Component mechanical design services lie in designing, testing, and improving mechanical parts and components. These services employ modern tools and expert knowledge to ensure that all components work properly, last longer, and meet the necessary standards. Companies are aided in creating better products with the help of smart and practical design solutions offered by them.

In today’s fast-moving industrial world, companies always look for new ways to grow and stay ahead of their competitors. A big part of this growth depends on developing mechanical components that are strong, efficient, affordable, and reliable. Component mechanical design services play an important role in this process. They provide skilled support to turn ideas into real products and also help improve existing designs for better performance and cost savings.

Why Choose Component Mechanical Design Services?

Component mechanical design services encompass the process of designing, analyzing, and enhancing mechanical components. These services are provided by qualified engineers and designers who understand mechanical systems and use specialized tools to create and test components.

This work can be done by designing a single part or creating a complete assembly of parts. The primary aim is to ensure that all component mechanical design services function correctly, meet the required requirements, and accurately match the final product.

Why are these services important?

- Qualified experts and new ideas

Creating mechanical parts requires both creativity and technical knowledge, not just drawing shapes. Mechanical design service companies use CAD software and simulation programs to produce durable and affordable parts. Their experts are constantly researching new technologies and industry trends to create projects that are modern and relevant. Design HOK’s Component mechanical design services can help to create a precise design that follows all the standards.

- Save time and money

It takes a lot of time and meticulous planning to launch a new product. Companies can hire outside resources to perform mechanical design tasks to save time and focus on their core business. The ability of professional designers to reduce development time can result in working more efficiently and quickly. Using Design HOK can result in long-term savings, which can be achieved through reducing material waste and production costs.

- Risk mitigation

Mechanical parts can fail due to stress, pressure, or poor-quality materials. Design service providers thoroughly test and analyze component mechanical design services before starting production. Advanced tools can help you anticipate and resolve potential problems quickly. This can be utilized to prevent costly errors and product failures in the future.

- Personalized solutions for every need

Each industry has different requirements, and off-the-shelf parts aren’t always a perfect fit. Custom mechanical design services create parts that meet the needs of your specific project. Whether for aerospace, medical, or industrial applications, component mechanical design services can tailor their designs to meet your exact requirements.

- Respect for the environment and compliance with laws and regulations

Environmental regulations and industry standards must be followed by today’s businesses. Mechanical design services can help create parts that require less material, save energy, and are easier to recycle. Legal and safety regulations are adhered to by all designs to prevent any future problems.

Mechanical design process

The design of component mechanical design services involves several important stages.

Analysis required:

First, the designer understands what the component mechanical design services need to do. The evaluation involves verifying its performance, the loads it carries, the working environment, and the materials it can be utilized with.

Concept design:

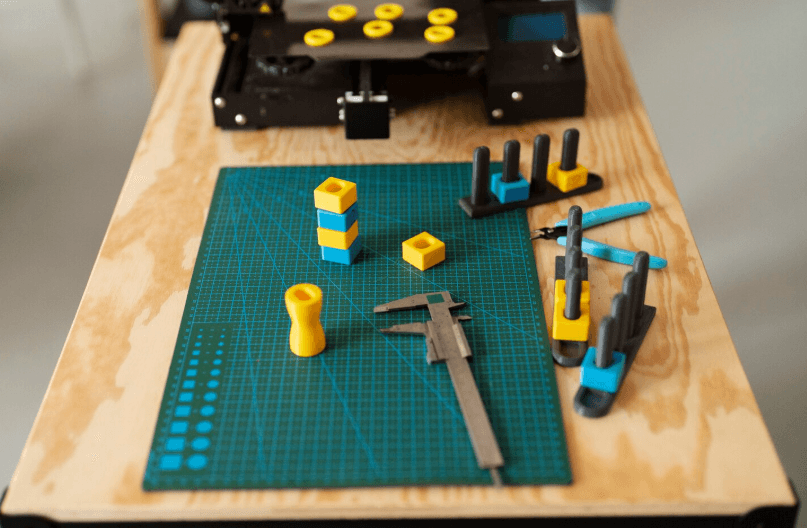

At this point, different design ideas are generated. To identify the best solution, designers can create simple sketches or basic CAD models.

