3D Over 2D CAD Drafting for Design Hok can leverage these benefits to improve product development, accuracy, and collaboration.

Introduction:

Moving from 3D Over 2D CAD Drafting for Design Hok

Computer-Aided Design (CAD) has revolutionized the way engineers, architects, and designers create and refine their ideas. For many years, 3D Over 2D CAD Drafting for Design Hok was the standard, offering a digital way to create technical drawings with precision. However, with the advancement of technology, 3D Over 2D CAD Drafting for Design Hok drafting has become a powerful tool, offering enhanced capabilities that far surpass the limitations of 2D. In industries like mechanical engineering and product development, 3D CAD has opened new avenues for innovation and efficiency. For companies like Design Hok, adopting 3D over 2D CAD can significantly enhance the design process, improving precision, visualization, and collaboration.

we’ll explore the key advantages of 3D CAD drafting over 2D CAD, and why companies like Design Hok should consider fully embracing 3D CAD in their projects.

1. Enhanced Visualization and Realistic Representation

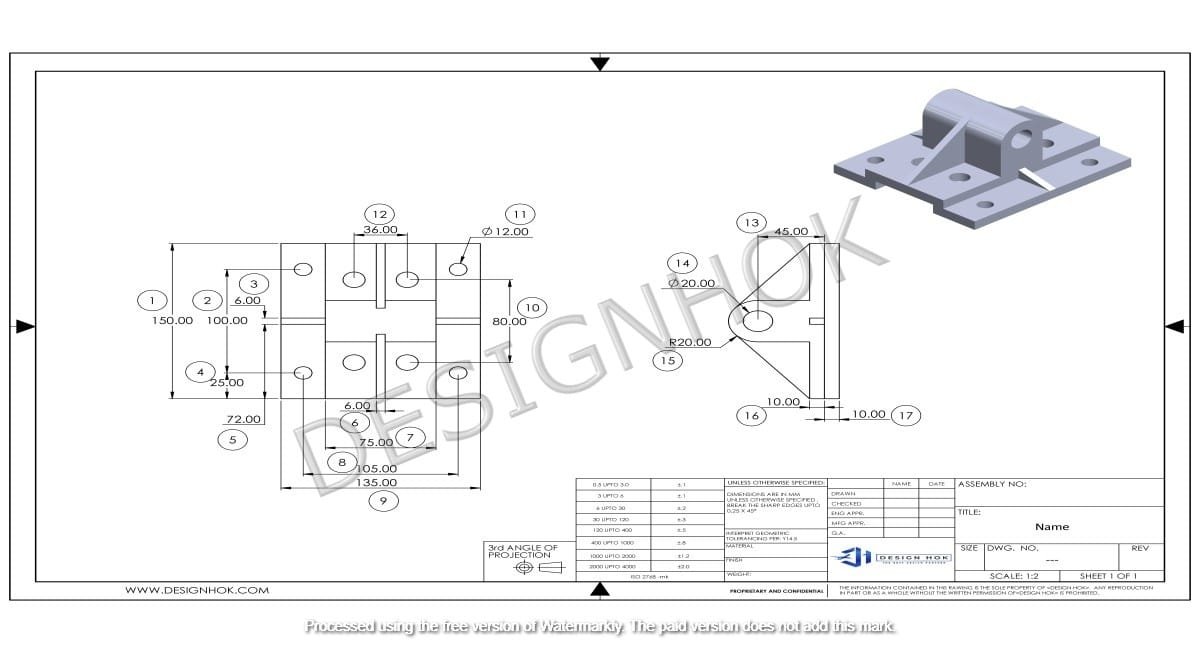

One of the most obvious advantages of 3D CAD over 2D CAD is the ability to create realistic, three-dimensional representations of designs. In 3D Over 2D CAD Drafting for Design Hok, designers can only view the design from specific angles or in flat views (top, front, side), limiting the overall understanding of how the product or system will look and function.

With 3D CAD, designers can view the model from all angles, offering a complete and immersive visualization. This not only helps designers understand the spatial relationships between components but also allows stakeholders and clients to grasp the design concept more easily. For Design Hok, this means fewer misunderstandings and more precise communication with clients and team members.

2. Improved Design Accuracy and Error Detection

In 2D drafting, errors such as misalignment, incorrect dimensions, or interference between components can easily go unnoticed. These mistakes often aren’t identified until the later stages of the project, leading to costly revisions or redesigns.

With 3D Over 2D CAD Drafting for Design Hok, the risk of these errors is greatly reduced. 3D modeling tools can automatically detect issues like component interferences, misalignments, or unrealistic assembly constraints. The ability to simulate real-world conditions in 3D allows Design Hok to spot and correct potential design flaws early in the process, reducing the likelihood of expensive changes later in development.

