Description:

Explore the powerful advantages of 3D modeling in the manufacturing industry. From improved design accuracy to faster production, this blog explains how Advantages of 3D Modeling for Manufacturing revolutionizes the way manufacturers develop and deliver quality products.

Introduction

Advantages of 3D Modeling for Manufacturing has undergone a massive transformation over the last few decades, largely driven by advancements in digital technology. At the heart of this evolution is Advantages of 3D Modeling for Manufacturing—a process that creates detailed digital representations of physical objects. Whether used for automotive parts, electronics, furniture, or industrial machinery, Advantages of 3D Modeling for Manufacturing is now an essential step in turning concepts into actual products.

Gone are the days when manufacturers relied solely on 2D sketches and physical prototypes. Today, 3D modeling provides precision, efficiency, and flexibility in design and production processes. This blog will explore the Advantages of 3D Modeling for Manufacturing, highlighting why it’s a game-changer in modern product development.

1. Improved Design Accuracy

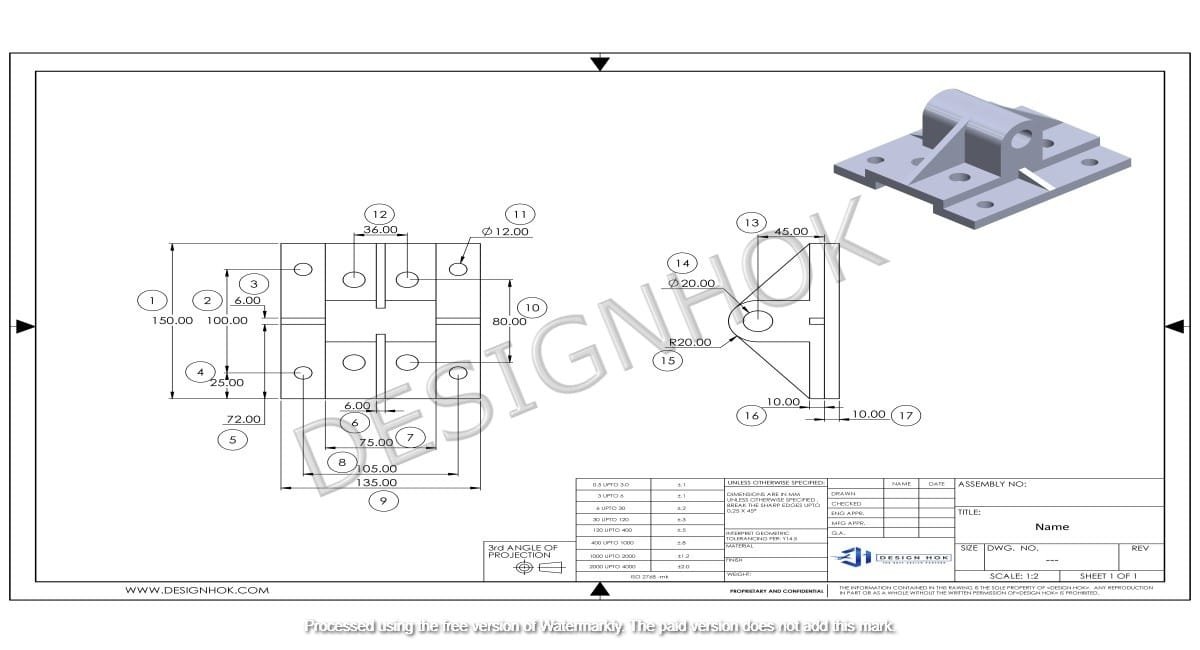

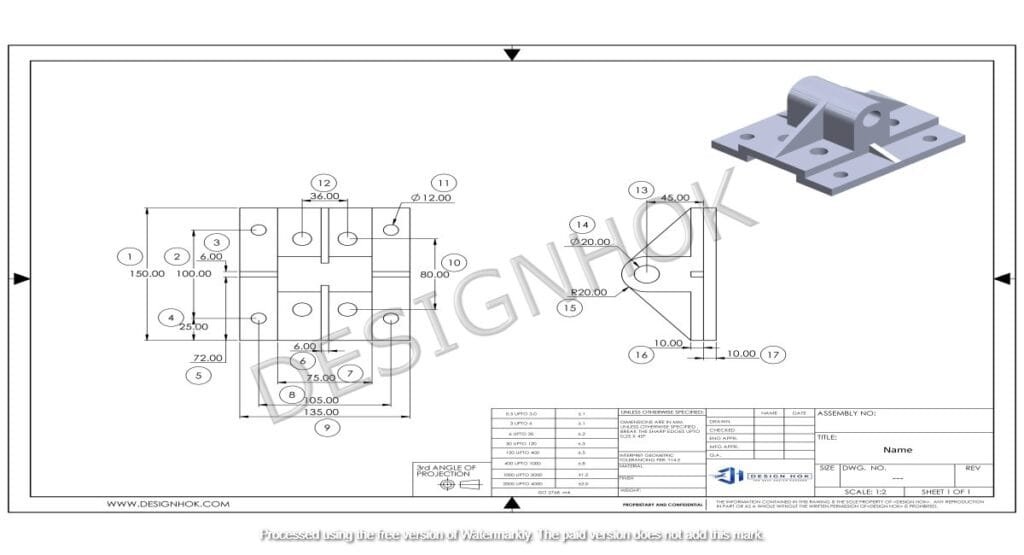

One of the most critical advantages of 3D modeling is the precision it offers. Unlike traditional 2D drawings that can sometimes be open to interpretation, 3D models leave little room for ambiguity. They provide detailed views from every angle, including internal structures, complex surfaces, and exact dimensions.

