Description:

Discover how 3D modeling revolutionizes engineering design and innovation at DesignHok. From conceptual visualization to manufacturing support, learn the key applications and benefits of 3D modeling in engineering.

In the rapidly advancing world of engineering, precision, efficiency, and innovation are the keys to success. At DesignHok, 3D modeling plays a vital role in pushing the boundaries of what engineers and designers can create. This digital technique has transformed how ideas move from initial concepts to fully functional products, especially in mechanical, civil, and industrial projects.

Let’s take a deep dive into the various Applications of 3D Modeling in Engineering, exploring how it helps DesignHok and its clients bring complex ideas to life with unmatched accuracy.

1. Conceptual Design and Visualization

The early stages of any engineering project require clear and detailed conceptual designs. Applications of 3D Modeling in Engineering allows engineers to create virtual prototypes that showcase a project’s look, function, and structure before anything is physically built.

At DesignHok, our designers use Applications of 3D Modeling in Engineering software to build realistic models that clients can view from every angle. This helps clients visualize their ideas more effectively than traditional 2D drawings. It also enables early-stage feedback and adjustments, which significantly improves design quality and reduces costly revisions later.

2. Product Development and Prototyping

In product engineering, Applications of 3D Modeling in Engineering accelerates the development process. Engineers use it to create digital versions of products and systems, simulate their performance, and make necessary design improvements — all before any physical prototype is produced.

DesignHok specializes in turning ideas into digital prototypes that are not only visually accurate but also mechanically functional. This virtual testing process identifies problems early, supports material selection, and enhances product performance — saving both time and money.

3. Engineering Analysis and Simulation

3D models are essential for running detailed simulations and engineering analysis. Finite Element Analysis (FEA), Computational Fluid Dynamics (CFD), and stress tests can be performed on a digital model to test the durability, heat resistance, or aerodynamic properties of components.

At DesignHok, our engineering team uses 3D models to simulate real-world conditions such as load, vibration, temperature, and movement. These simulations provide valuable data that guide engineering decisions and ensure that the final product will meet performance standards and safety regulations.

