Understanding 3D Modeling and CAD in Design Hok: A Comprehensive Guide

Understanding 3D Modeling and CAD in Design Hok: A Comprehensive GuideUnderstanding 3D Modeling and CAD in Design Hok: A Comprehensive Guide

Introduction:

The Fusion of Creativity and Technology in Design

In the modern world of design and engineering, the convergence of technology and creativity has reshaped how products, structures, and systems are developed. 3D modeling and Computer-Aided Design (CAD) are at the heart of this revolution, allowing designers and engineers to bring their ideas to life with remarkable precision and efficiency. For companies like Design Hok, these tools are indispensable in delivering cutting-edge designs across various industries. In this blog, we’ll explore what 3D Modeling and CAD in Design Hok is, its significance in design projects, and how Design Hok harnesses this technology to achieve outstanding results.

What is 3D Modeling and CAD in Design Hok?

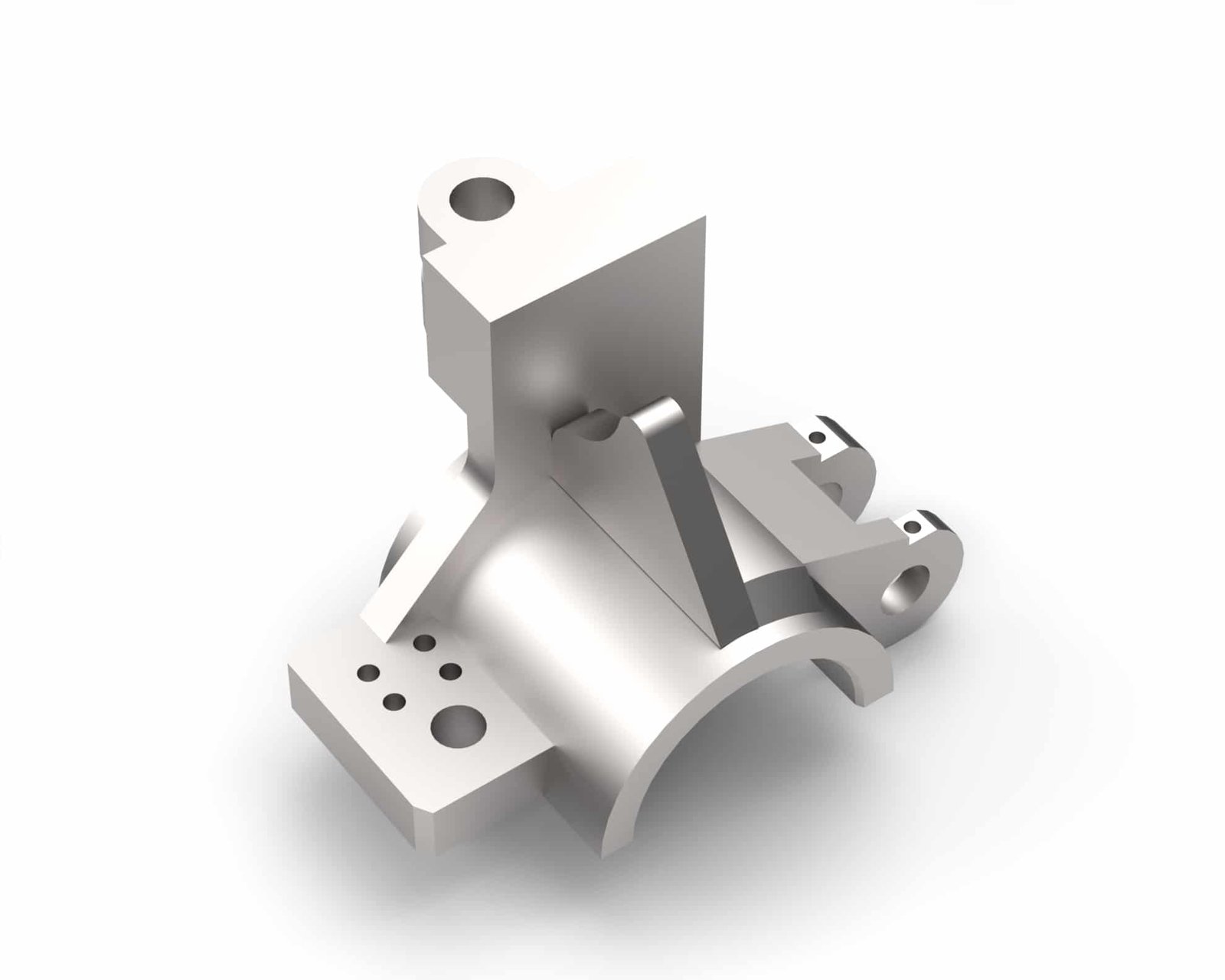

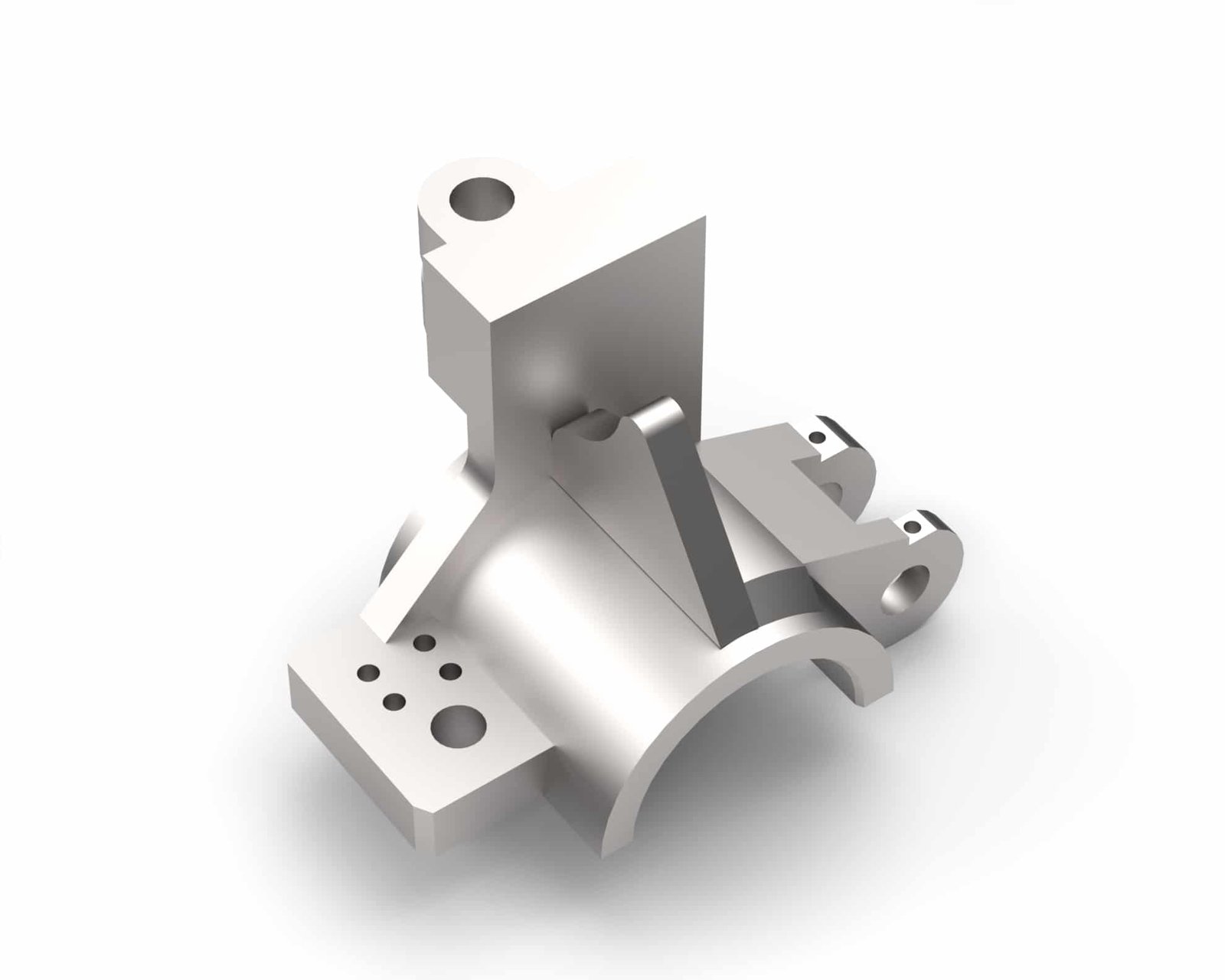

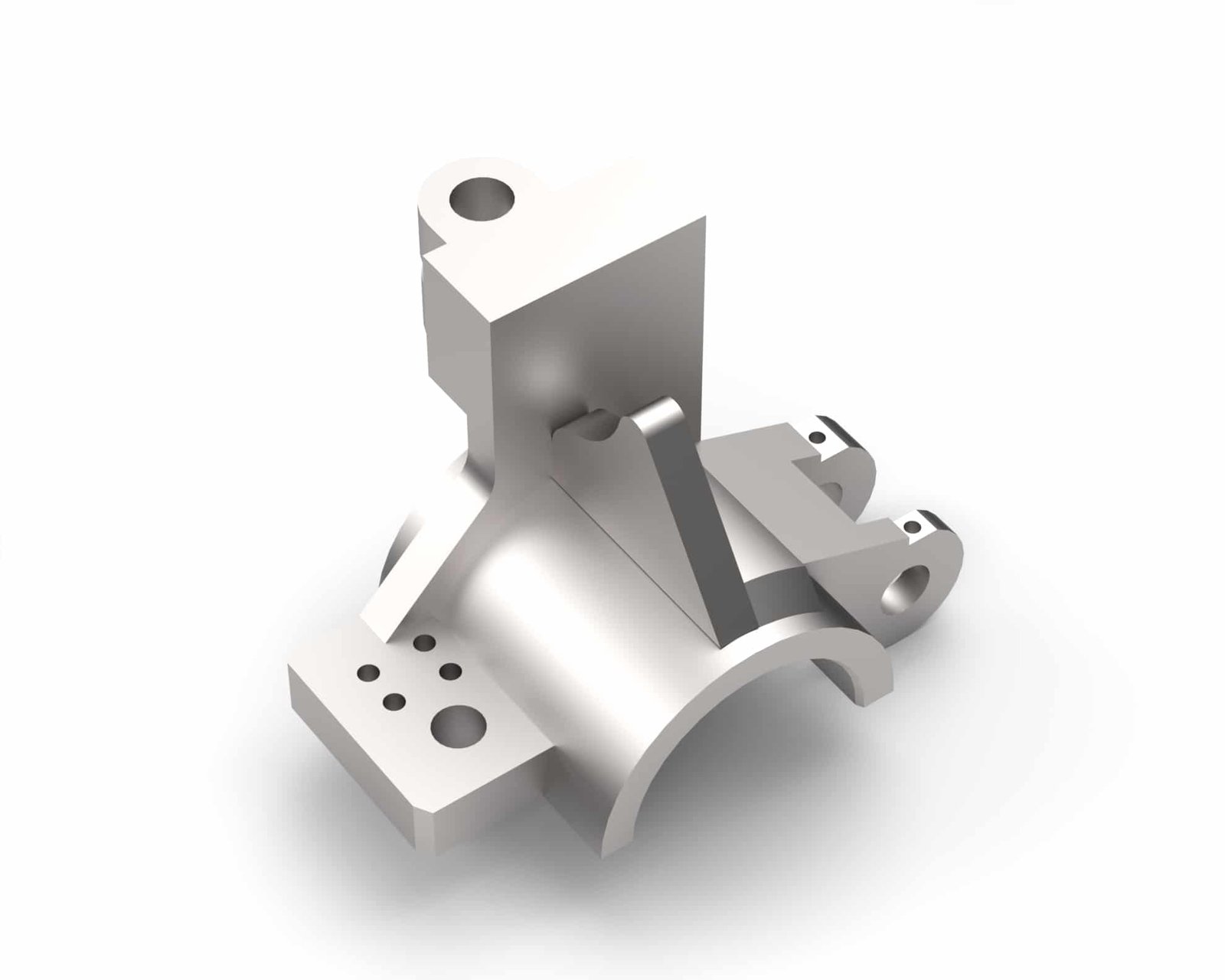

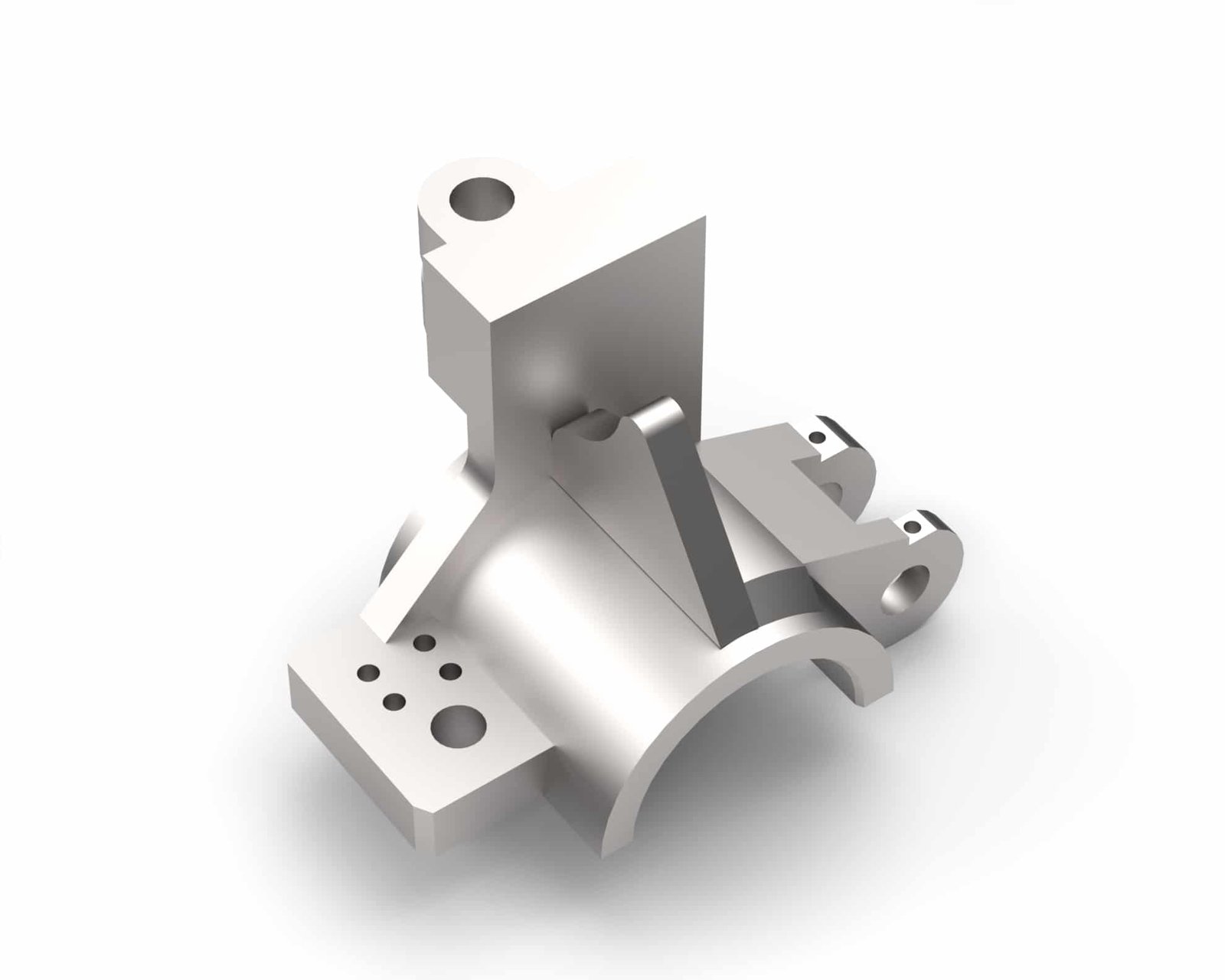

3D modeling refers to the process of creating a three-dimensional representation of an object using specialized software. This digital representation can mimic real-world objects, systems, or designs, enabling designers and engineers to see how their creations will look and function in the physical world. CAD, or Computer-Aided Design, is the technology that facilitates the creation, modification, and optimization of these 3D models. CAD software helps designers and engineers develop precise models that can be used for analysis, testing, and manufacturing.