This level of detail helps designers identify potential issues before production even begins. For manufacturers, this translates to fewer errors, reduced material waste, and lower costs due to rework.

2. Faster Prototyping and Iteration

In the past, creating a prototype was time-consuming and expensive. With 3D modeling, manufacturers can quickly generate digital prototypes, test various design concepts, and make adjustments in a matter of hours.

3D printing, also known as additive manufacturing, complements this process by turning digital models into tangible objects almost instantly. This rapid prototyping enables manufacturers to iterate designs faster, receive feedback sooner, and speed up the product development cycle.

3. Enhanced Collaboration and Communication

Advantages of 3D Modeling for Manufacturing makes it easier for teams—engineers, designers, and clients—to collaborate effectively. With a 3D model, everyone can visualize the product clearly, regardless of their technical background.

Sharing a 3D model is more engaging than showing a flat drawing. It eliminates confusion and ensures that stakeholders are aligned with the vision of the final product. Many manufacturers now use cloud-based platforms that allow real-time collaboration on models, leading to faster decision-making and better project outcomes.

4. Streamlined Advantages of 3D Modeling for Manufacturing Process

Once a 3D model is finalized, it can be directly used for various stages of manufacturing. Computer-aided manufacturing (CAM) systems use these models to generate tool paths and machining instructions. This automation reduces manual labor, speeds up production, and improves consistency.

Moreover, with 3D models, manufacturers can simulate and plan the entire production process ahead of time, minimizing delays and avoiding unexpected issues during assembly.

5. Better Quality Control

Quality is everything in manufacturing, and Advantages of 3D Modeling for Manufacturing plays a crucial role in ensuring it. Models can be used to simulate how a product behaves under stress, heat, or pressure—helping identify weak points before they become costly problems.

Using 3D models in inspection tools and machines also enables manufacturers to compare real-world parts with their digital counterparts, ensuring they meet exact specifications. This digital verification process enhances product quality and reduces returns or failures.

6. Customization Made Easy

Modern consumers demand personalized products, whether it’s a piece of jewelry or a medical implant. 3D modeling makes mass customization possible without needing to redesign from scratch each time.

Manufacturers can quickly modify existing 3D models to suit individual customer requirements. This flexibility opens doors to new markets and allows companies to offer unique, customer-centric products at scale.

7. Cost Reduction

Cost savings is one of the biggest motivators for adopting 3D modeling in manufacturing. Here’s how it helps:

- Fewer mistakes due to better design accuracy.

- Reduced prototyping costs with digital and 3D printed versions.

- Lower labor costs with automated manufacturing tools.

- Less material waste through optimized design and simulation.

By eliminating inefficiencies and preventing expensive errors, manufacturers can bring products to market more affordably and competitively.

8. Faster Time to Market

In today’s fast-paced world, getting a product to market quickly can be the difference between success and failure. 3D modeling accelerates every stage of the product lifecycle—from design and validation to tooling and production.

By identifying design flaws early, reducing prototype development time, and streamlining production, manufacturers can cut lead times dramatically. This speed not only improves profitability but also allows companies to respond to market trends in real time.

9. Better Documentation and Compliance

Manufacturing in regulated industries such as aerospace, automotive, and healthcare requires strict documentation for quality and safety. 3D models can be used to generate technical drawings, specifications, and compliance reports.

These documents can be automatically updated whenever the model changes, ensuring accuracy and reducing the risk of outdated information. With all data tied to the digital model, record-keeping becomes easier and more reliable.

10. Integration with Emerging Technologies

3D modeling also lays the groundwork for integrating with Industry 4.0 technologies, such as:

- Digital twins: Real-time simulations of physical products.

- Virtual reality (VR): Immersive product reviews and training.

- Augmented reality (AR): Visualizing products on the production floor.

- Generative design: AI-driven design optimization.

As manufacturing continues to evolve, 3D modeling remains at the core of these innovations, ensuring businesses are future-ready.

Conclusion

The Advantages of 3D Modeling for Manufacturing are clear and far-reaching. From enhanced precision and faster development to cost savings and better collaboration, Advantages of 3D Modeling for Manufacturing has become a critical tool for modern manufacturers. It empowers companies like DesignHok to design smarter, produce faster, and deliver higher-quality products that meet today’s complex demands.

Whether you’re launching a new product, optimizing a production line, or exploring custom solutions, embracing Advantages of 3D Modeling for Manufacturing is a smart investment. It’s not just about creating shapes—it’s about unlocking new possibilities in how things are imagined, built, and improved.

FAQs: Advantages of 3D Modeling for Manufacturing

Q1: What industries benefit most from 3D modeling in manufacturing?

Industries such as automotive, aerospace, consumer electronics, medical devices, and industrial equipment all benefit greatly from 3D modeling due to their need for precision and complex parts.

Q2: Is 3D modeling only used during the design phase?

No. 3D modeling supports many stages of manufacturing, including prototyping, tooling, simulation, production, inspection, and even marketing.

Q3: Can 3D models be used directly for 3D printing?

Yes. Most 3D modeling software allows exporting models in formats like STL or OBJ, which are compatible with 3D printers.

Q4: How does 3D modeling help reduce production costs?

It minimizes design errors, speeds up development, reduces material waste, and enables automated manufacturing—all contributing to lower costs.

Q5: Do small manufacturers benefit from 3D modeling as much as large companies?

Absolutely. 3D modeling levels the playing field, allowing small manufacturers to design and test products efficiently without high upfront costs.