4. Manufacturing and Fabrication Support

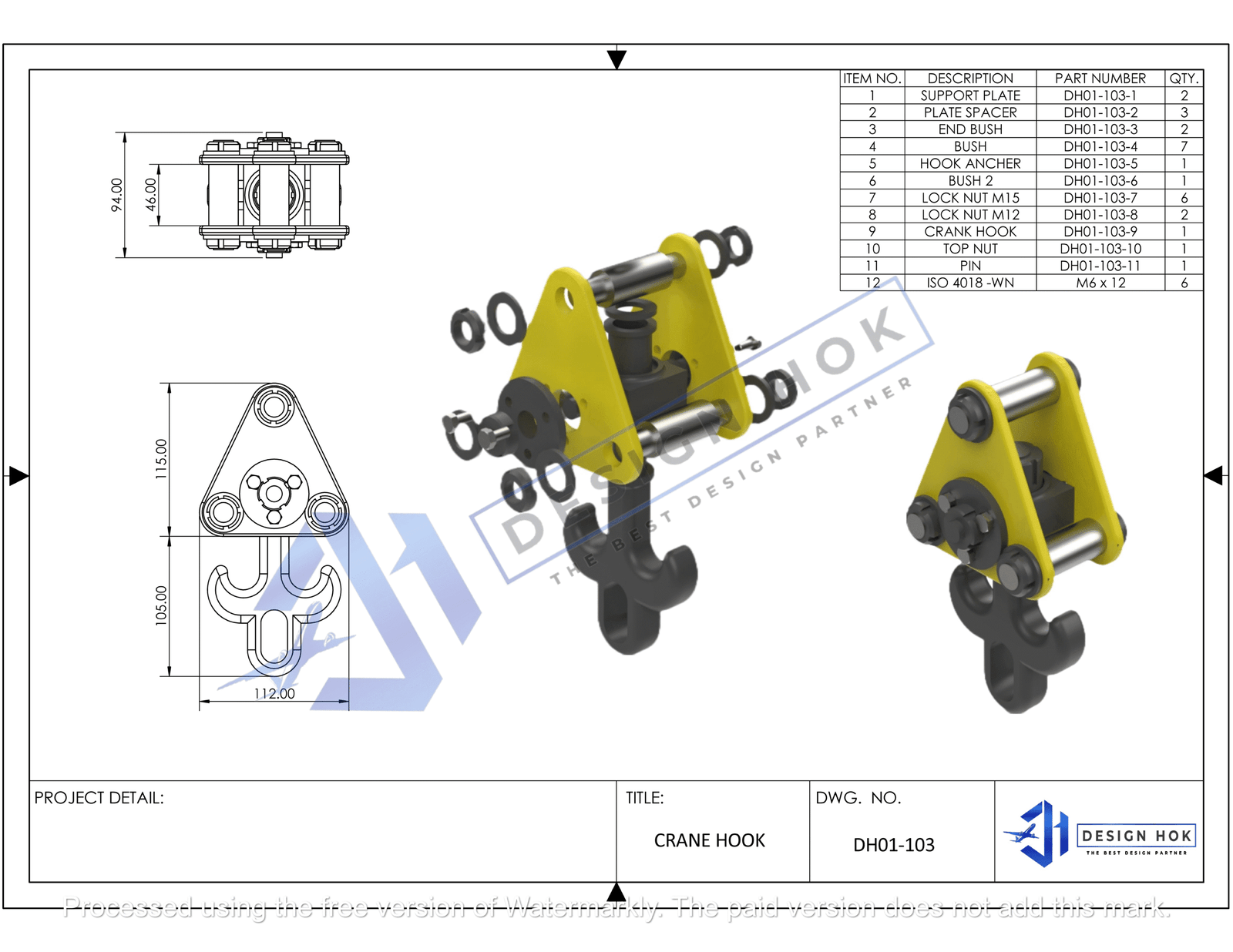

Modern manufacturing heavily depends on accurate digital blueprints. 3D modeling provides precise geometric data that can be directly used in CNC machines, 3D printers, and other advanced manufacturing technologies.

DesignHok’s 3D models are created with manufacturing in mind. We ensure that our designs are not only functional but also practical to produce. Our digital files are compatible with various fabrication systems, reducing translation errors and improving production efficiency.

5. Assembly and Mechanism Visualization

Applications of 3D Modeling in Engineering helps engineers visualize how components fit and move together in assemblies. This is particularly important in mechanical engineering, where moving parts must interact smoothly.

At DesignHok, we create assembly models that show the interaction between every part. These models reveal potential interference, misalignments, or assembly challenges. By identifying such issues early, we help prevent delays and minimize material waste during assembly.

6. Design Documentation and Communication

Clear communication is essential in engineering projects involving multiple teams. 3D models act as a universal language that communicates design intent more effectively than 2D drawings alone.

DesignHok uses 3D models to generate detailed exploded views, section cuts, and animations that explain complex systems in simple terms. These visuals are used in project documentation, client presentations, and team collaboration, ensuring everyone understands the design accurately.

7. Customization and Iteration

In today’s competitive engineering world, customization is a huge advantage. 3D modeling allows for quick design modifications without starting from scratch. This flexibility is crucial for creating client-specific solutions.

DesignHok uses parametric modeling techniques that allow us to adjust dimensions, materials, or features easily. Clients often request small changes, and with 3D models, we can provide rapid iterations and updates, delivering final results faster.

8. Virtual Reality (VR) and Augmented Reality (AR) Integration

Emerging technologies like VR and AR rely heavily on 3D models. Engineers and clients can explore and interact with their designs in a fully immersive environment.

At DesignHok, we incorporate VR-ready 3D models that offer an interactive design experience. Clients can “walk through” facilities, “rotate” machines in 3D space, and understand spatial relationships better than ever before.

9. Construction and Infrastructure Planning

In civil and structural engineering, Applications of 3D Modeling in Engineering assists with planning large-scale construction projects. From bridges and roads to buildings and industrial plants, 3D models provide a realistic overview of how structures will function in their environment.

DesignHok creates detailed infrastructure models that consider topography, environmental impact, and structural behavior. These models guide contractors, architects, and engineers throughout the construction phase, reducing errors and keeping projects on track.

10. Cost Estimation and Resource Management

Accurate project estimation depends on clear and complete design data. 3D models help engineers and project managers understand the quantity of materials needed, potential construction challenges, and the associated costs.

At DesignHok, we use Applications of 3D Modeling in Engineering to generate Bill of Materials (BOMs), identify resource needs, and optimize layouts for efficient material use. This helps clients manage budgets more effectively while avoiding unnecessary expenditures.

Conclusion

Applications of 3D Modeling in Engineering has revolutionized the engineering landscape. It allows for better design accuracy, faster prototyping, improved collaboration, and reduced production costs. At DesignHok, we use cutting-edge Applications of 3D Modeling in Engineering tools to ensure our engineering solutions are innovative, practical, and reliable.

Whether you’re developing a new mechanical product, building an industrial plant, or designing infrastructure, Applications of 3D Modeling in Engineering is the bridge that turns your vision into reality. With its wide range of applications, it’s clear that Applications of 3D Modeling in Engineering` isn’t just a trend — it’s a fundamental tool in modern engineering design.

FAQs: Applications of 3D Modeling in Engineering

Q1: What industries benefit from 3D modeling in engineering?

A: Industries such as mechanical engineering, civil engineering, automotive, aerospace, architecture, and manufacturing all benefit from 3D modeling by improving design, prototyping, and production processes.

Q2: How does 3D modeling improve product development?

A: It allows for rapid prototyping, design validation, simulation, and easy modifications, which help speed up development while reducing costs and errors.

Q3: Can 3D models replace physical prototypes?

A: While 3D models can’t completely replace physical prototypes in all cases, they reduce the number of physical iterations needed by allowing thorough virtual testing and visualization.

Q4: What software is commonly used for 3D modeling in engineering?

A: Popular 3D modeling software includes SolidWorks, AutoCAD, Fusion 360, CATIA, and Siemens NX. At DesignHok, we use industry-standard tools tailored to each project.

Q5: Is 3D modeling helpful in small engineering projects?

A: Yes, 3D modeling benefits both large and small projects by improving clarity, communication, and design efficiency, regardless of scale.

Q6: How does DesignHok ensure 3D models are manufacturing-ready?

A: We use precise modeling techniques, include tolerances, and export files in formats compatible with modern manufacturing systems, ensuring a smooth transition from design to production.