Plant Mechanical Design services play a vital role in making industrial plants run smoothly and efficiently. Provides an easy-to-understand overview of these services, explaining what they are, why they are important, and how they can benefit your plant by improving safety, reducing costs, and ensuring everything works together seamlessly. Whether you’re in manufacturing, power generation, or food processing, this guide will help you see the value of investing in good mechanical design for your plant.

Enhancing Your Plant with Mechanical Design Services

In the fast-moving industrial world, efficiency and reliability are crucial. Whether you run a factory, power plant, or processing unit, the performance of your machinery directly affects your success. This is where Plant Mechanical Design come into play. These services focus on designing and optimizing the mechanical systems within your plant to ensure they run smoothly, safely, and efficiently.

What Are Plant Mechanical Design Services?

Plant Mechanical Design services involve creating detailed plans and designs for the mechanical systems in your plant. These systems include everything from pipes and machines to heating, ventilation, and air conditioning (HVAC) systems. The goal is to ensure that all parts of your plant work well together, using minimal energy and reducing downtime. This, in turn, leads to increased productivity and lower operating costs.

Key Elements of Plant Mechanical Design

Phosfluorescently incubate market-driven networks and synergistic e-services. Collaboratively harness ubiquitous applications via accurate results. Conveniently incubate mission-critical e-business with high-quality systems. Interactively provide access to open-source e-business without compelling e-markets. Intrinsicly visualize user-centric meta-services after vertical e-business

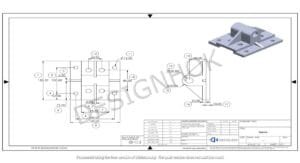

- System Layout: A good design starts with a well-thought-out layout. Plant mechanical design services create detailed blueprints showing where each piece of equipment, pipe, and system should be placed. A smart layout reduces clutter, ensures easy access for maintenance, and maximizes space.

- Piping Design: Piping is essential for transporting fluids and gases throughout your plant. Poorly designed piping can lead to leaks, blockages, and pressure issues. Plant mechanical design services use advanced tools to plan and analyze piping systems, ensuring they are safe, efficient, and suited to the plant’s needs.

- HVAC Design: HVAC systems control the air quality and temperature within your plant. In industries like food processing or pharmaceuticals, maintaining the right environment is crucial. Mechanical design services ensure that HVAC systems are tailored to your plant’s specific requirements, keeping everything at the right temperature and humidity.

- Equipment Design: The machinery in your plant needs to be designed and selected carefully. This includes choosing the right equipment for each task and ensuring that it integrates smoothly with the rest of the plant. Proper equipment design leads to longer machine life, reduced breakdowns, and smoother operation.

- Structural Design: The structure of your plant must support all the mechanical systems. This involves designing strong foundations, supports, and frameworks that can handle the weight and stress of daily operations. A well-designed structure prevents failures and ensures the long-term stability of your plant.

Benefits of Plant Mechanical Design

- Increased Efficiency: Optimizing your plant’s mechanical systems leads to smoother operations. This means less energy is wasted, processes are streamlined, and the overall efficiency of the plant is improved. As a result, you can expect lower energy bills and higher productivity.

- Enhanced Safety: Safety is a key concern in any industrial setting. Proper mechanical design minimizes the risk of accidents and equipment failures. This not only protects your workers but also reduces the chances of costly shutdowns.

- Cost Savings: While investing in mechanical design services requires upfront costs, the long-term savings are significant. Efficient systems lead to lower maintenance costs, reduced energy consumption, and fewer unexpected repairs.

- Flexibility: The industrial landscape is always changing, and your plant needs to be able to adapt. Plant mechanical design services ensure that your systems are flexible enough to accommodate changes in production or new technologies with minimal disruption.

- Regulatory Compliance: Industrial plants must adhere to strict regulations. Mechanical design services ensure that all systems comply with industry standards and legal requirements, reducing the risk of fines and legal issues.

Conclusion

Plant Mechanical Design services are a crucial investment for any industrial operation. By focusing on the detailed planning and optimization of mechanical systems, these services help your plant run more efficiently, safely, and cost-effectively. Whether you are building a new plant or upgrading an existing one, the expertise provided by mechanical design professionals can make a significant difference in the success and longevity of your operations. Investing in these services not only boosts current performance but also prepares your plant for future challenges.

FAQ About Plant Mechanical Design Services

1. What are plant mechanical design services?

These services involve planning and designing the mechanical systems in an industrial plant, like pipes, machines, and ventilation systems, to ensure everything works well together.

2. Why do I need these services?

They help your plant run more efficiently, safely, and at a lower cost by optimizing how everything is set up and operates.

3. Which industries use these services?

Industries like manufacturing, power plants, food processing, and pharmaceuticals often use these services to improve their operations.

4. How can these services improve safety?

Good design reduces the chances of accidents and equipment breakdowns, making your plant safer for workers.

5. Are these services worth the cost?

Yes, because they can save you money in the long run by lowering energy bills, reducing repairs, and keeping your plant running smoothly.