Description:

Explore how Benefits of 3D Modeling for Industrial Designers with precision, creativity, and efficiency. This in-depth guide reveals the major advantages of Benefits of 3D Modeling for Industrial Designers and how it shapes the future of product development.

Introduction

Industrial design is the creative engine behind the physical products we use every day — from smartphones and kitchen appliances to automotive components and furniture. As industries evolve, so do the tools that designers use to bring their ideas to life. One of the most transformative tools in modern industrial design is 3D modeling.

Benefits of 3D Modeling for Industrial Designers allows designers to create, manipulate, and visualize objects in a digital space before they are physically produced. This not only enhances the efficiency of the design process but also elevates the quality and accuracy of the final product. For companies and creative studios like DesignHok, Benefits of 3D Modeling for Industrial Designers forms the core of a streamlined, high-quality industrial design workflow.

In this blog, we’ll dive deep into the Benefits of 3D Modeling for Industrial Designers, highlighting how it improves creativity, reduces production costs, enhances collaboration, and brings concepts to life with unmatched precision.

1. Enhanced Visualization and Concept Clarity

One of the biggest challenges in industrial design is communicating ideas clearly — especially to clients, manufacturers, and stakeholders. Benefits of 3D Modeling for Industrial Designers solves this problem by offering realistic, interactive representations of designs.

Instead of rough 2D sketches or abstract drawings, designers can present detailed digital models that can be rotated, zoomed, and examined from every angle. This helps everyone involved understand the product’s form, structure, and function.

For industrial designers, it becomes easier to:

- Showcase design intent

- Identify potential issues early

- Make confident design decisions

DesignHok uses Benefits of 3D Modeling for Industrial Designers as part of client presentations, product pitches, and prototyping workflows, ensuring clarity and alignment across all project stages.

2. Faster and Smarter Iteration

Design is an iterative process. Without the right tools, making changes to a design can be time-consuming and expensive. Benefits of 3D Modeling for Industrial Designers accelerates iteration by allowing designers to edit, test, and update digital prototypes quickly.

Instead of starting from scratch, designers can:

- Modify dimensions with a few clicks

- Swap components easily

- Apply new textures or materials instantly

- Simulate real-world performance (with integrated tools)

This speed enables designers to test multiple design variations without the need for physical models, saving both time and cost during the development cycle.

