- Introduction to AS9100 quality at Design HOK in engineering projects

AS 9100 quality control are a requirement for the aerospace, aviation, and defense industries. Despite using the ISO 9001 standard, these industries are still obligated to comply with stricter regulations. To manage and oversee every step of an engineering project, including the initial design through final product validation, the AS 9100 by Design is utilized. By using this standard, product traceability, reliability, and defect-free status are guaranteed. In industries such as Design HOK, AS 9100 is vital in ensuring safe and high-quality results.

- Overview of AS9100 quality control at design HOK and its Services

Design HOK is a company that employs engineers and designers to work in different technical fields. Services such as mechanical design, 3D modeling and simulation, 2D drawings, 3D rendering, product prototyping, and component design are available to the aerospace and automotive industries through the company. Design HOK has a strong focus on working with clients in industries such as aviation, energy, robotics, and manufacturing. The company’s strict quality standards are necessary for high precision and safety in these industries.AS 9100 quality control is required for all projects to guarantee industry compliance, minimize errors, and ensure accurate and reliable results.

- Why AS9100 Matters in Design HOK Projects

The significance of AS 9100 in the design of HOK projects.

Small design errors can cause significant economic losses and threaten lives in industries such as aerospace and defense. AS 9100 standards are adhered to by Design HOK for every project, regardless of its size. AS 9100 helps in HOK design.

Build confidence with clients from other countries

Make certain that your projects are clearly explained, documented, and reproducible.

Prevent quality issues by reducing errors

Continuously improve your design over time

Design HOK uses AS 9100 standards for all mechanical and modeling work, delivering quality results, safety, and reliable performance that customers can rely on.

- Basic Elements of Quality Control AS 9100

Quality planning and documentation

AS 9100 emphasizes good planning and clear documentation throughout the project, from initial idea to final implementation. This includes:

Set quality goals before starting design work

We use SolidWorks, so the project requires clear and concise documentation. We make a plan to handle all aspects of project. At Design HOK, we ensure that all design modifications, approvals, and inspections are completed. The standard project management process consists of the following steps.

- The management of design and development

The AS 9100 Design Control Standard is followed by Design HOK to guarantee that each project meets both quality and customer expectations. From the start of the design process, the client’s needs and applicable regulations are meticulously evaluated. To make sure everything runs smoothly, all design steps are checked regularly.

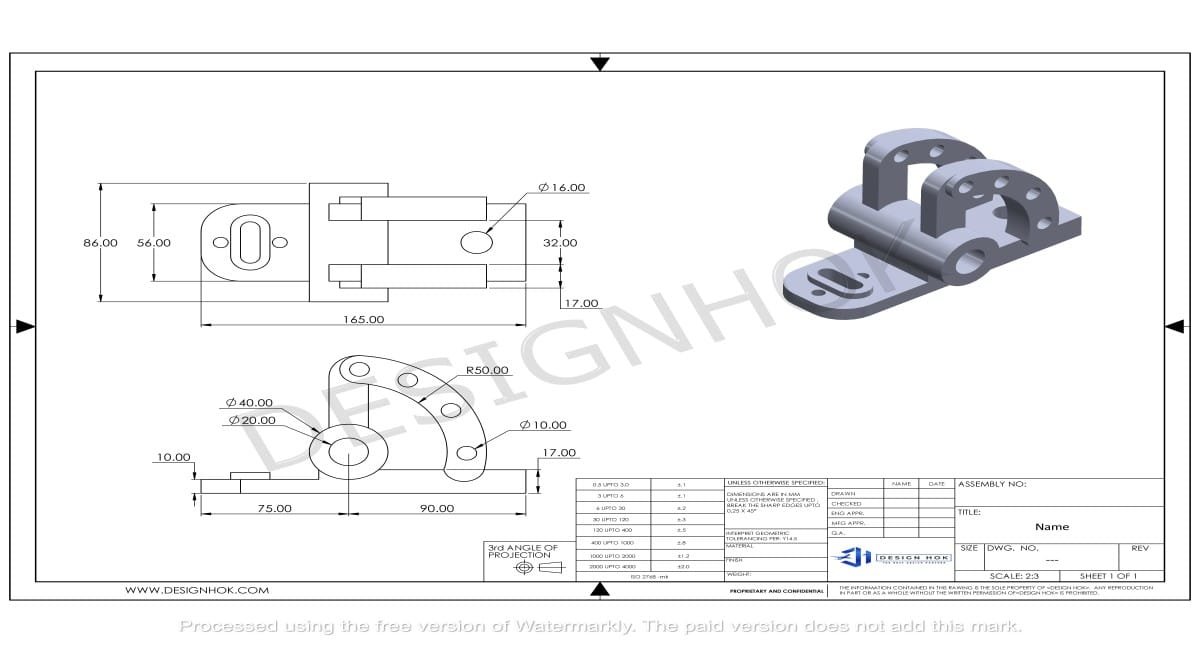

The company uses well-defined design verification and verification methods to ensure that the final design performs as required. Peer reviews, simulations, and prototype testing are performed to quickly identify and resolve issues. As a result, Design HOK provides accurate CAD models, detailed drawings, and reliable system-level assemblies with minimal errors.

