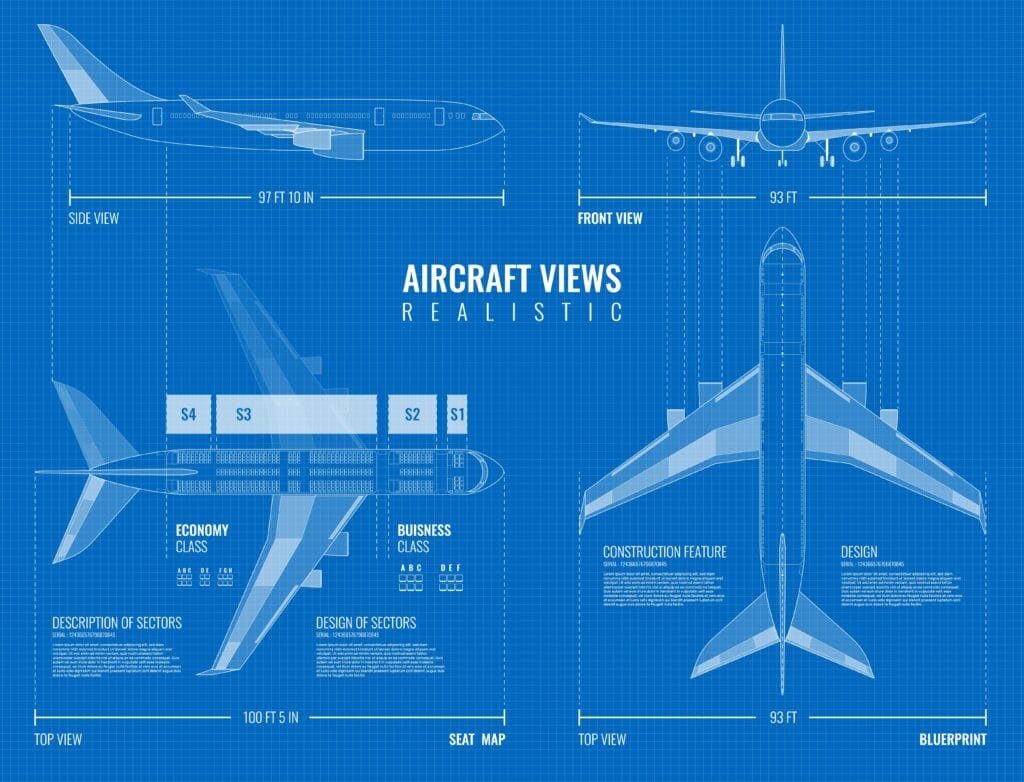

One of the most difficult jobs in engineering is to sketch an aircraft. This means avoiding any mistakes and ensuring the aircraft is safe. Today, CAD tools play a big role in aircraft design. Engineers use them to create, test, and improve parts before building them.

Today, we will understand Aircraft System Design CAD for the modern age. Moreover, we will also know the importance, tools, hurdles, and future trends.

1. What Is Aircraft System Design CAD?

It means using computer software to plan, model, and test aircraft systems. These can include:

- Hydraulic systems

- Electrical wiring

- Avionics

- Engine controls

- Landing gear

- Fuel systems

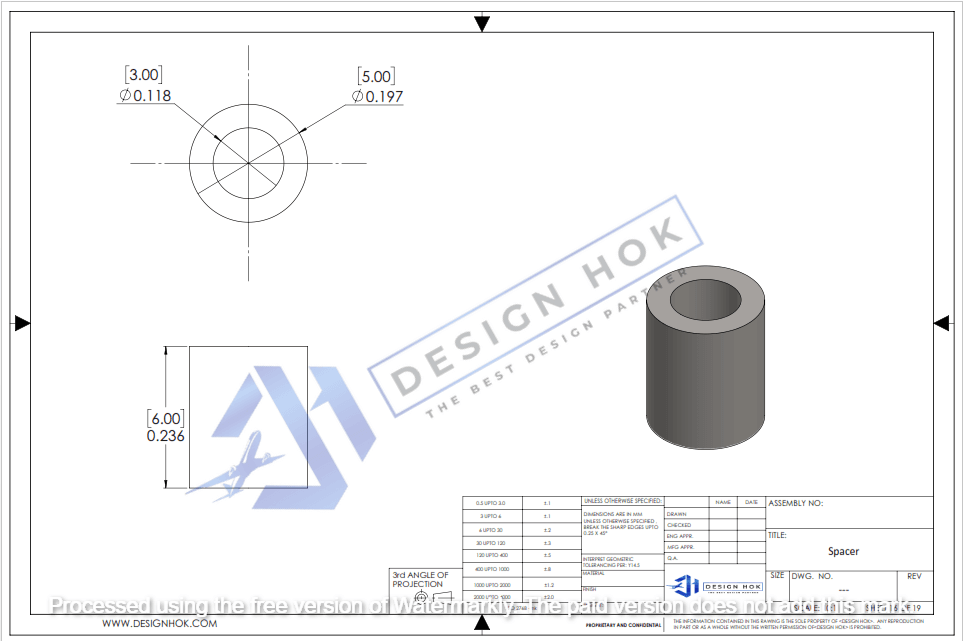

You can make 2D drawings and 3d models accurately with the help of CAD. These guide production and reduce errors.

Aircraft require numerous systems to function effectively. A small mistake can cause big safety issues. CAD helps by:

- Making accurate visual models

- Let’s you do quick edits

- It helps you in carrying out tests like pressure or airflow checks

- Helping teams work together worldwide

This saves time, money, and materials. So, this is Aircraft System Design CAD for the modern age.

2. Core Parts Designed with CAD

- Structure – wings, fuselage, tail, cockpit frame

- Electrical – wiring, circuits, lights

- Hydraulic & Fuel – pumps, pipes, tanks, valves

- Avionics – sensors, GPS, radar, control systems

3. CAD Software Used in Aerospace

CATIA – full aircraft modeling

SolidWorks – parts and layouts

Siemens NX – advanced 3D, analysis, CAM

AutoCAD – 2D wiring and layouts

ANSYS – stress, flow, and thermal tests

4. Advantages of CAD

- It ensures higher accuracy

- You save your time on edits and upgrades

- It minimizes costs by reducing prototypes.

- You can work as a team across locations

- It gives you better documentation for production

5. Testing By CAD

You can simulate many tasks using modern CAD tools. These include:

- Transfer of heat in engines

- Fuel and cooling fluid flow

- Stress and fatigue in structures

- Aerodynamics in wind tunnel models

6. Complete Design to Production Cycle

CAM – guides machines to make parts from CAD files

CAE – tests parts under heat, stress, or pressure

Together, they form a digital process from design to production.

7. Hurdles

- Very complex with thousands of parts

- Software costs are high

- Takes time to learn

- File issues if teams use different software

8. CAD in the Coming Decades

- Cloud CAD for real-time teamwork

- AI tools for better designs

- VR for aircraft walk-throughs

- Direct 3D printing from CAD models

9. Beginning A Career in Aircraft CAD

- Get to know the basics with AutoCAD or SolidWorks

- Take courses in CATIA or NX

- Study aerospace if possible

- Start working on small projects

- You can begin by applying for internships in aerospace firms

Summary

Designing has revolutionized with the introduction of CAD. From fuel systems to control panels, it makes work faster, cheaper, and safer. For anyone in aviation, learning CAD is now a must. Every model requires a perfect shape, which could beachieved with precision design. Design Hok is the best choice for flawless CAD models.

FAQs

What is Aircraft System Design CAD?

It refers to using CAD software to create and simulate systems in an aircraft, such as electrical, fuel, hydraulic, and structural components.

What is

What is the best software for CAD designing?

CATIA, SolidWorks, and Siemens NX are top choices.

Should I use AutoCAD?

Yes, you can use it, but mostly for 2D layouts.

What are the advantages of CAD designing?

You get Accuracy, cost savings, faster work, and better teamwork

Is it necessary to have a degree for designing?

Not always. CAD skills and a good portfolio can be enough.

What tools or software will be used in CAD?

Tools include Cloud tools, AI, VR, and 3D printing.