Introduction:

AS9100 a quality management system specifically created for flights to make them more comfortable for a perfect flight. Passengers want good experience at low price but when an aerospace firm use these standards it make it costly, because AS9100 is standard that help to craft an aero plain according to international standards. These design and engineering process is focused on safety, accuracy, and consistency in the system.

- What is meant by AS 9100 Quality Control for Aerospace?

AS9100 is a quality standard for international flights. It will benefit from the positive side of these standards. Although ISO 9001 is the primary standard, the aerospace industry has its own requirements. By combining innovation with well-disciplined quality control, aerospace management not only reduces risk and enhances safety with Design HOK.

To ensure safety, reliability, and high quality, companies should adopt additional requirements to prevent significant consequences from minor errors in the aerospace industry. The AS 9100 standard was formulated by the International Aerospace Quality Group (IAQG) for big aerospace companies, including Boeing, Airbus, and Lockheed Martin.

- The Role of AS 9100 in Aerospace Quality and safety

AS 9100’s safety benefits are vital for aerospace projects. Companies are able to reduce the likelihood of dangerous errors by identifying risks early in design and production. AS 9100 places emphasis on meticulous inspection and strict quality control to ensure that products meet high standards, leading to an improvement in their quality. There is a great deal of respect for the aerospace industry. AS 9100 help to maintain the quality of comfortable flight experience.

- How Design Hok uses AS 9100 quality standards

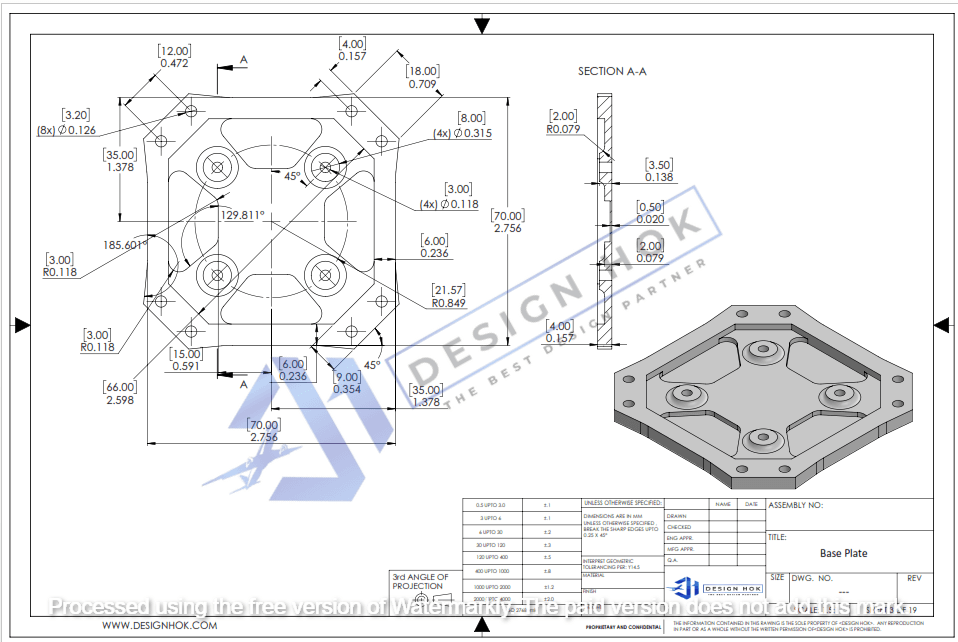

The high standards of the industry are met by our aerospace design and engineering work, and we ensure it by utilizing the AS 9100 quality control standard at Design Hok. The focus of all our projects is on accuracy, safety, and reliability. Mechanical design, 2D drafting, 3D modeling, and detailed technical drawings are some of the services we offer. The aerospace industry’s quality expectations are met by ensuring that every design is thoroughly tested, well-documented, and follows AS 9100 guidelines.