3. Improved Design Accuracy

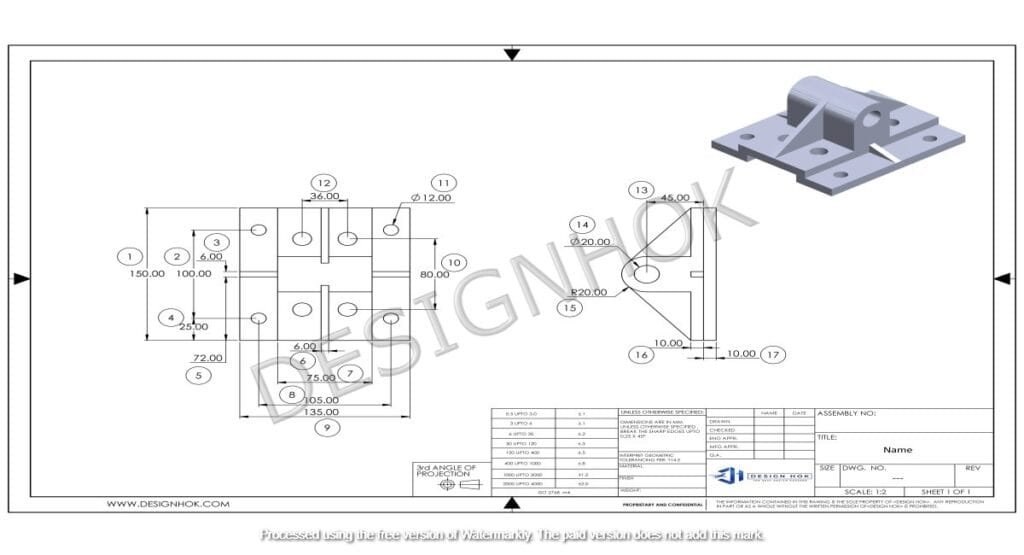

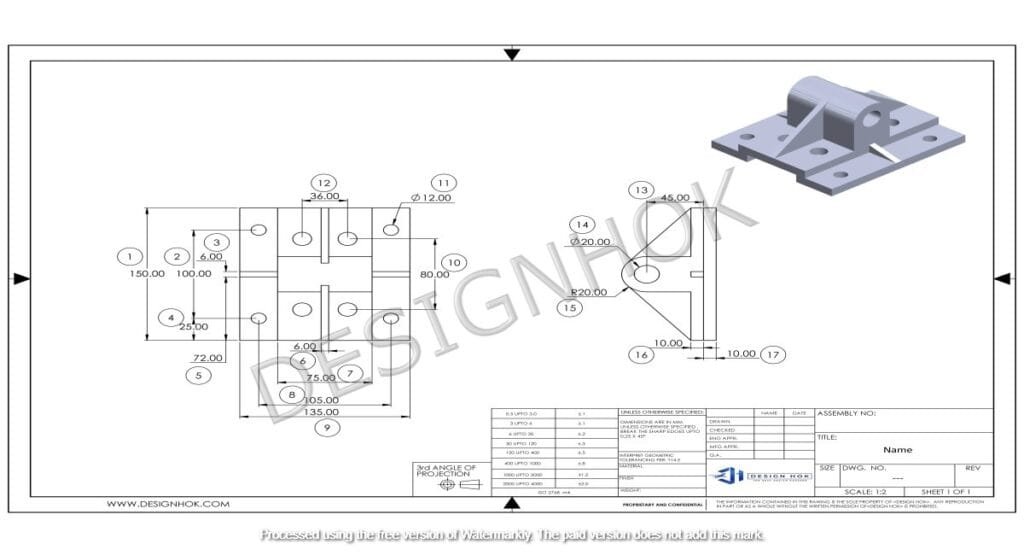

Precision is crucial in industrial design, especially when products require tight tolerances and perfect fitment with other components. With 3D modeling, measurements can be controlled down to the smallest unit, ensuring each part of the design aligns perfectly with manufacturing specifications.

CAD-based 3D modeling tools like SolidWorks, Fusion 360, or Rhino allow industrial designers to:

- Control geometries with exact dimensions

- Apply constraints and parametric controls

- Avoid design errors during production

This accuracy reduces the chance of expensive rework or tooling adjustments once the product moves to manufacturing.

4. Better Collaboration Between Teams

3D models are not only useful to designers—they’re essential communication tools for engineers, marketers, clients, and manufacturers.

Using formats like .STL, .STEP, or .OBJ, 3D files can be shared easily across departments and platforms. Engineers can run simulations, marketing teams can use 3D renders for promotional materials, and manufacturers can prepare production tooling—all from the same file.

This centralization reduces miscommunication and keeps everyone working from a single source of truth.

5. Cost-Effective Prototyping and Testing

Prototypes are critical for verifying design functionality, but building physical prototypes for every iteration is both costly and time-intensive. With 3D modeling, designers can simulate much of this process virtually.

Thanks to advancements in 3D printing, CNC machining, and digital rendering, 3D models can be:

- Rapidly turned into physical prototypes using additive manufacturing

- Simulated to test stress, load, temperature, and performance

- Adjusted based on real-world feedback

This makes prototyping faster, more accurate, and more affordable than ever before.

6. Creative Freedom and Flexibility

Traditional 2D drafting often limits creativity due to its linear and abstract nature. 3D modeling removes these barriers, giving designers a sandbox to explore complex shapes, surfaces, and forms that would be difficult to draw manually.

This flexibility allows for:

- Organic and ergonomic designs

- More imaginative product concepts

- Experimental use of materials and textures

At DesignHok, designers harness this creative freedom to produce bold and innovative solutions that meet both aesthetic and functional needs.

7. Improved Time-to-Market

In competitive industries, speed is a major advantage. Benefits of 3D Modeling for Industrial Designers shortens the time between initial concept and final production by streamlining design, review, and iteration stages.

By leveraging 3D modeling:

- Concept development becomes faster

- Feedback can be implemented in real-time

- Manufacturing-ready files are generated quickly

This results in quicker project completion and a shorter path from idea to shelf.

8. Support for Digital Manufacturing

As manufacturing becomes increasingly digital, 3D modeling is the bridge that connects design to production. Modern techniques like

- CNC machining

- Injection molding

- 3D printing

- Laser cutting

all rely on accurate 3D models for toolpath generation and part fabrication.

DesignHok uses 3D modeling to prepare manufacturing-ready models that meet the exact requirements of each process, ensuring seamless transition from design to production.

Conclusion

Benefits of 3D Modeling for Industrial Designers has revolutionized the way industrial designers create, test, and refine products. With its ability to enhance visualization, increase precision, speed up prototyping, and foster team collaboration, it’s no wonder that 3D modeling is now a foundational tool in the design process.

For firms like DesignHok, Benefits of 3D Modeling for Industrial Designers is more than just a technique—it’s a strategy for achieving innovation, quality, and client satisfaction. As industries continue to evolve, those who embrace the full power of Benefits of 3D Modeling for Industrial Designers will stay ahead of the curve, delivering designs that are not only beautiful but also functional, manufacturable, and future-ready.

FAQs: Benefits of 3D Modeling for Industrial Designers

Q1: Why is 3D modeling important in industrial design?

3D modeling provides accuracy, speed, and visual clarity in designing products. It allows industrial designers to create, test, and refine products before physical production, saving time and resources.

Q2: Can 3D modeling reduce production costs?

Yes. By identifying design flaws early, reducing the number of physical prototypes, and streamlining communication with manufacturers, 3D modeling significantly cuts costs.

Q3: Which software is best for 3D modeling in industrial design?

Popular choices include SolidWorks, Autodesk Fusion 360, Rhino, Blender, and CATIA. The best software depends on the project type and design goals.

Q4: Is 3D modeling helpful for small-scale designers or startups?

Absolutely. 3D modeling levels the playing field by giving small teams the ability to produce high-quality designs and prototypes without large investments in tooling.

Q5: How does 3D modeling improve collaboration in a design project?

It allows team members across departments to view, edit, and use the same model file, ensuring clear communication and consistent updates throughout the design process.

Q6: What’s the difference between CAD and 3D modeling?

CAD (Computer-Aided Design) focuses on technical and engineering aspects of design, while 3D modeling may include creative elements like textures, animations, and visual rendering. Many tools combine both features.

Q7: Can 3D models be used for marketing purposes?

Yes. High-quality renders and animations from 3D models can be used in promotional materials, product launches, websites, and presentations to attract investors or customers.