The roles of mechanical design and analysis at Design HOK, highlighting how these processes contribute to the creation of innovative, reliable, and sustainable building systems. Discover how HOK’s approach ensures that every mechanical component is meticulously designed, thoroughly tested, and perfectly aligned with the overall vision of their architectural projects.

What is Mechanical Design and Analysis for HOK?

In the field of engineering, Mechanical Design and Analysis at HOK play a critical role in developing efficient and reliable systems. At HOK, a renowned global design, architecture, engineering, and planning firm, these processes are essential in creating innovative buildings and infrastructure. But what exactly do mechanical design and analysis entail, especially within a firm like HOK? Let’s break it down in simple terms.

Mechanical Design and analysis: The Blueprint of Innovation

Mechanical Design and Analysis at HOK is the process of turning ideas into tangible products or systems. It’s about creating the parts and systems that make machines, buildings, and other structures work. At HOK, mechanical design involves designing systems such as heating, ventilation, and air conditioning (HVAC), plumbing, fire protection, and other mechanical components that are crucial for the functionality of a building.

The design process starts with understanding the project’s requirements. This involves discussions with architects, engineers, and clients to determine what the system needs to do and any limitations that must be considered. For example, in a large office building, the HVAC system must be designed to maintain comfortable temperatures throughout the year while being energy-efficient and cost-effective.

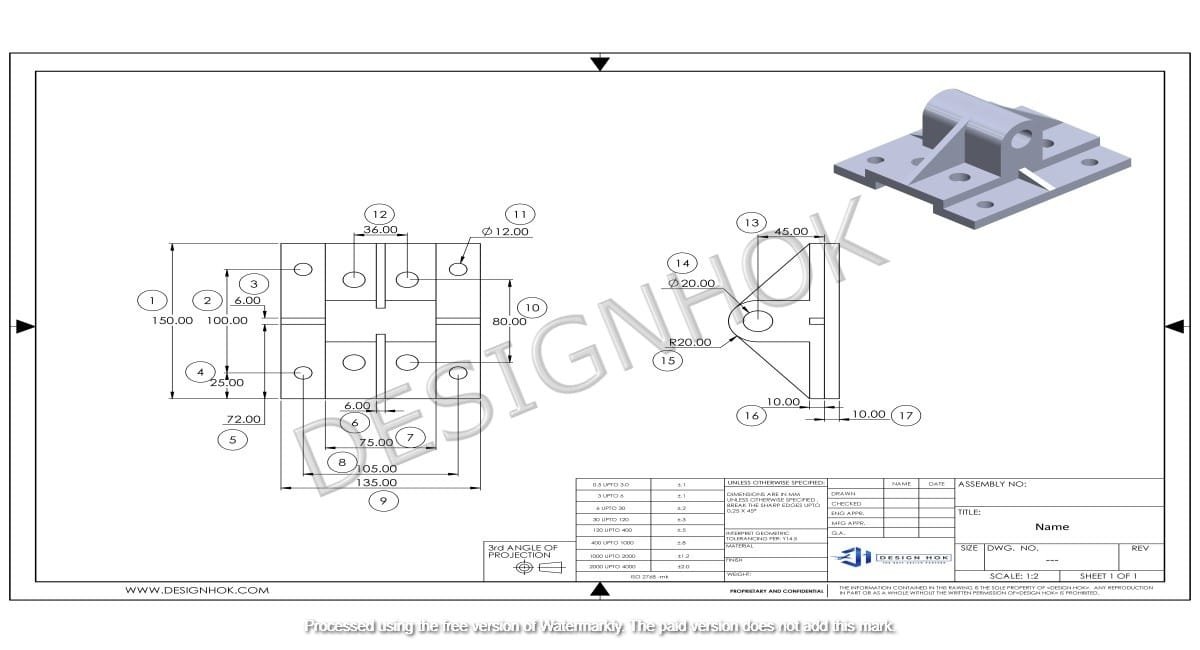

Once the requirements are clear, the Mechanical Design and Analysis at HOK creates initial sketches or models. These models are then developed into detailed designs using Computer-Aided Design (CAD) software. The detailed design includes specifications for materials, dimensions, and the way different parts will fit together. At HOK, the goal is to ensure that these designs are not only functional but also sustainable and aligned with the overall vision of the building.

While Mechanical Design and Analysis at HOK is about creating the blueprint, mechanical analysis is about testing that blueprint to ensure it will work as intended. Mechanical analysis involves evaluating the design to see how it will perform under different conditions, such as stress, temperature changes, and movement.

For instance, in the design of an HVAC system, mechanical analysis might involve simulations to check how well the system will maintain the desired temperature in different parts of the building. Engineers might also analyze how the system will respond to extreme weather conditions or how long it will last before needing maintenance.

Mechanical analysis at HOK helps identify potential problems before the system is built. This could involve finding weak points in the design that could fail under stress or identifying areas where the system could be made more efficient. By conducting thorough analysis, HOK ensures that the mechanical systems in their buildings are safe, reliable, and perform as expected.

How Mechanical Design and Analysis at HOK Work Together

At Mechanical Design and Analysis at HOK are closely linked. The design process often involves multiple iterations, where a design is created, analyzed, and then refined based on the results of the analysis. This iterative process ensures that the final design is optimized for performance, cost, and sustainability.

For example, if the analysis shows that a certain part of the HVAC system is prone to overheating, the design might be adjusted to improve airflow or use different materials that can withstand higher temperatures. This back-and-forth process continues until the design meets all the project’s requirements and passes all necessary tests.

This collaborative approach is one of the reasons why HOK is known for creating buildings that are not only aesthetically pleasing but also highly functional and efficient. The combination of innovative design and rigorous analysis allows HOK to deliver projects that meet the highest standards of quality and performance.

The Importance of Mechanical Design and Analysis at HOK

Mechanical Design and Analysis at HOK are essential to HOK’s ability to create world-class buildings and infrastructure. These processes ensure that the mechanical systems within a building function correctly, are energy-efficient, and meet the needs of the building’s occupants.

Moreover, HOK’s commitment to sustainability means that mechanical design and analysis are not just about making systems that work but also about minimizing environmental impact. By carefully designing and analyzing mechanical systems, HOK can reduce energy consumption, lower emissions, and create buildings that are both comfortable and eco-friendly.

Conclusion

Mechanical Design and Analysis at HOK are at the heart of what makes HOK a leader in the design and engineering industry. These processes allow HOK to transform innovative ideas into practical, reliable, and sustainable solutions. By focusing on both the creation and testing of mechanical systems, HOK ensures that their projects are not only cutting-edge but also built to last.

FAQ: Mechanical Design and Analysis at HOK

1. What is mechanical design?

Mechanical design is the process of creating systems like HVAC, plumbing, and fire protection in buildings. It involves planning, modeling, and detailing to ensure these systems work efficiently and safely.

2. What is mechanical analysis?

Mechanical analysis involves testing and evaluating the mechanical designs to ensure they will perform well under different conditions, such as stress, temperature changes, and movement.

3. How do mechanical design and analysis work together at HOK?

At HOK, mechanical design and analysis are closely linked. The design is created and then analyzed to find potential improvements. This process repeats until the design is optimized for performance, safety, and sustainability.

4. Why are these processes important at HOK?

These processes are crucial because they ensure that the mechanical systems in HOK’s buildings are reliable, energy-efficient, and meet the needs of the occupants while minimizing environmental impact.