2D CAD vs 3D CAD key differences between 2D CAD and 3D CAD in the design process and learn how each impacts efficiency, visualization, and innovation at Design Hok.

Introduction:

Understanding 2D CAD vs 3D CAD in Modern Design

In the realm of engineering and product development, Computer-Aided Design (CAD) has become an essential tool for designing and creating everything from small mechanical parts to large complex systems. Over the years, CAD technology has evolved significantly, giving rise to two primary forms: 2D CAD vs 3D CAD. Both play a critical role in design processes, but each offers unique features that impact how designs are visualized, analyzed, and ultimately produced. At Design Hok, the choice between 2D CAD vs 3D CAD depends on the project’s requirements, as both have their advantages and limitations. This blog will delve into the differences between 2D CAD vs 3D CAD, helping to clarify when and why each might be used.

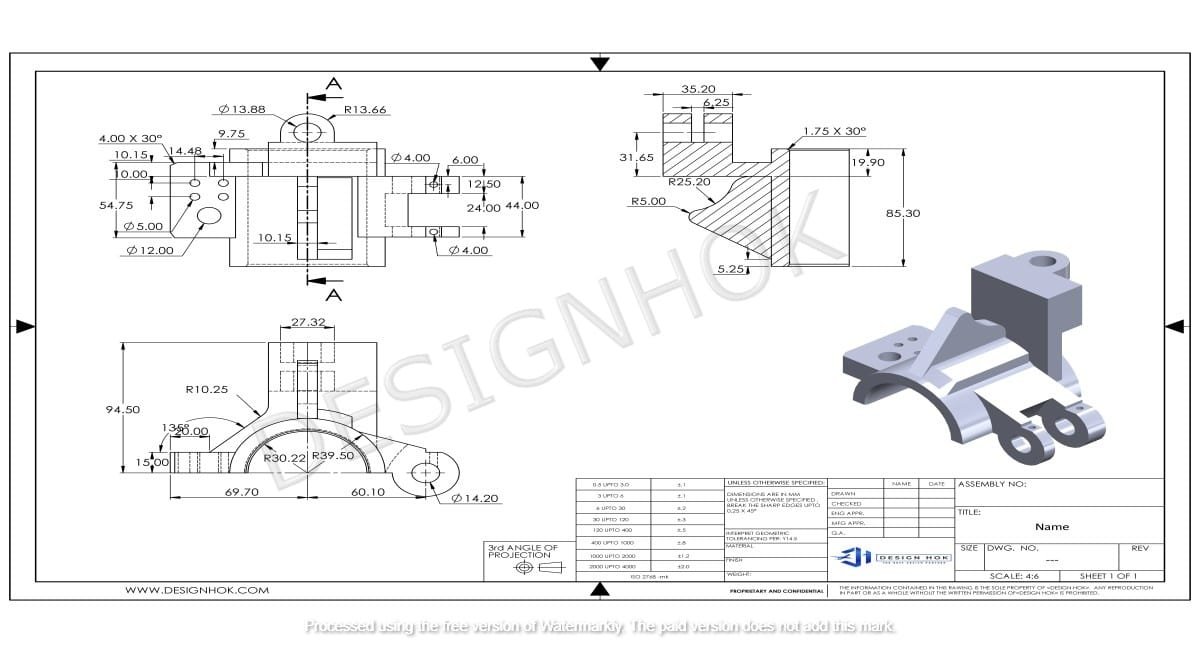

What is 2D CAD?

2D CAD, or two-dimensional computer-aided design, represents objects and structures in two dimensions: height and width. This traditional form of CAD has been around since the early days of digital design tools. In 2D CAD, objects are drawn using lines, curves, and shapes, creating a flat, two-dimensional representation of the design. Although it may seem limited in comparison to 3D modeling, 2D CAD is still widely used for drafting, technical drawings, and floor plans.

Advantages of 2D CAD:

- Simplicity:

- 2D CAD is easier to learn and use, especially for simpler designs and schematic representations. For engineers and designers who primarily need technical drawings, 2D CAD offers an efficient solution.

- Faster for Basic Designs:

- When working with designs that don’t require detailed visualizations, 2D CAD vs 3D CAD can be quicker and more efficient. It’s ideal for projects that only need basic drafting and layouts, such as architectural blueprints or initial sketches.

- Lower Cost:

- 2D CAD software typically costs less than 3D CAD, both in terms of licensing and training. It also requires less processing power from computers, making it more accessible for teams with limited resources.

- Compatibility:

- 2D CAD files are often compatible with older software and systems, which is useful when working with legacy projects or collaborating with external teams using outdated technology.

What is 3D CAD?