3D Modeling CAD is, therefore, a combination of these two powerful tools: it allows for the creation of detailed and accurate 3D Modeling and CAD in Design Hok using CAD software, enabling a seamless transition from concept to production.

How Does 3D Modeling and CAD in Design Hok Work?

The process of 3D modeling CAD involves several key steps, each contributing to the creation of an accurate and functional design:

Conceptualization:

The designer begins with a concept or idea for a product, part, or system. Initial sketches, diagrams, and notes may be created to outline the main features and functionalities.Model Creation:

Using CAD software, the designer then creates a 3D model of the object. This process involves defining the shape, size, and dimensions of the object. The designer can manipulate the model in three dimensions, ensuring that every detail is captured.Simulation and Testing:

Once the model is complete, it can be subjected to simulations to test how it will perform under different conditions. This includes stress testing, motion analysis, and thermal simulations, all conducted within the CAD software.Design Optimization:

Based on the results of the simulations, the model can be modified and optimized to improve its performance. This iterative process ensures that the final design is as efficient and functional as possible.Finalization and Documentation:

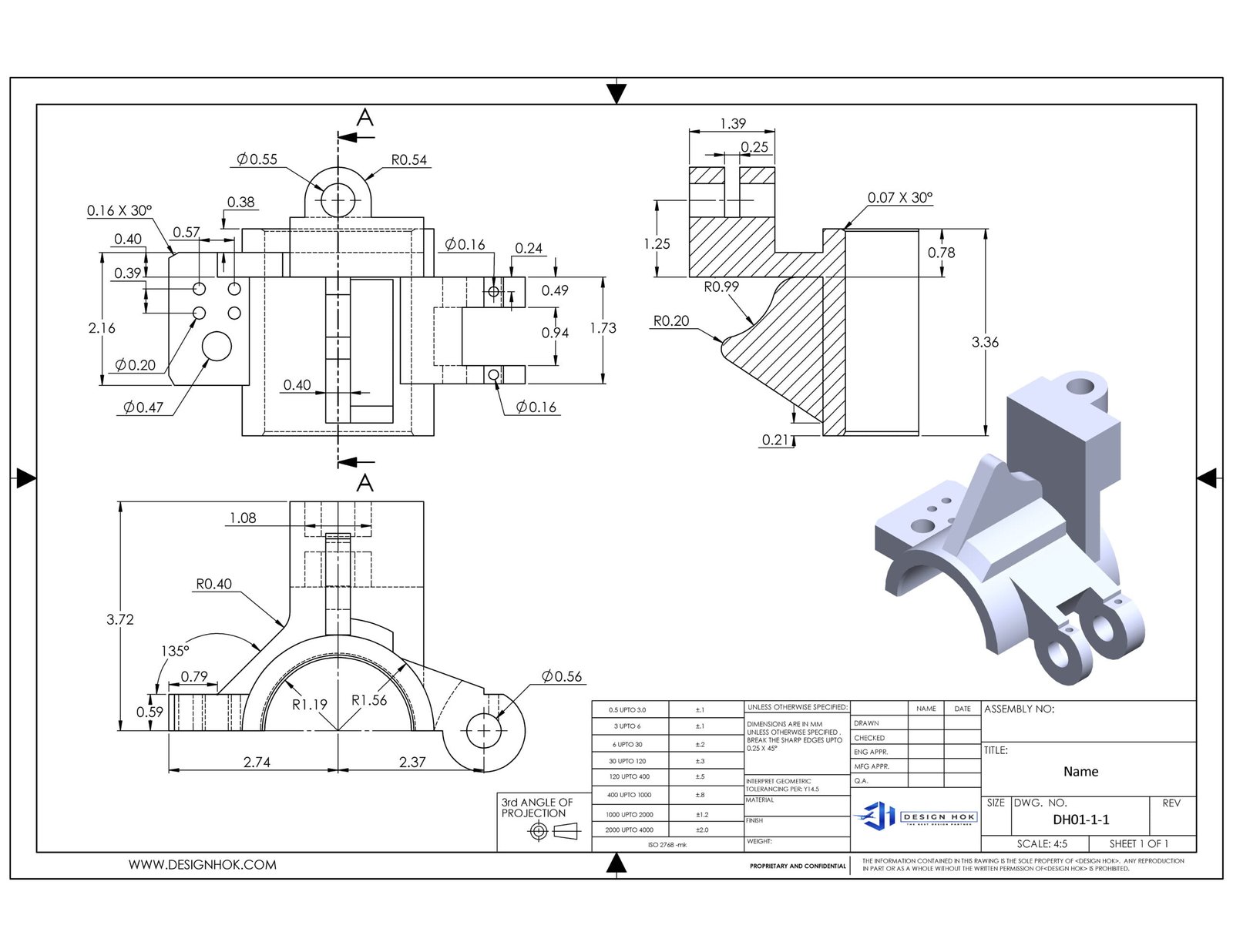

After the design is optimized, detailed technical drawings and specifications are generated from the 3D Modeling and CAD in Design Hok. These documents serve as a blueprint for manufacturing the object and include all the necessary dimensions, materials, and tolerances.

The Role of 3D Modeling and CAD in Design Hok

At Design Hok, 3D modeling CAD is integral to every stage of the design process. Whether the team is working on an industrial machine, consumer product, or architectural structure, CAD technology enables them to achieve greater accuracy, innovation, and efficiency. Below are some key ways in which Design Hok leverages 3D modeling CAD:

1. Enhancing Visualization

3D modeling CAD allows Design Hok to visualize projects in a way that traditional 2D drawings cannot. With a three-dimensional model, designers and clients alike can see the product from all angles, making it easier to understand its form and function. This is especially useful in complex projects where understanding the spatial relationships between components is crucial.

2. Improving Accuracy and Precision

One of the biggest advantages of CAD software is the level of precision it offers. Every dimension, angle, and curve can be defined with pinpoint accuracy, minimizing the chances of errors during manufacturing. Design Hok uses CAD to ensure that every component fits perfectly, meets all design requirements, and adheres to industry standards.

