Description

Custom Mechanical Design under AS 9100 – DesignHOK provides fully compliant custom mechanical design services under the AS 9100 standard, ensuring aerospace-grade quality and precision. This guide explains how Custom Mechanical Design under AS 9100 – DesignHOK integrates with mechanical engineering practices at Design HOK, ensuring safety, innovation, and regulatory excellence for every design solution.

Table of Contents

- Introduction to Custom Mechanical Design

- Why AS 9100 Certification Matters

- Design HOK’s Commitment to AS 9100

- Core Components of Custom Mechanical Design Under AS 9100

- Client-Centric Requirements

- Risk-Based Design Philosophy

- Material and Process Traceability

- Design Verification and Validation

- Design for Manufacturability (DFM)

- Tools and Technologies Used by Design HOK

- Industries Served with AS 9100 Compliant Designs

- Benefits of Choosing Design HOK

- Steps in the AS 9100 Design Lifecycle at Design HOK

- Challenges in AS 9100 Mechanical Design and Our Solutions

- Conclusion

- FAQ

1. Introduction to Custom Mechanical Design under AS 9100 – DesignHOK

Custom Mechanical Design under AS 9100 – DesignHOK involves the development of engineered systems, parts, or assemblies tailored to specific functional and environmental requirements. Whether it’s high-load components for aerospace or precision housings for electronic systems, design accuracy and reliability are crucial.

At Design HOK, we merge creativity with engineering excellence, following the strict requirements of AS 9100, the international aerospace quality management standard.

2. Why Custom Mechanical Design under AS 9100 – DesignHOK Certification Matters

AS 9100 is more than a certificate—it’s a rigorous framework ensuring that every phase of design and production meets the highest quality, safety, and traceability standards.

Benefits of AS 9100 in Design

- Ensures risk mitigation and product safety

- Aligns with aerospace customer expectations

- Mandates detailed documentation and verification

- Elevates confidence among clients and stakeholders

- Essential for bidding in aerospace and defense contracts

By integrating AS 9100 into our workflows, Design HOK provides reliable, audit-ready, and performance-driven solutions.

3. Design HOK’s Commitment to AS 9100

Custom Mechanical Design under AS 9100 – DesignHOK has built its engineering culture around the core values of AS 9100: precision, reliability, safety, and continuous improvement. Our internal QMS (Quality Management System) is structured to:

- Capture customer-specific requirements

- Enforce quality from concept to prototype

- Ensure total traceability of components and processes

- Conduct regular design reviews and internal audits

With AS 9100 at the heart of operations, every mechanical design meets global aerospace standards.

4. Core Components of Custom Mechanical Design under AS 9100 – DesignHOK

✅ Client-Centric Requirements

AS 9100 begins with capturing clear customer requirements, including performance specs, environmental constraints, regulatory needs, and safety margins. Design HOK engineers conduct:

- Requirement analysis sessions

- Feasibility assessments

- Compliance mapping to industry codes (e.g., MIL-STD, FAA)

✅ Risk-Based Design Philosophy

Every design process is built around risk identification and mitigation. Our design engineers perform:

- Failure Mode and Effects Analysis (FMEA)

- Hazard analysis for mission-critical systems

- Redundancy and fail-safe mechanism planning

✅ Material and Process Traceability

Material selection is tracked and verified. We maintain:

- Supplier qualification records

- Batch-level documentation

- Certificates of conformance and material testing

This traceability is vital for regulatory audits and product recalls.

✅ Design Verification and Validation

We follow a structured V&V protocol to test design integrity:

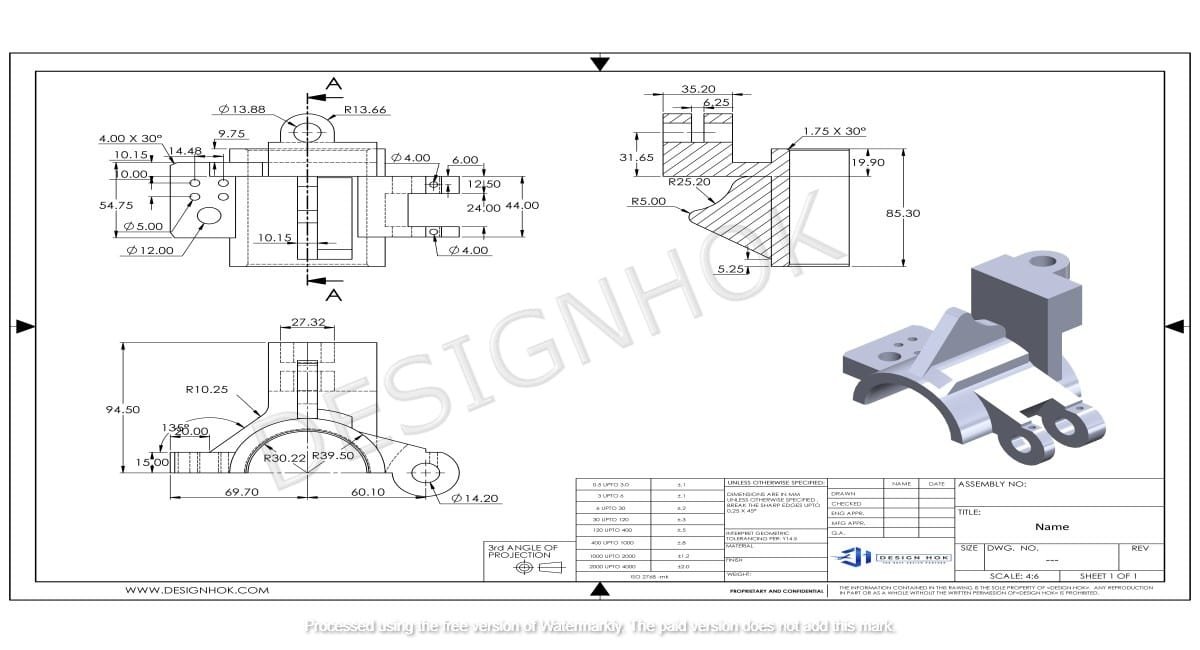

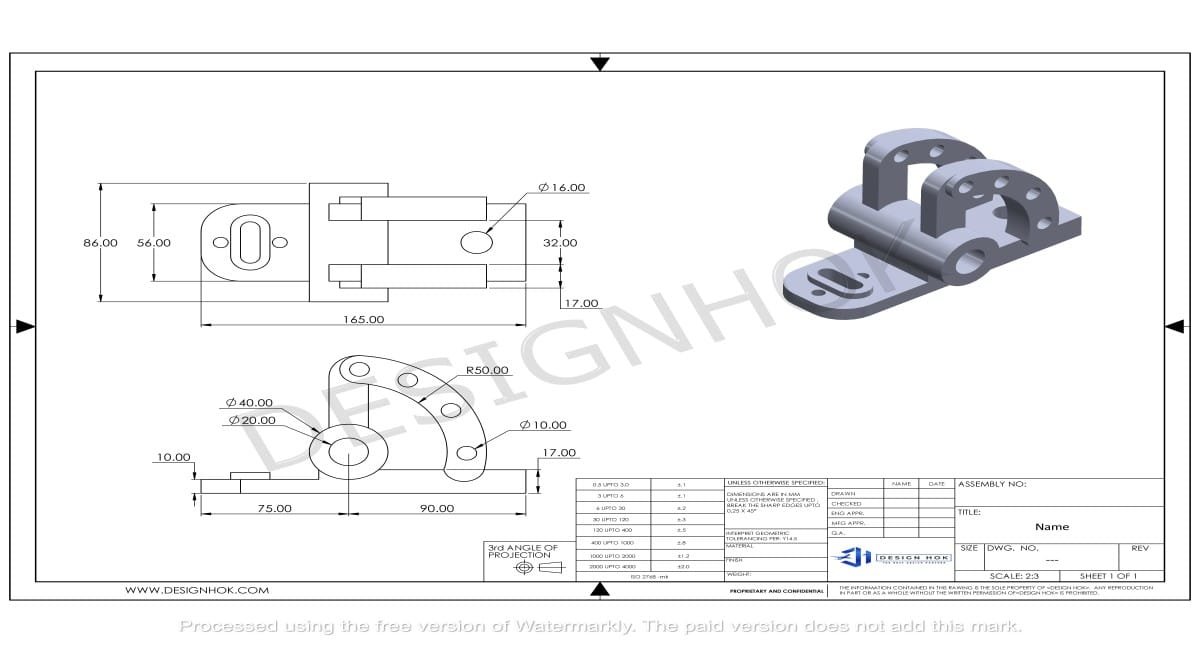

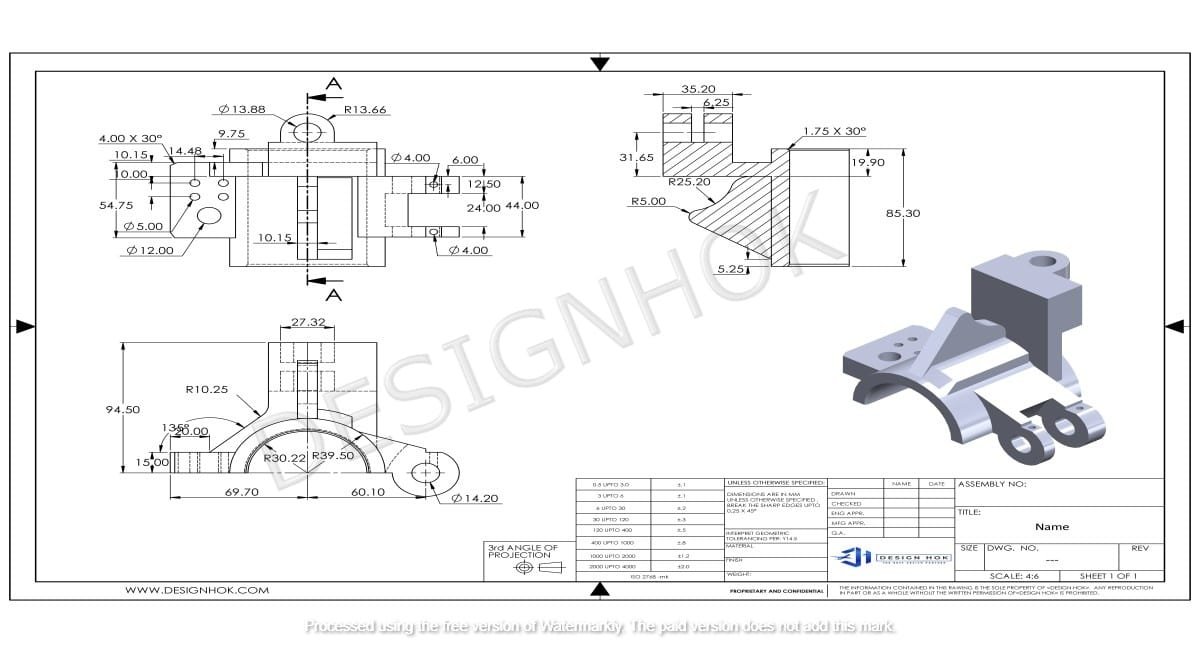

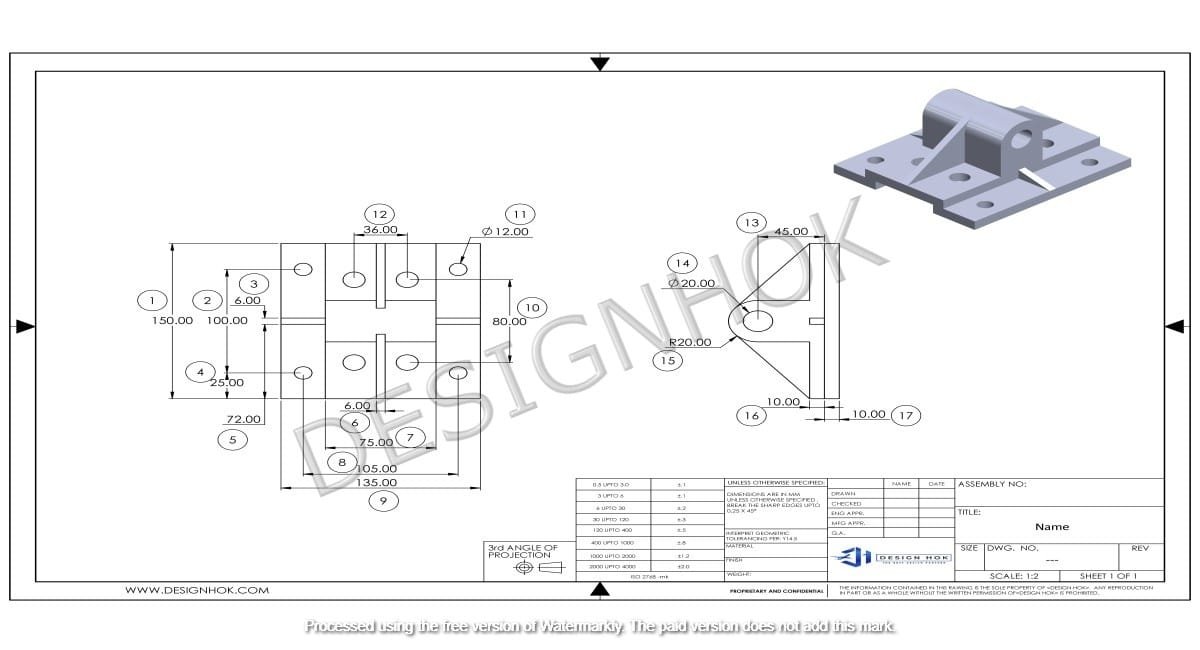

- CAD simulations and thermal stress analysis

- Prototype testing in controlled environments

- User requirement validation and field performance testing

✅ Design for Manufacturability (DFM)

Design HOK emphasizes manufacturability from day one. We ensure:

- Tolerances and geometries match production capabilities

- Tooling and fixtures are optimized

- Assembly processes are error-proofed

This minimizes production costs and lead times.

