The aerospace industry is super advanced and really interesting in the world of engineering. Every plane, rocket, and satellite begins as a basic concept — eventually turned into a detailed 3D design before turning into an actual flying vehicle. Aerospace 3D modeling is a key player in how engineers come up with, check out, and put together planes and space gear. If you’ve ever been curious about how planes or rockets are crafted on computers before they’re actually made, this guide’s got you covered.d Let’s dive into what aerospace 3D modeling is all about, how it functions, the software tools involved, and why it’s crucial for today’s aviation and space adventures.

What Is Aerospace 3D Modeling?

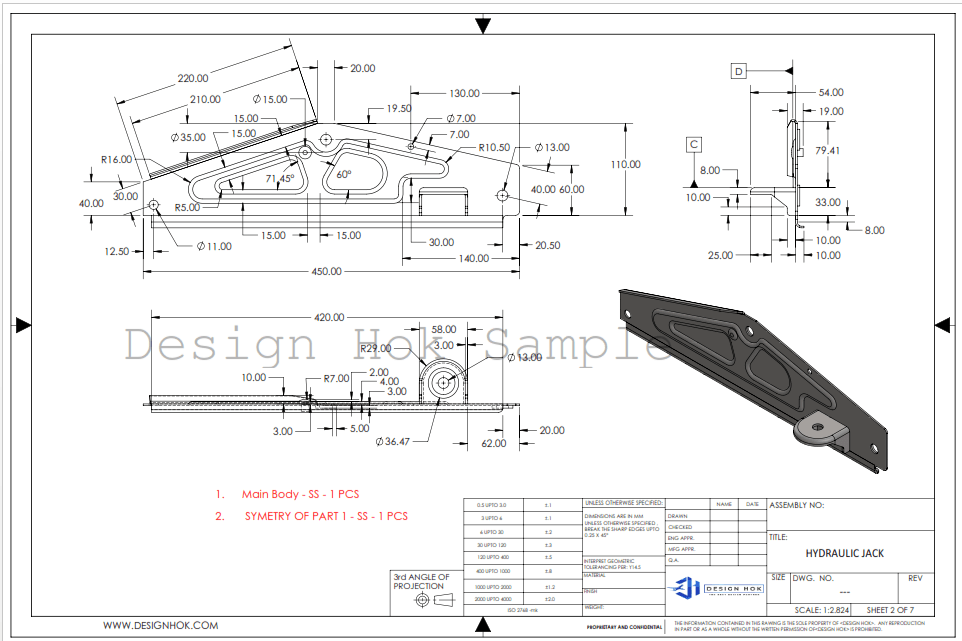

It’s the process of creating a 3D representation of any aircraft or any part used in the system. They use special softwares of Design HOK, every detail, from the outer space of the plane to the smallest screw in the engine. In easy words, 3D modeling helps in visualization and inspecting designs before they go into production. It saves time, reduces cost, which allows engineers to find the issue early so they can fix it.

Here are a few areas to cover the wide range of applications

- Engineers design aircraft wings in this industry.

- They design rocket engines and bodies of spacecraft.

- These engineers also design the turbine blades and jet engines.

- Engineers design cabin interiors and control style.

By creating accurate 3D models, engineers can simulate how a part will perform under real conditions such as pressure, temperature, and vibration.

Why is 3D Modeling Important in Aerospace Engineering?

This industry deals with safety and performance very strictly. A single design error can cause massive financial loss or may even be worse. That’s why the 3D model of design is very important.

Here’s the reason why it’s so important:

- Visualization Before Production

Engineers and designers can visualize the design through 3D modeling, which helps in identifying the flaws early. - Improved Accuracy

The 3D model has improved accuracy, and it’s much better than traditional 2D drawings, because it can’t capture complex shapes. This modeling provides detailed geometry and makes production more accurate. - Simulation and Testing

The inspection can be run on 3D models to check performance, strength, and aerodynamics before beta testing. - Time and Cost Savings

It reduces the number of physical prototypes needed. This saves both time and money during the design phase. - Easy Collaboration

Our Teams across different departments, like design, testing, and manufacturing, can work on the same 3D model. This ensures consistency and teamwork.

The Process of Aerospace 3D Modeling

Here’s the workflow for the engineer step-by-step when creating a 3D model in the aircraft industry

Step 1: Concept and Research

All aerospace project begins with an idea, which could be designing anything that solves a real-world problem. Engineers research existing designs, materials, and performance needs. They gather data about aerodynamics, strength, and weight requirements.

Step 2: 2D Sketch or Drawing

Before jumping into 3D, engineers usually make 2D sketches. These drawings define the basic dimensions and shapes of the parts.

Step 3: Creating the 3D Model

Using CAD (Computer-Aided Design) software like CATIA or SolidWorks, the designer creates a 3D model from the 2D sketch. This includes detailed shapes like holes and curves.

Step 4: Assembly

In this, all the separate parts are combined digitally inside software to form the structure of the machinery.

Step 5: Simulation and Analysis

Engineers test the machine virtually using different software. This shows how the design reacts under stress or air pressure. They made adjustments based on the result.

Step 6: Prototyping and Manufacturing

If it passes all tests, it’s used to create a prototype. The final product is then tested in the real world.

Applications of 3D Modeling in Aerospace

It has countless uses in the aerospace field. Some major areas include:

- Aircraft Design

An airplane is created as a 3D model. This helps engineers inspect how it will perform before making the real thing. It improves the weight balance, which makes aircraft faster and safer. - Spacecraft Design

Aerospace engineers also use 3D modeling for designing spacecraft, which shows how the vehicle will perform during real flight operations. This reduces the risk of failure. - Engine Components

These are highly complex models. It helps to test the smallest details, like turbine blades and the cooling system, before actual manufacturing. - Maintenance and Repair

You can create digital twins, which help the engineers to test and inspect the plane for maintenance. - Training

It’s a valuable tool to train new engineers and mechanics. They provide a realistic view of aircraft in virtual reality.

Benefits of Aerospace 3D Modeling

Here are some of the most important benefits of Aerospace 3D modeling.

- It has a high accuracy. It can measure complex models with extreme accuracy.

- Engineers can identify issues before production, which reduces risk

- Engineers use VR models, which reduce the time between concept and testing.

- All team members and the client can easily understand 3D models.

- It can improve performance by simulating airflow and temperature.

In easy words, 3D modeling makes aerospace design faster and safer.

Conclusion

Aerospace 3D modeling is the key to designing today’s planes and spacecraft. This lets engineers sketch out, plan, trial, and tweak their concepts with amazing precision — way before anything’s actually constructed. For newbies, diving into aerospace 3D modeling kicks off a journey into a realm of creative and innovative possibilities. If you’re thinking about designing planes, rockets, or satellites, getting the hang of 3D modeling is the key move to make those dreams come true

Engineering know-how and digital design tools are pushing the future of flying, and it all starts with a 3D model