3. Faster Prototyping and Testing Through Simulation

3D Over 2D CAD Drafting for Design Hok allows for seamless integration with various simulation tools. These tools enable engineers and designers to test the performance of their designs under different conditions—such as stress, heat, and motion—before creating physical prototypes. This capability is not possible with 2D drafting, which relies solely on flat representations that cannot be tested in the same way.

For Design Hok, this means quicker validation of design concepts, more iterations in less time, and a significant reduction in the need for physical prototypes. As a result, time-to-market can be shortened, and product development costs can be minimized.

Efficient Collaboration and Communication

Another key advantage of 3D Over 2D CAD Drafting for Design Hok is the ease with which it allows teams to collaborate. In 3D Over 2D CAD Drafting for Design Hok, communicating design intent can be difficult, as team members and stakeholders have to interpret flat drawings. Different team members may interpret dimensions or layouts in slightly different ways, leading to confusion or errors.

With 3D models, everyone can see the same design in its full, three-dimensional form. This ensures that the entire team—including designers, engineers, project managers, and clients—are on the same page. Changes can be made and reviewed in real-time, allowing for smoother collaboration and fewer miscommunications.

For Design Hok, the ability to present 3D models during design reviews can lead to quicker approvals, better feedback, and improved overall project efficiency.

Better Documentation and Detail Extraction

While 3D Over 2D CAD Drafting for Design Hok is commonly used for creating technical drawings and blueprints, 3D CAD takes it a step further by allowing the automatic generation of 2D drawings from 3D models. This not only saves time but also ensures that the drawings are consistent with the final design.

Moreover, 3D models contain far more detail than 2D drafts. Designers can easily extract detailed views, cross-sections, and exploded diagrams, providing a clearer understanding of the design. For Design Hok, this level of detail is invaluable when creating technical documents, assembly instructions, or marketing materials.

More Efficient Design Modifications and Updates

One of the challenges of using 3D Over 2D CAD Drafting for Design Hok is the time it takes to make changes to a design. If a component needs to be modified, the designer must manually update every drawing that contains that component, which is time-consuming and increases the risk of mistakes.

With 3D CAD, changes can be made to the 3D model, and these changes will automatically update across all related views and documents. This saves considerable time and ensures that all aspects of the design remain synchronized. For Design Hok, this means faster iterations and the ability to respond to changes or client feedback more efficiently.

Advanced Manufacturing Integration

Modern manufacturing methods, such as CNC machining and 3D printing, are increasingly reliant on 3D CAD models for their operations. These processes require precise, detailed models that can be directly imported into manufacturing software to ensure accuracy during production.

For Design Hok, using 3D Over 2D CAD Drafting for Design Hok ensures that designs are production-ready and can be smoothly transitioned from the digital realm to physical manufacturing. This reduces the risk of errors during the manufacturing process and ensures that the final product closely matches the design intent.

ts. Conveniently incubate mission-critical e-business with high-quality systems. Interactively provide access to open-source e-business without compelling e-markets. Intrinsically visualize user-centric meta-services after vertical e-business

Conclusion:

Embracing 3D Over 2D CAD Drafting for Design Hok Future

The transition from 2D to 3D CAD drafting offers numerous advantages that can significantly enhance the design and development process for companies like Design Hok. From improved visualization and collaboration to faster prototyping and reduced errors, 3D CAD opens up new possibilities for innovation and efficiency. By fully embracing 3D drafting tools, Design Hok can stay ahead of the competition, delivering better products with greater precision and speed.

FAQs

1. What is the main difference between 2D and 3D CAD?

2D CAD focuses on flat, two-dimensional drawings from specific perspectives, while 3D CAD creates fully interactive three-dimensional models that can be viewed and manipulated from any angle.

2. How does 3D CAD improve design accuracy?

3D CAD allows for automatic detection of issues like component misalignment or interference, helping designers spot errors before they become costly problems during production.

3. Can 3D CAD reduce the need for physical prototypes?

Yes, 3D CAD integrates with simulation tools that enable virtual testing of designs, reducing the number of physical prototypes needed and saving time and money.

4. How does 3D CAD support collaboration in design projects?

3D models provide a clear, realistic representation of the design, making it easier for teams and stakeholders to understand and communicate design intent, ensuring everyone is on the same page.

5. What industries benefit from using 3D CAD?

Industries such as automotive, aerospace, construction, manufacturing, and consumer products benefit greatly from the precision, efficiency, and advanced capabilities offered by 3D CAD.