Explore the exceptional 3D modeling services for machine parts offered by Design Hok, where precision, innovation, and efficiency are combined to bring cutting-edge engineering solutions to life.

Introduction:

The Importance of 3D Modeling in Machine Part Design

In the ever-evolving world of engineering, the design and development of machine parts have become increasingly complex. Precision, accuracy, and functionality are paramount, making 3D modeling an indispensable tool for engineers and designers. 3D modeling for machine parts in engineering allows for the visualization, simulation, and refinement of complex components before they are physically produced. At Design Hok, our 3D modeling services provide a comprehensive solution that enables clients to achieve high-quality, functional machine parts while reducing production costs and timelines.

What is 3D Modeling Services for Machine Parts?

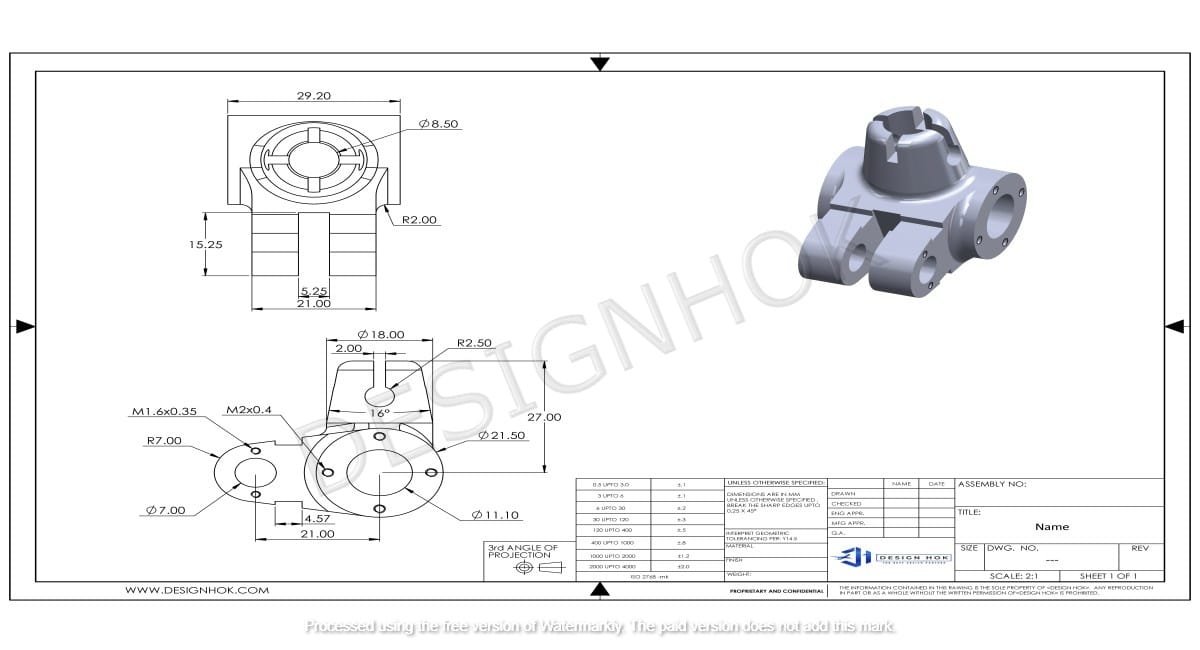

3D modeling for machine parts involves the use of specialized software to create detailed, three-dimensional digital representations of mechanical components. These models serve as blueprints, allowing engineers to test the design, visualize its interactions with other parts, and make necessary adjustments before moving to physical production. This process not only ensures accuracy but also helps to identify potential design flaws early on.

3D Modeling Services for Machine Parts is particularly beneficial for the design and production of complex machine parts, such as gears, engines, and precision components, where every detail matters. By creating a digital model, engineers can simulate how the part will function under various conditions, ensuring it meets performance and safety requirements.

The Role of 3D Modeling in Machine Part Design at Design Hok

At Design Hok, we utilize state-of-the-art 3D Modeling Services for Machine Parts technology to provide top-tier engineering services for machine part design. Our approach emphasizes innovation, precision, and efficiency, ensuring that every part we design meets the highest standards of quality. Here’s how 3D modeling plays a crucial role in our process:

1. Visualization and Detailed Representation

One of the primary advantages of 3D Modeling Services for Machine Parts is its ability to create highly detailed, accurate visual representations of machine parts. These models allow both our engineering team and clients to see exactly how each component will look and function before it is manufactured. This level of detail is essential for ensuring that the part will meet its intended purpose and fit seamlessly into the larger system.

With 3D modeling, we can provide clients with a clear visual of how the machine part will function, offering them an opportunity to request modifications or improvements before the manufacturing phase.

2. Precision Engineering and Accuracy

The importance of precision in engineering cannot be overstated, especially when it comes to machine parts that must meet specific performance criteria. 3D Modeling Services for Machine Parts allows for precise control over dimensions, tolerances, and materials, ensuring that each part is designed to exact specifications. This reduces the risk of errors in production, minimizes waste, and ensures that the final product performs as expected.

At Design Hok, our 3D Modeling Services for Machine Parts incorporate advanced parametric modeling, which allows us to adjust and refine designs with precision. Whether we’re designing a simple gear or a complex mechanical system, we ensure that every detail is accounted for.