3. Facilitating Collaboration

In a multidisciplinary environment like Design Hok, collaboration is key to delivering successful projects. 3D modeling CAD makes it easier for different team members—engineers, designers, manufacturers, and clients—to work together. The digital model serves as a central point of reference, ensuring that everyone is aligned and can contribute to the project efficiently.

4. Speeding Up Prototyping

Prototyping is a critical part of the design process, but physical prototypes can be time-consuming and expensive to produce. With 3D modeling CAD, Design Hok can create digital prototypes that can be tested and refined in the software environment before moving to physical production. This speeds up the design process, reduces costs, and allows for faster iterations.

5. Streamlining Manufacturing

When the design is ready for production, the CAD model can be used to generate detailed manufacturing instructions. These include technical drawings, assembly instructions, and machine-readable data for CNC machines or 3D printers. By providing manufacturers with accurate and complete information, Design Hok ensures that the final product is produced to the highest standards.

Benefits of 3D Modeling and CAD in Design Hok

The integration of 3D modeling CAD into Design Hok’s workflow provides a wide range of benefits, both for the company and its clients:

Enhanced Creativity:

3D modeling CAD frees designers to experiment with new shapes, materials, and functions. This opens the door to more innovative solutions that may not have been possible with traditional design methods.Greater Efficiency:

By reducing the need for physical prototypes and speeding up the design iteration process, CAD helps Design Hok deliver projects faster. This efficiency is passed on to clients in the form of shorter lead times and lower costs.Increased Accuracy:

CAD software eliminates much of the guesswork that can lead to errors in the design process. With precise control over every aspect of the design, Design Hok can ensure that the final product meets all specifications and performs as intended.Better Communication:

The ability to visualize designs in 3D improves communication between designers, clients, and manufacturers. Everyone can see exactly what the final product will look like, making it easier to provide feedback and make informed decisions.Cost-Effectiveness:

By catching errors early and streamlining the prototyping process, 3D modeling CAD reduces costs throughout the design and manufacturing process. Design Hok can offer clients high-quality designs at a competitive price.