- Security protocols and risk management

AS 9100 quality standard requires a strong focus on risk-based thinking. At Design HOK, we ensure that risk is managed by thoroughly inspecting designs and materials at every stage. At Design HOK, we ensure that risk is managed by thoroughly inspecting designs and materials at every stage. To make sure all parts are reliable, design and material safety must be checked. Additional security measures, such as backup functionality and crash protection, are added as needed. Product safety documentation is also constantly updated. This careful approach helps Design HOK create safe and reliable products such as aircraft mounts, drone structures, engine parts, and other aerospace components that meet stringent safety requirements.

- Supplier and Process Control

AS 9100 requires companies to carefully control their suppliers and outsourced work. At Design HOK, we follow these requirements by working only with suppliers that are certified to AS 9100 or ISO 9001. We use approved parts lists and controlled specifications to ensure the correct materials are used. All incoming materials and 3D models are checked before use. The supplier’s performance is regularly reviewed by monitoring quality results and response times.

These steps help us maintain a reliable and responsible supply chain for all manufacturing engineering activities.

- Validation and verification of products

Design HOK’s Quality Control team carefully checks the product at different levels according to AS 9100 standards before final delivery. To ensure that all dimensions are correct, the design and CAD drawings are reviewed.

Testing the performance of products is done using engineering simulations such as FEA and CFD. To ensure the correct fit of all parts during assembly, tolerance stack-up checks are performed.

Customers are also involved through walkthroughs and final approvals.

This process helps identify and remove design issues early and supports AS 9100’s goal of delivering defect-free products.

- Integrate AS 9100 into your Design HOK workflow

Design HOK utilizes a digital quality management system to comply with AS 9100 quality standards. Managing documents, tracking changes, preparing for audits, and ensuring project quality control are all integral to this system. The facilitation of collaboration between project managers, designers, and quality team members can be achieved through a single online platform. Improving communication and speeding up work can be achieved by doing this. The detection of problems early and continuous performance improvement can be achieved by regularly conducting internal audits and feedback.

- Case Study: How AS 9100 Improves HOK Design and Performance?

Aerospace drone assembly design

Design HOK was hired to develop an autonomous drone airframe design for a defense customer. The design process becomes more reliable and controllable by adhering to AS 9100 quality standards. The team was able to identify potential material fatigue issues during design reviews and fix them before production started. Supplier audits are performed to guarantee that all aluminum utilized is of high-quality aerospace-grade. The stability of the drone was ensured by conducting tests and simulations at an altitude of 20,000 feet.

Result:

Our client’s approval time was reduced by six months by obtaining military certification through these managed processes.

- AS 9100 Benefits for Aerospace Customers and Stakeholders

Design HOK offers many benefits to our customers by implementing AS 9100 quality control, including:

More reliable projects. Projects are less likely to experience delays or problems because of their predictability.

The process is likely to speed up if approval is received on the first try.

Faster authentication. Projects can be quickly moved from concept to certification to reduce wait times.

Make sure to save money in the long run. Over time, there will be overall savings resulting from less rework. The FAA, EASA, and NASA have established high standards that our processes meet.

These benefits are beneficial in an industry where safety and accuracy are crucial, boosting the chance of project success and increasing our customers’ confidence in our work.

- AS 9100 Quality Control Audit and Maintenance at Design HOK

Design HOK ensures compliance with AS 9100 quality control standards through regular inspections and audits.

An internal quality management system audit is planned to evaluate our quality management system.

It is also third-party audited to ensure it meets industry standards. Corrective action reports (CARs) and preventive actions can help you resolve and avoid problems.

Annual risk reviews help identify potential issues and update plans to address them. Our team is regularly trained on changes to AS 9100 standards to ensure each standard complies with the latest aerospace quality standards.

- Final thoughts

For Design HOK, AS 9100 Quality Control is more than just a checklist. It’s a mindset. Each stage of the project planning, implementation, and delivery is impacted by this factor. Design HOK is focused on providing clients with safe, reliable, and fully compliant solutions that incorporate AS 9100 standards in both mechanical design and CAD modeling.

Design HOK’s partnership allows you to work with a team that adheres to global quality standards in the aviation and defense sectors, regardless of your industry.

- Could you elaborate on how AS 9100 is significant for Design HOK projects?

AS 9100, a quality standard, has been established to target the aerospace and defense industries. A methodology is employed by Design HOK to guarantee that all projects meet high safety and quality standards.

- What is the process for Design HOK to incorporate AS 9100 into its mechanical designs?

AS 9100 quality control is used by Design HOK through proper documentation management, risk management, design testing, and supplier vetting throughout the design process.

Is AS 9100 quality control certified by Design HOK’s suppliers?

A network of suppliers certified by AS 9100 or ISO 9001 is what Design HOK does. You can be certain that the materials and parts meet the same standards and are of high quality.

- What fields would reap benefits from a design process that complies with HOK AS 9100?

AS 9100 quality control standards ensure that the Design HOK process benefits industries like aerospace, defense, automotive, robotics, and manufacturing.

- Does Design HOK comply with AS 9100 quality control standards make it feasible for small businesses or startups to use it?

Design HOK offers solutions that are flexible and comply with AS 9100 quality control for businesses of all sizes, regardless of their size, whether it’s a small startup or a large, established entity.