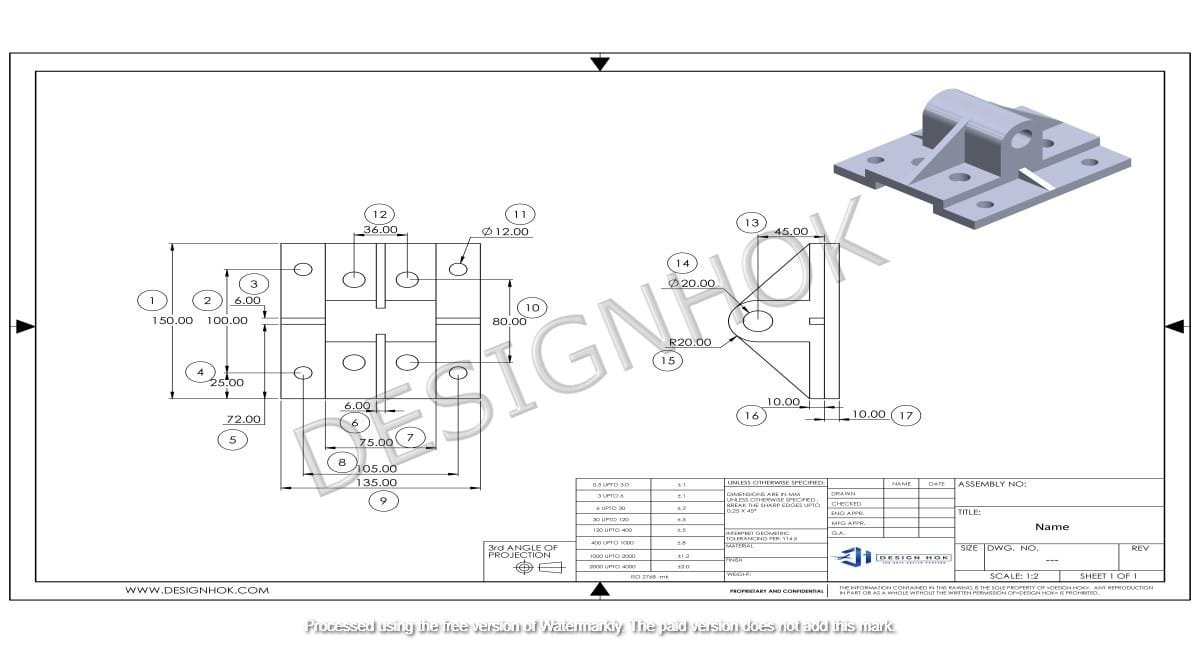

Detailed design:

The design is finalized in detail after selecting the best idea. Exact dimensions, materials, tolerances, and surface finishes are determined and added to the CAD model.

Simulation and testing:

Test your design using computer tools like FEA to see how it performs under different conditions. This allows you to identify and address weaknesses before creating the final product.

The use of real-world conditions in manufacturing and testing a physical model (prototype) ensures it is functional and meets all requirements.

Reviews and documentation:

All drawings, material details, and manufacturing instructions must be prepared to ensure component manufacturing accuracy.

Conclusion

If businesses want to create better products, save money, and launch products faster, mechanical design services are necessary. Companies can ensure that their mechanical parts function properly, last longer, and are environmentally friendly by employing experienced designers. Professional mechanical design services can make all the difference in the world, whether your company is building a new product or improving an old one. These help businesses grow and compete in today’s market.

- Can you explain Mechanical Component Design Services?

These services focus on the design and improvement of mechanical parts and assemblies. To ensure proper function, strength, and longevity, engineers use state-of-the-art software and tools.

- Why should I use mechanical design services?

Hiring a mechanical design expert gives you access to qualified engineers and state-of-the-art tools. This helps create better, more efficient, and more profitable products.

- Which industries use mechanical design services?

These services are used across many industries, including aerospace, automotive, medical devices, electronics, and manufacturing. They rely on mechanical engineering to improve the quality and performance of their products.

- What is the typical mechanical design process?

Understanding the requirements is usually the initial step in the process. After developing design ideas, creating detailed drawings, testing the design through simulation, creating prototypes, and preparing necessary documentation, engineers are ready to proceed.

- How do these services support sustainability?

Mechanical design services can assist in the creation of products that utilize less material, conserve energy, and comply with environmental regulations. This leads to businesses being able to achieve sustainability goals by reducing waste.