3. Design Flexibility and Iteration

3D Modeling Services for Machine Parts enables engineers to quickly modify and iterate on designs, making it easier to explore different configurations and optimize performance. This flexibility is crucial in the early stages of machine part design, where small changes can have a significant impact on the overall function of the component.

Design Hok uses 3D modeling to test various design options, allowing us to identify the most efficient and effective solutions. This iterative process also helps to reduce development time and cost, as potential issues can be addressed in the digital model before physical prototypes are created.

4. Simulation and Performance Testing

Before a machine part is manufactured, it’s important to know how it will perform under real-world conditions. 3D modeling software allows us to run simulations that test the part’s performance, durability, and stress tolerance. These simulations can mimic various operating conditions, such as load, heat, and wear, providing valuable insights into how the part will behave.

At Design Hok, we use these simulations to optimize machine parts for durability, efficiency, and safety. By identifying potential weaknesses in the design, we can make adjustments that improve the part’s overall performance, ensuring it will meet the client’s needs.

5. Cost-Effective Prototyping and Production

Physical prototyping can be expensive and time-consuming, especially when multiple iterations are required to get the design right. With 3D Modeling Services for Machine Parts, we can create virtual prototypes that allow for comprehensive testing and refinement without the need for costly physical prototypes.

Design Hok leverages 3D modeling to streamline the prototyping process, reducing costs and accelerating time-to-market. Once the design is finalized in the digital model, we provide clients with detailed manufacturing plans, ensuring that the production process is as efficient and cost-effective as possible.

Key 3D Modeling Services for Machine Parts

Design Hok provides a wide range of 3D modeling services for machine parts, each tailored to meet the unique needs of our clients. Here are some of the core services we offer:

1. Custom Part Design

We specialize in designing custom machine parts that are tailored to specific applications. Whether it’s a component for a new machine or a replacement part for an existing system, our 3D Modeling Services for Machine Parts ensure that the part will meet all technical and functional requirements.

2. Reverse Engineering

For clients looking to replicate or improve existing machine parts, we offer reverse engineering services. Using advanced 3D Modeling Services for Machine Parts techniques, we can create detailed models of existing parts, allowing for accurate reproduction or modification to enhance performance.

3. Assembly Modeling

In addition to individual parts, we also offer assembly modeling services, where we create 3D models of entire mechanical systems. This allows clients to see how different components fit together and interact, ensuring proper function and compatibility.

4. Simulation and Analysis

Our 3D Modeling Services for Machine Parts include simulation and analysis, allowing us to test how parts will perform under various conditions. This includes stress analysis, thermal analysis, and motion studies, all of which help to optimize the design for performance and durability.

5. Manufacturing Support

Once the design is finalized, we provide detailed manufacturing plans and specifications to ensure that the part can be produced accurately and efficiently. Our 3D Modeling Services for Machine Parts serve as a blueprint for manufacturers, reducing the risk of errors during production.

Why Choose Design Hok for 3D Modeling Services for Machine Parts?

Design Hok is committed to delivering high-quality, innovative solutions for machine part design. Here’s why clients choose us for their 3D modeling needs:

- Expertise: Our team of experienced engineers and designers has extensive knowledge in 3D Modeling Services for Machine Parts and machine part design, ensuring that every project is handled with precision and care.

- Cutting-Edge Technology: We use the latest 3D Modeling Services for Machine Parts software and tools to create detailed, accurate models that meet the highest industry standards.

- Customized Solutions: We work closely with clients to understand their specific needs and provide tailored solutions that meet their unique requirements.

- Efficiency: Our 3D modeling services streamline the design process, reducing time and cost while maintaining high levels of accuracy and quality.

- Collaboration: We believe in open communication and collaboration with our clients, ensuring that they are involved in every step of the design process.

Conclusion:

The Future of Machine Part Design with 3D Modeling

3D Modeling Services for Machine Parts has revolutionized the way machine parts are designed and produced. At Design Hok, we are proud to offer comprehensive 3D Modeling Services for Machine Parts that help our clients bring their ideas to life with precision, efficiency, and innovation. Whether you’re developing a new machine part or improving an existing one, our 3D modeling services provide the tools you need to succeed.

FAQs

1. What is 3D Modeling Services for Machine Parts?

3D modeling for machine parts is the process of creating detailed, digital representations of mechanical components using specialized software. These models help engineers visualize, test, and refine designs before production.

2. How does 3D modeling improve machine part design?

3D modeling improves machine part design by providing precision, allowing for design iteration, enabling simulations, and reducing the need for physical prototypes. This results in more accurate, cost-effective, and efficient designs.

3. What software does Design Hok use for 3D modeling?

Design Hok uses industry-leading 3D modeling software such as SolidWorks, AutoCAD, and CATIA to create detailed and accurate models of machine parts.

4. How do simulations in 3D modeling help in the design process?

Simulations allow engineers to test how the machine part will perform under various conditions, such as stress and heat. This helps to identify and address potential issues before production, ensuring the part meets performance standards.

5. Can Design Hok help with reverse engineering machine parts?

Yes, Design Hok offers reverse engineering services, allowing us to create detailed 3D models of existing machine parts for replication or improvement.

6. How does 3D modeling save time and money?

3D modeling reduces the need for multiple physical prototypes, allowing for quicker design iterations and identifying design flaws early. This helps reduce development costs and accelerates the production process.