Examples of 3D Modeling and CAD in Design Hok

Automotive Parts:

Design Hok uses 3D modeling CAD to design complex automotive components, such as engine parts and transmission systems. The precision of CAD ensures that these parts meet strict performance and safety standards.Consumer Electronics:

For consumer electronics, Design Hok uses CAD to create sleek, functional designs that meet both aesthetic and technical requirements. The ability to visualize the product in 3D ensures that the final product will be both visually appealing and functional.Architectural Structures:

In architectural design, CAD allows for the creation of detailed models that include structural components, materials, and lighting. This helps architects and clients understand how the building will look and function before construction begins.

Conclusion:

The Future of 3D Modeling and CAD in Design Hok

As technology continues to evolve, 3D modeling CAD will remain a critical tool for design and engineering. For Design Hok, the integration of this technology allows the company to push the boundaries of creativity while maintaining the highest standards of accuracy and efficiency. Whether developing automotive parts, consumer products, or architectural structures, 3D modeling CAD is the key to turning ideas into reality.

Why Are Mechanical Design Services Essential?

1. Turning Ideas into Reality

The first step in product development is to turn an idea into something tangible. Mechanical design services begin with conceptualizing the product through detailed sketches and 3D models. These models provide a clear vision of what the product will look like and how it will function. Creating prototypes from these models allows designers to test the product early on, identifying and fixing any issues before full-scale production begins.

2. Optimizing for Manufacturing

Designing a product isn’t just about how it will look or work—it’s also about how it will be made. Mechanical design services focus on making the product easy to manufacture. This means selecting the right materials, designing parts that fit together easily, and ensuring that the manufacturing process is cost-effective. By optimizing the design for manufacturing, companies can reduce waste, lower production costs, and speed up the time it takes to bring a product to market.

3. Ensuring Product Performance

For a product to be successful, it needs to perform reliably in the real world. Mechanical design services include rigorous testing and analysis to ensure that the product can withstand various stresses and conditions. Engineers simulate how the product will behave under different loads, temperatures, and environments. This testing helps to ensure that the final product is durable, reliable, and capable of meeting customer expectations.

4. Meeting Industry Standards

Every industry has specific standards and regulations that products must meet. Whether it’s safety standards, environmental regulations, or quality certifications, mechanical design services ensure that a product complies with all relevant requirements. Meeting these standards is not just about avoiding legal issues—it also helps build trust with customers and sets the product apart from the competition.

5. Reducing Costs and Time to Market

Efficiency is key in today’s fast-paced market. By optimizing the design for manufacturing and reducing the need for costly revisions, mechanical design services can significantly cut down on production costs and time to market. This allows companies to stay competitive and respond quickly to market demands.

The Long-Term Benefits of Mechanical Design

Investing in quality mechanical design services can have long-term benefits for a company. A well-designed product not only performs better but also tends to have a longer lifespan and fewer issues over time. This can lead to higher customer satisfaction, lower return rates, and a stronger reputation for quality. Additionally, a product that is easy and cost-effective to manufacture can lead to higher profit margins and a more successful business overall.

Conclusion

Product mechanical design services are an essential part of the product development process. They help ensure that a product is not only functional and reliable but also cost-effective and ready for the market. By turning ideas into reality, optimizing manufacturing, ensuring performance, and meeting industry standards, mechanical design services play a vital role in the success of any product.

For companies looking to bring a new product to market, investing in professional mechanical design services is a smart decision that can pay off in the long run.

FAQs

1. What is 3D modeling CAD?

3D modeling CAD refers to the process of creating three-dimensional digital models using specialized CAD software. It allows designers and engineers to visualize, modify, and optimize designs before production.

2. How does CAD improve design accuracy?

CAD software provides precise control over dimensions, tolerances, and materials, ensuring that the final product meets all design specifications and performs as intended.

3. What industries benefit from 3D modeling CAD?

3D modeling CAD is used in various industries, including automotive, aerospace, consumer electronics, architecture, and industrial design. It helps improve design efficiency, accuracy, and innovation across these fields.

4. How does 3D modeling CAD reduce project costs?

By identifying and resolving design issues early, reducing the need for physical prototypes, and speeding up the design iteration process, CAD helps lower overall project costs.

5. How does Design Hok use 3D modeling CAD in its projects?

Design Hok uses 3D modeling CAD for visualization, precision design, prototyping, and manufacturing support. It allows for efficient collaboration between designers, engineers, and clients, ensuring the success of every project.