Introduction

Benefits of 3D Modeling for Design HOK has revolutionized the way design and engineering projects are executed. It allows designers, engineers, and architects to create highly detailed and realistic representations of their ideas before they are physically built. For a company like Design HOK, which specializes in mechanical design projects, Benefits of 3D Modeling for Design HOK, 3D rendering projects, and 2D drafting & engineering projects, adopting 3D modeling enhances efficiency, accuracy, and creativity in design processes.

This blog explores the key benefits of 3D modeling for Design HOK and why it is essential in modern design and engineering workflows.

1. Enhanced Visualization and Realism

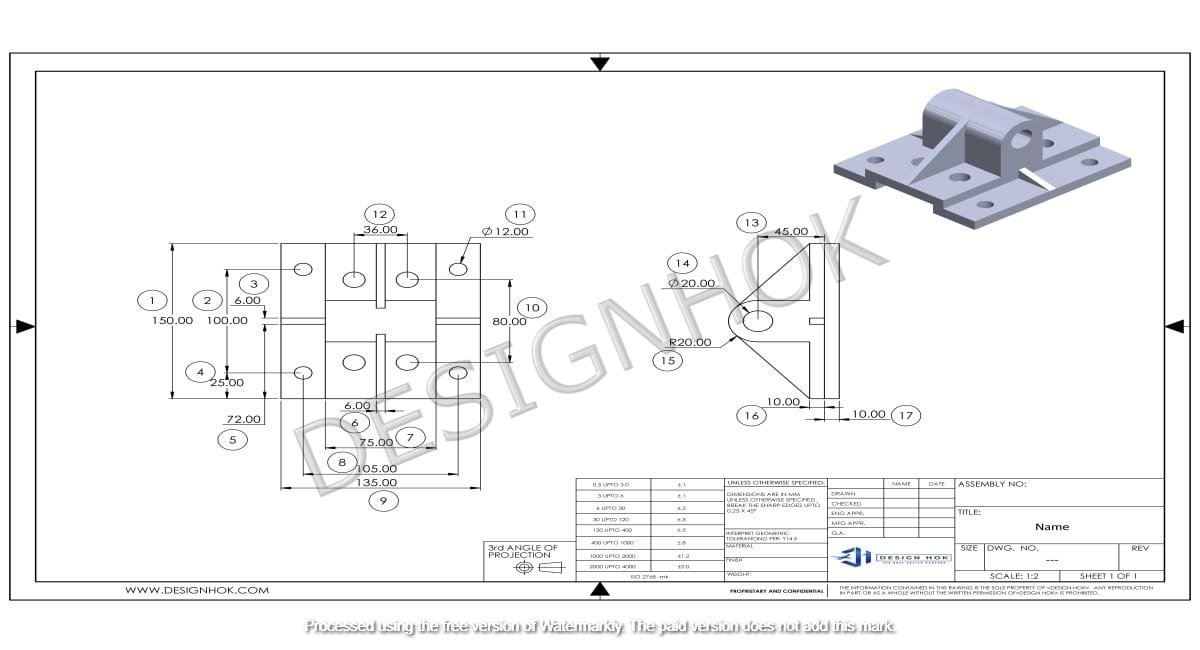

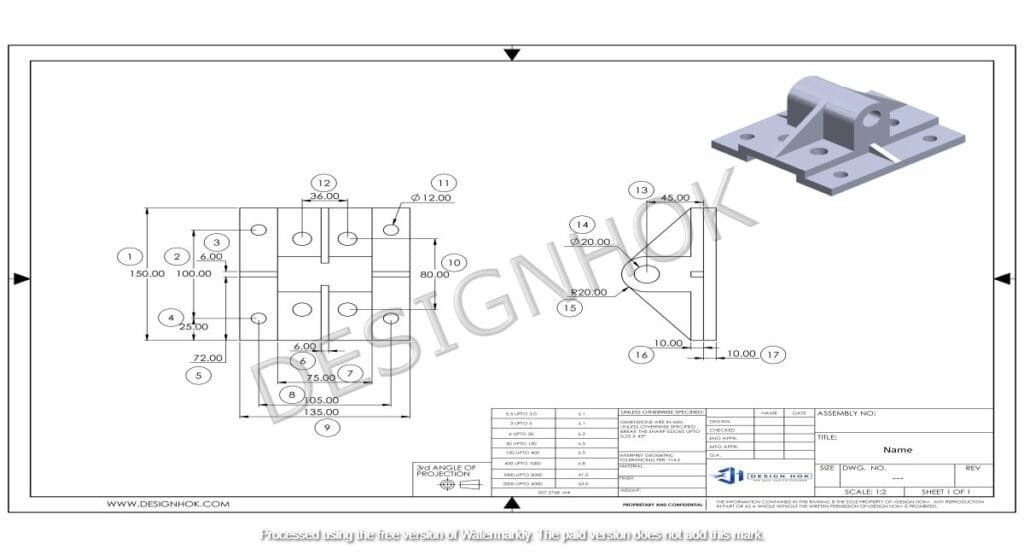

One of the primary advantages of Benefits of 3D Modeling for Design HOK is its ability to create highly detailed and realistic representations of a design. Unlike 2D drawings, which require interpretation, 3D models give clients and designers a clear, interactive view of the final product.

For Design HOK, 3D modeling helps in:

✔ Creating lifelike visualizations for clients.

✔ Detecting design flaws before actual production.

✔ Presenting design concepts in an easy-to-understand format.