3D CAD, or three-dimensional computer-aided design, allows designers to create models with depth, along with height and width. Unlike 2D CAD, 3D modeling enables the visualization of objects in three dimensions, giving a more complete and realistic view of the design. 3D CAD is widely used in industries such as automotive, aerospace, and product development, where complex designs need to be fully visualized before production.

Advantages of 3D CAD:

- Enhanced Visualization:

- 3D CAD provides a realistic representation of the design, allowing engineers to view it from all angles. This helps in better understanding how different components interact and ensures the design functions as intended.

- Improved Accuracy:

- With 3D CAD, designers can create highly accurate models, reducing the risk of errors during the production process. It’s easier to spot potential design flaws and make adjustments before moving to manufacturing.

- Simulation and Testing:

- 3D CAD software often includes simulation tools that allow engineers to test their designs virtually. This is especially valuable for stress testing, thermal analysis, and motion simulation, reducing the need for multiple physical prototypes.

- Collaboration and Communication:

- 3D models are easier to share and understand, especially for stakeholders who may not have technical expertise. This makes it easier for teams to collaborate and for clients to visualize the end product.

Key Differences Between 2D CAD vs 3D CAD

- Design Perspective:

- 2D CAD is flat and offers only two dimensions (height and width), whereas 3D CAD allows for depth, creating more lifelike models that can be viewed from any angle.

- Complexity:

- 2D CAD is more suited for simpler designs or when only basic technical drawings are needed. 3D CAD, on the other hand, is ideal for complex designs requiring detailed visualization and interaction between parts.

- Accuracy and Precision:

- 3D CAD provides greater precision as it allows for real-world simulations and exact measurements, reducing design flaws. 2D CAD, while accurate for technical drawings, may lead to discrepancies when translating to physical models.

- Ease of Use:

- 2D CAD is typically easier to learn and faster to use for simple designs, whereas 3D CAD requires more expertise and can be more time-consuming due to its complexity.

- Cost and Resources:

- 2D CAD is generally less expensive in terms of software and hardware requirements. 3D CAD tends to require more powerful computers and more costly software, but it also provides more advanced capabilities.

- Application Areas:

- 2D CAD is often used for schematic designs, floor plans, and simple drafting. 3D CAD is used in industries that need full-scale models, including automotive, aerospace, and product development.

Design Hok Approach to 2D CAD vs 3D CAD

At Design Hok, both 2D CAD vs 3D CAD are used depending on the project’s requirements. For projects involving complex parts, mechanical systems, or where visualization is critical, 2D CAD vs 3D CAD is the preferred tool. It enables the team to create accurate, detailed models that can be tested and optimized before production.

However, for simpler drafting needs, initial design layouts, or when working with legacy projects, 2D CAD is still a valuable tool. By using a combination of both 2D CAD vs 3D CAD, Design Hok ensures flexibility and efficiency in tackling a wide range of design challenges.

Conclusion:

Choosing Between 2D CAD vs 3D CAD

Understanding the differences between 2D CAD vs 3D CAD is crucial for selecting the right tool for a project. While 2D CAD remains a reliable and efficient choice for simple designs and technical drawings, 3D CAD offers a more comprehensive approach with enhanced visualization, accuracy, and simulation capabilities. At Design Hok, the team leverages both types of CAD to deliver high-quality, innovative solutions tailored to the specific needs of each project.

FAQs

1. What is the main difference between 2D CAD vs 3D CAD?

The main difference is that 2D CAD provides a flat, two-dimensional representation of designs (height and width), while 3D CAD adds depth, creating three-dimensional models that offer more realistic visualization.

2. When should I use 2D CAD?

2D CAD is best for simpler projects, technical drawings, floor plans, and initial sketches where detailed visualization is not required.

3. What are the benefits of using 3D CAD?

3D CAD provides enhanced visualization, greater accuracy, the ability to test and simulate designs, and improved collaboration by offering a lifelike model that can be viewed from any angle.

4. Is 3D CAD more expensive than 2D CAD?

Yes, 3D CAD generally requires more powerful software and hardware, making it more costly than 2D CAD. However, its advanced capabilities can lead to more efficient and accurate design processes.

5. Can I convert a 2D CAD drawing into a 3D model?

Yes, most CAD software allows for the conversion of 2D drawings into 3D models. This can help transition from simple drafts to more detailed designs as the project progresses.

6. Which industries typically use 3D CAD over 2D CAD?

Industries like automotive, aerospace, manufacturing, and product development often use 3D CAD for its ability to handle complex designs, precise measurements, and simulations.

7. Does Design Hok use both 2D CAD vs 3D CAD?

Yes, Design Hok uses both 2D and 3D CAD depending on the project’s requirements. 2D CAD is utilized for simpler drafting needs, while 3D CAD is employed for more complex designs that require detailed visualization and simulation.