- Quality plan

At the beginning of each aerospace project, we create high-quality plans. Our clients’ requirements are understood by us through the establishment of clear objectives. Moreover, it outlines the tools, methods, and procedures required to accomplish these objectives. Identify any potential threats promptly and develop plans to avoid or minimize their impact.

- Document control

AS 9100 requires proper document control. We take great care in treating all drawings, specifications, and records at Design Hok. It is important to label all documents clearly, update them regularly, and store them safely. This prevents errors from arising from using outdated or incorrect information.

- Project validation

In the field of aerospace design, every design is carefully reviewed and tested. All standards and customer requirements are met, and our design is guaranteed to be accurate. Detecting and addressing errors before they become major problems can be achieved by checking everything from the beginning.

- Process management

A structured process is utilized by Design Hok to follow clear and well-defined steps for every stage in the design process. Ensuring quality and consistency necessitates the management of all processes from the initial idea to the final implementation. Checklists, regular reviews, and standard formats prevent important details from being overlooked.

- Employee training

AS 9100 standards are observed by our team during operations. Regular training sessions are crucial to maintain everyone’s up-to-date skills, particularly when new tools or updates are released.

- Customer focus

Customer satisfaction is a key element of AS 9100. At Design Hok, we maintain close contact with our customers throughout each project. We listen to their feedback and make changes to the design process based on their requirements.

- AS 9100 benefits for Design Hok customers

Design Hok customers enjoy the many benefits of AS 9100 certification. Top quality design. Our aerospace quality system helps you create designs that are accurate, reliable, and well-tested.

- Clear communication: Teamwork and confusion during projects are enhanced by documented processes.

- Reduced risk: Errors can be reduced and rework avoided to reduce risk, which can save time and money.

- Compliance with rules: Many aerospace projects require strict approvals. AS 9100 helps you easily meet national and international requirements.

- AS 9100 Aerospace Quality Management and Continuous Improvement

AS 9100 is not just about following rules. It also focuses on reliability, scalability, and precision. At Design HOK, we consistently go through projects to understand what worked well and what can be improved. These review help our experts to improve future project performance. We track important factors such as project completion time, customer satisfaction, and error and issues during work. This information helps improve processes. We follow all standard depending upon the projects.

- Challenges in Implementing AS 9100 Aerospace Quality Management

Like any quality system, AS 9100 also comes with some challenges. It needs time and effort to keep records updated, proper training for employees, and additional inspections that can sometimes slow down work. At Design Hok, we don’t see these as difficulties. Our view is that they are long-term investments. To avoid mistakes, save money, and build strong trust with our customers in the future, we need to pay extra attention today.

- Conclusion

Safe and reliable aerospace design is founded upon the quality standard AS 9100. To ensure accurate detail and high-quality results, this system is employed in all of our aerospace projects. It helps us deliver work our clients can depend on, while also helping our team continuously improve. AS 9100 sets Design Hok apart in an industry that prioritizes accuracy and trust.

Can you explain the difference between AS 9100 and ISO 9001?

AS 9100’s additional requirements, which are based on ISO 9001, must be met by the aerospace industry. Risk management, product traceability, and security are the main concerns of these additional rules.

- Is Design Hok AS 9100 solely utilized for aerospace projects?

While AS 9100’s quality standards are primarily intended for the aerospace industry, they can still be advantageous for projects in other industries.

- Is AS 9100 really beneficial for small businesses like Design Hok?

“Yes, small businesses like Design Hok can benefit from AS 9100. Your customers and partners will trust you if you follow this standard, demonstrating your commitment to quality.

- To improve customer satisfaction, what can AS 9100 do?

AS 9100 can help with error reduction, communication improvement, and delivery of high-quality products. This method is capable of enabling companies to meet customer requirements and deliver products on time.

- AS 9100 certification be necessary for aerospace activities?

Despite not being legally mandated, AS 9100 is still preferred or required by numerous aerospace companies. Negotiating contracts in the aerospace industry becomes easier with this certification.