5. Tools and Technologies Used by Design HOK

Our AS 9100-compliant design process is backed by cutting-edge tools:

- CAD/CAE Tools: SolidWorks, CATIA, Creo

- Simulation Software: ANSYS, MATLAB, Autodesk CFD

- PLM Systems: Siemens Teamcenter, PTC Windchill

- Document Control: ISO-compliant cloud systems with version control

- Real-Time Collaboration Tools: Autodesk Fusion 360, Onshape

These platforms support traceability, data integrity, and audit readiness.

6. Industries Served with AS 9100 Compliant Designs

Design HOK provides compliant mechanical designs for a variety of sectors:

- Aerospace & Defense: Aircraft structures, drone housings, missile subsystems

- Aviation MROs: Custom tools, testing jigs, and retrofits

- Space Systems: Lightweight brackets, satellite components

- Medical Devices: Aerospace-level quality applied to mission-critical instruments

- Industrial Equipment: Heavy-duty custom parts for harsh environments

7. Benefits of Choosing Design HOK

Partnering with Custom Mechanical Design under AS 9100 – DesignHOK ensures:

- Risk-free design development

- Faster time-to-certification for aerospace approvals

- Transparent design history and revision tracking

- Interdisciplinary collaboration with manufacturing and QA

- Adaptability to client-specific standards and goals

Each project is built to function, last, and pass scrutiny from both customers and regulatory bodies.

8. Steps in the AS 9100 Design Lifecycle at Design HOK

Here’s how we align our custom design projects with AS 9100 standards:

- Requirement Gathering

- Concept Design with DFM and safety considerations

- Risk Analysis and Material Selection

- Simulation & Prototyping

- Validation Testing & Review

- Design Release with Documented Traceability

- Customer Feedback & Continuous Improvement

Each phase is documented and version-controlled, making the entire process transparent and audit-ready.

9. Challenges in Custom Mechanical Design under AS 9100 – DesignHOK and Our Solutions

Challenge 1: Meeting Changing Compliance Requirements

Solution: Our QA team continuously monitors IAQG updates and updates internal processes accordingly.

Challenge 2: Balancing Innovation with Certification

Solution: Innovation is driven by validated simulations and prototyping before release.

Challenge 3: Cross-team Miscommunication

Solution: We implement project portals and PLM systems for real-time updates and interdepartmental clarity.

10. Conclusion

Custom Mechanical Design under AS 9100 – DesignHOK is not just about technical drawings—it’s about ensuring safety, functionality, traceability, and compliance at every level. At Design HOK, we fuse precision engineering with aerospace-grade quality standards to deliver designs that meet and exceed the toughest industry expectations.

With a proven record in delivering AS 9100-compliant projects, our approach empowers businesses in aerospace, defense, and beyond to innovate confidently and launch products that meet global regulatory expectations.

11. Frequently Asked Questions (FAQ)

Q1. What is AS 9100 and why is it important for mechanical design?

AS 9100 is an aerospace quality standard ensuring that mechanical designs meet strict requirements for safety, traceability, and performance. It’s essential for manufacturers supplying to aerospace and defense sectors.

Q2. How does Design HOK ensure AS 9100 compliance?

Design HOK follows a documented, process-driven approach using QMS, verified tools, internal audits, risk analysis, and simulation-based validation aligned with AS 9100 requirements.

Q3. Can I request a customized mechanical design for space or defense use?

Yes, Design HOK specializes in custom mechanical designs for space, defense, and aviation, tailored to meet project-specific and regulatory requirements under AS 9100.

Q4. What industries can benefit from AS 9100-compliant designs?

Industries like aerospace, aviation, space tech, defense, medical, and heavy industrial sectors benefit from AS 9100-grade quality and compliance.

Q5. What tools do you use to develop compliant mechanical designs?

We use SolidWorks, ANSYS, CATIA, PTC Windchill, and cloud-based document control systems to maintain compliance and design accuracy.

Q6. How long does a custom mechanical design project take at Design HOK?

Depending on complexity, timelines vary from 4 to 12 weeks, with milestones clearly mapped and monitored through Gantt charts and client portals.

Q7. Is AS 9100 certification only for large companies?

No. Any manufacturer or design service provider aiming to enter or grow in the aerospace supply chain can benefit from AS 9100 certification, regardless of company size.