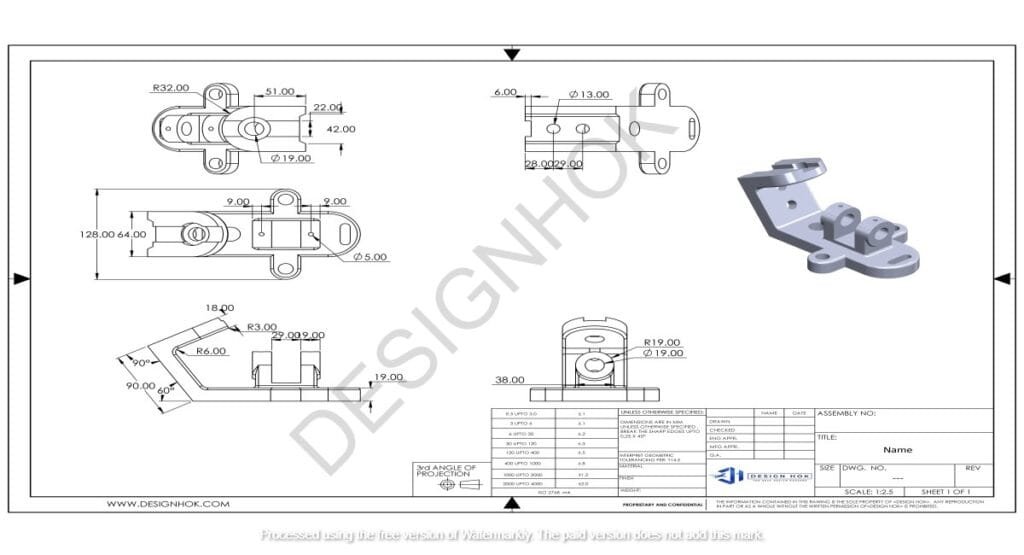

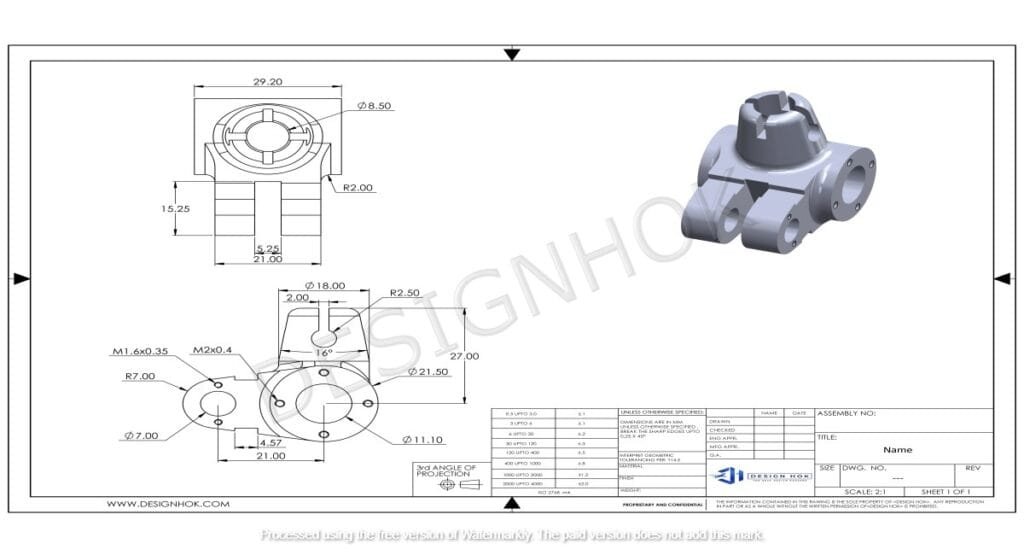

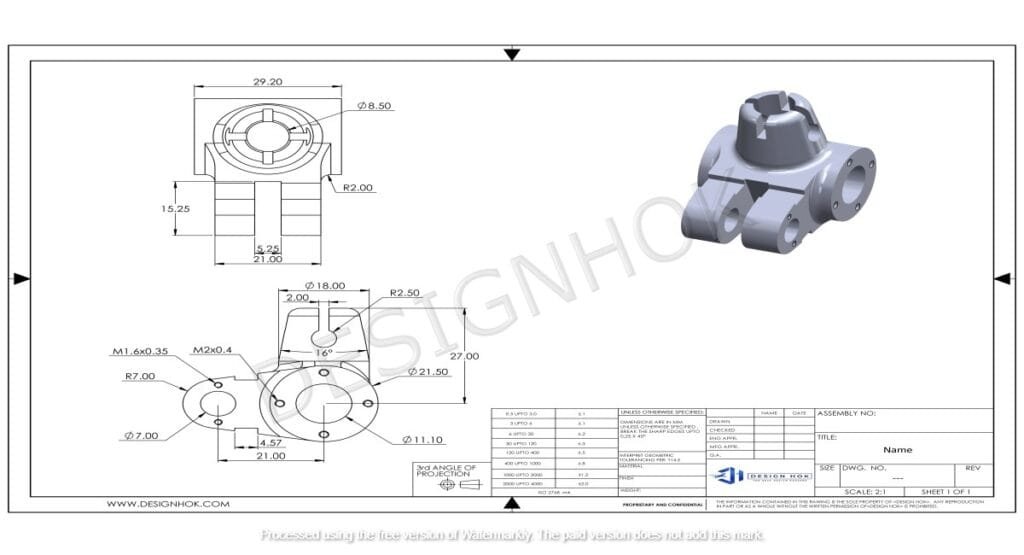

- CAD Software: Programs like AutoCAD, SolidWorks, and CATIA allow engineers to create detailed 2D and 3D models.

- Finite Element Analysis (FEA): Simulates physical forces and stresses on the design to identify weaknesses.

- Material Selection Tools: Databases like CES Selector assist in choosing the right materials for the design.

- Prototyping Methods: Additive manufacturing (3D printing) and traditional machining enable the creation of test models.

Applications of Design in Mechanical Engineering

Machine design is integral to countless industries. Some notable applications include:

- Automotive Engineering: Designing engines, transmissions, and safety systems for vehicles.

- Aerospace: Developing lightweight, durable components for aircraft and spacecraft.

- Manufacturing: Creating assembly line machinery, cutting tools, and robotics.

- Energy Sector: Designing turbines, generators, and pumps for energy production.

- Medical Devices: Innovating precise and reliable equipment for healthcare, such as MRI machines and prosthetic devices.

Challenges in Machine Design

Despite its importance, machine design comes with several challenges:

- Material Limitations: Finding materials that meet strength, weight, and cost criteria can be difficult.

- Complex Requirements: Balancing functionality with safety, durability, and economic constraints.

- Technological Advances: Keeping up with rapid technological changes to incorporate the latest innovations.

- Sustainability: Designing eco-friendly machines with minimal environmental impact.

Future Trends in Design in Mechanical Engineering

As industries evolve, machine design is increasingly influenced by emerging trends:

- Automation: Incorporating artificial intelligence (AI) and machine learning for smarter, autonomous machines.

- Sustainability: Designing energy-efficient machines and using recyclable materials.

- Additive Manufacturing: Leveraging 3D printing for complex, lightweight designs.