This enhanced visualization improves communication between designers, clients, and stakeholders, reducing misunderstandings and project delays.

2. Improved Design Accuracy and Precision

Traditional 2D drawings often leave room for errors due to perspective and measurement limitations. However, 3D modeling ensures higher accuracy by enabling designers to create objects with precise dimensions and proportions.

For Design HOK, this means:

✔ Accurate representation of mechanical components.

✔ Reduction in costly errors during manufacturing.

✔ Consistency across multiple project designs.

Since 3D modeling eliminates human errors, projects are completed faster with fewer revisions and better overall quality.

3. Faster Design Process and Easy Modifications

Time efficiency is critical in any design project. 3D modeling speeds up the design process by allowing designers to:

✔ Quickly modify existing designs.

✔ Test multiple variations with ease.

✔ Automate repetitive design tasks.

For Design HOK, using 3D CAD software enables engineers to make real-time changes, reducing the time required to develop mechanical components, structures, and prototypes. This efficiency translates into cost savings and improved productivity.

4. Better Collaboration and Communication

In large-scale design projects, collaboration between different teams is essential. 3D modeling enhances teamwork and communication by allowing designers, engineers, and clients to visualize the same design in real time.

Benefits for Design HOK:

✔ Sharing 3D models with clients and stakeholders for feedback.

✔ Integrating different design disciplines seamlessly.

✔ Reducing miscommunication and rework.

By working with detailed 3D models, everyone involved in the project can understand the design clearly, leading to better decision-making and faster approvals.

5. Cost Efficiency and Resource Optimization

Design errors in mechanical and engineering projects can be extremely costly. However, with 3D modeling, potential problems can be identified early, saving time and money.

For Design HOK, this means:

✔ Reduced material waste due to precise calculations.

✔ Lower costs in prototyping and testing.

✔ Fewer revisions and adjustments in the final design.

By optimizing resources, projects are completed more economically while maintaining the highest quality standards.

6. High-Quality Prototyping and Manufacturing

One of the most significant advantages of 3D modeling is its role in rapid prototyping and manufacturing. With Benefits of 3D Modeling for Design HOK can create digital prototypes before moving into physical production.

This results in:

✔ Reduced prototyping costs.

✔ Faster product development cycles.

✔ More efficient manufacturing processes.

With 3D printing technology, 3D models can be converted directly into physical prototypes, speeding up product development and improving design accuracy.

7. Seamless Integration with Other Technologies

Benefits of 3D Modeling for Design HOK can be easily integrated with various advanced technologies such as:

✔ Virtual Reality (VR) and Augmented Reality (AR) – Allowing immersive design reviews.

✔ Simulation Software – Testing how designs perform under real-world conditions.

✔ CNC Machining and 3D Printing – Streamlining manufacturing processes.

For Design HOK, integrating 3D modeling with these technologies enhances innovation and improves product quality.

8. Increased Competitiveness in the Market

Companies that use Benefits of 3D Modeling for Design HOK gain a competitive advantage by delivering high-quality designs faster and more efficiently. Design HOK can use 3D modeling to:

✔ Attract more clients by showcasing detailed and realistic project designs.

✔ Stay ahead of competitors by offering innovative design solutions.

✔ Meet industry standards and requirements with ease.

By embracing cutting-edge 3D modeling techniques, Design HOK strengthens its reputation as a leader in design and engineering services.

Conclusion

Benefits of 3D Modeling for Design HOK is an essential tool for Design HOK that enhances visualization, accuracy, efficiency, and collaboration. By using advanced 3D modeling software, the company can create high-quality mechanical designs, engineering projects, and architectural renderings with greater precision and cost savings.

From faster prototyping to better communication with clients, the benefits of 3D modeling ensure that Design HOK remains at the forefront of innovation and excellence in design services.

Whether you are working on mechanical designs, 3D renderings, or detailed engineering projects, 3D modeling is the key to achieving efficiency, precision, and success.

Frequently Asked Questions (FAQ)

1. Why is 3D modeling important for Design HOK?

3D modeling enhances visualization, accuracy, and efficiency in design projects. It allows for better communication, faster modifications, and cost-effective prototyping.

2. How does 3D modeling improve design accuracy?

3D modeling eliminates human errors by providing precise measurements, realistic representations, and the ability to test multiple design variations before production.

3. Can 3D modeling help reduce costs in mechanical design?

Yes, by detecting design flaws early, 3D modeling reduces material waste, rework costs, and manufacturing errors, leading to significant cost savings.

4. What industries benefit from 3D modeling?

Industries such as mechanical engineering, architecture, automotive, aerospace, and construction benefit greatly from 3D modeling due to its ability to create detailed, realistic, and functional designs.

5. What software does Design HOK use for 3D modeling?

Design HOK uses advanced 3D CAD software such as AutoCAD, SolidWorks, and other industry-leading tools to create high-quality 3D models, mechanical designs, and engineering projects.

6. How does 3D modeling help in prototyping?

3D modeling enables the creation of digital prototypes, allowing designers to test, analyze, and improve designs before moving into physical production, thus saving time and resources.

7. Is 3D modeling better than 2D drafting?

Yes, 3D modeling provides more detail, better visualization, and higher accuracy than 2D drafting, making it ideal for complex design projects. However, 2D drafting is still useful for creating technical documentation and engineering blueprints.

8. How does 3D modeling support collaboration?

3D modeling allows designers, engineers, and clients to view, share, and modify designs in real time, leading to better communication and teamwork.