- Digital Twins: Using virtual models to predict performance and optimize designs before physical production.

Conclusion

Design in Mechanical Engineering is a dynamic field that lies at the intersection of creativity and practicality. By blending innovative ideas with scientific principles, it enables the development of machines that drive progress across industries. Whether it’s improving efficiency in a factory or advancing technologies in space exploration, machine design remains an indispensable part of engineering.

As technology continues to evolve, the principles of machine design will adapt, paving the way for more sophisticated, sustainable, and intelligent machines.

FAQs

1. What is the primary purpose of machine design?

The primary purpose of machine design is to create mechanical systems that fulfill specific functions efficiently, safely, and cost-effectively while meeting durability and performance criteria.

2. What role does material selection play in machine design?

Material selection is crucial in machine design as it determines the strength, weight, durability, and cost of the machine. Engineers must balance these factors to achieve the desired performance.

3. How does CAD software assist in machine design?

CAD software allows engineers to create detailed 2D and 3D models, visualize designs, and perform simulations to test the feasibility and performance of the design before production.

4. What are some common challenges in machine design?

Common challenges include selecting suitable materials, balancing complex requirements, keeping up with technological advancements, and designing sustainable and eco-friendly machines.

5. Why is prototyping essential in machine design?

Prototyping helps validate the design, identify potential issues, and refine the final product based on real-world testing.

6. How is machine design evolving with technology?

Machine design is evolving with advancements in automation, AI, additive manufacturing, and sustainability, leading to smarter, more efficient, and environmentally friendly designs.