INTRODUCTION:

3D Mechanical Design are transforming product development with cutting-edge three-dimensional modeling. These services provide unparalleled accuracy, efficiency, and insight through detailed visualizations and simulations, enabling faster iterations and cost savings. Embrace the future of engineering with 3D design, and see how it can elevate your projects from concept to reality with precision and innovation.

In the realm of engineering and product development, 3D mechanical design services represent a transformative approach to creating and optimizing mechanical components and systems. By utilizing three-dimensional modeling and simulation, these services offer a powerful way to visualize, test, and refine designs before they reach the manufacturing stage. Here’s a closer look at how 3D mechanical design services are shaping the future of innovation.

What Are 3D Mechanical Design?

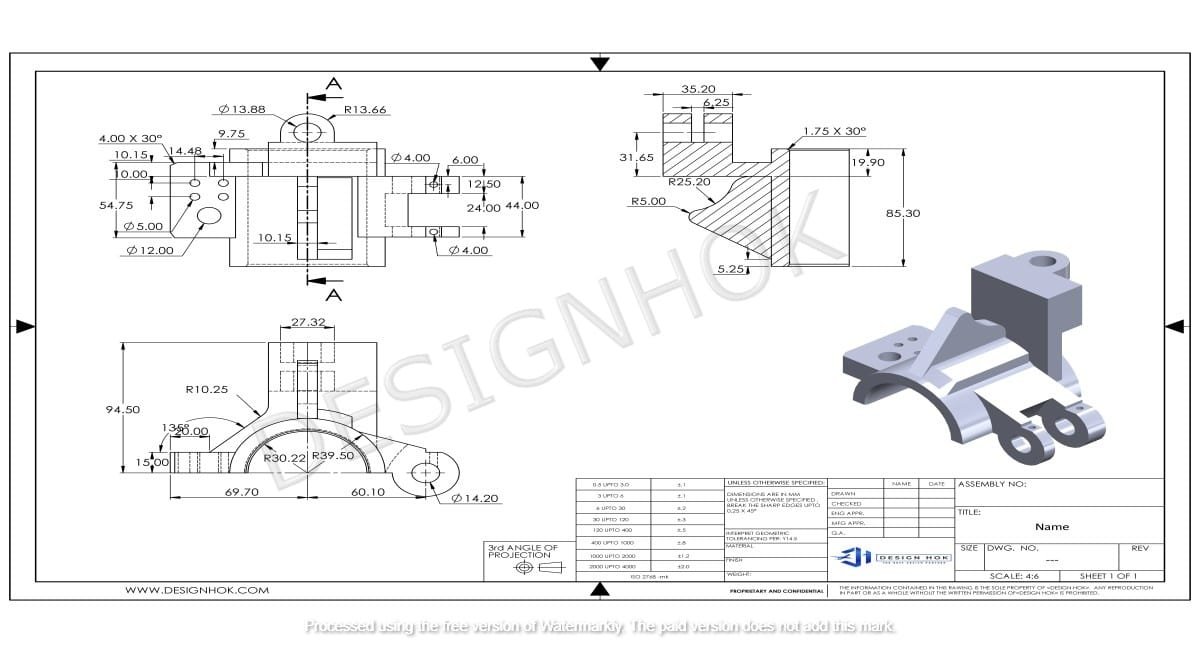

3D Mechanical Design involve the use of advanced computer software to create detailed three-dimensional models of mechanical components and assemblies. These services encompass the entire design process, from initial concept sketches to final, detailed models. The process includes 3D modeling, simulation, analysis, and optimization, ensuring that each component meets specific requirements and integrates seamlessly with other parts.

Key Benefits of 3D Mechanical Design

-

Enhanced Visualization: 3D models provide a clear and accurate representation of how a component or assembly will look and function. This enhanced visualization helps designers and engineers understand the design better, make informed decisions, and communicate ideas effectively with stakeholders.

-

Improved Accuracy and Precision: Traditional 2D drawings can sometimes be ambiguous, leading to errors in interpretation. 3D models eliminate these ambiguities by providing a comprehensive view of the component from all angles. This precision reduces the likelihood of design flaws and manufacturing errors.

-

Efficient Design Iterations: With 3D modeling, engineers can easily modify designs and test different scenarios without needing to create new physical prototypes. This ability to quickly iterate and test designs helps accelerate the development process and allows for more rapid innovation.

-

Enhanced Simulation and Analysis: 3D mechanical design services often include simulation and analysis capabilities. Engineers can use these tools to test how a component will perform under various conditions, such as stress, thermal changes, or vibrations. This predictive analysis helps identify potential issues early and optimize the design for better performance and durability.

-

Cost Savings: By identifying and addressing design issues before manufacturing begins, 3D design services can help reduce costs associated with physical prototyping, rework, and production delays. This cost efficiency is particularly valuable in complex projects where changes can be expensive and time-consuming.

-

Streamlined Communication: 3D models facilitate better communication between designers, engineers, and clients. The visual nature of 3D designs makes it easier to convey ideas and get feedback, ensuring that all parties have a clear understanding of the project’s goals and requirements.

The 3D Mechanical Design

The process of 3D mechanical design typically involves several stages:

-

Conceptual Design: Initial sketches and ideas are developed into basic 3D models. This stage focuses on defining the overall shape, function, and key features of the component.

-

Detailed Design: The basic model is refined with precise dimensions, material specifications, and other details. This stage results in a comprehensive 3D model that is ready for further analysis.

-

Simulation and Analysis: The 3D model is tested using simulation tools to assess its performance under various conditions. This analysis helps identify potential weaknesses and areas for improvement.

-

Prototyping: While physical prototypes may still be used, they are often based on the refined 3D model. Rapid prototyping technologies, such as 3D printing, can be used to create physical models quickly for further testing and validation.

-

Finalization: The design is finalized, and detailed documentation is prepared for manufacturing. This includes specifications, assembly instructions, and other relevant information.

Conclusion

3D Mechanical Design are revolutionizing the way mechanical components and systems are designed and developed. By providing enhanced visualization, precision, and analysis capabilities, these services enable engineers and designers to create more innovative, efficient, and cost-effective solutions. Whether you’re developing new products or refining existing designs, embracing 3D mechanical design services can be a game-changer, paving the way for advancements in technology and manufacturing.

FAQ: 3D Mechanical Design Services

1. What are 3D mechanical design services?

They involve creating detailed 3D models of mechanical parts using advanced software, including modeling, simulation, and optimization.

2. What are the main benefits?

Benefits include better visualization, increased accuracy, faster iterations, cost savings, and improved communication.

3. How does 3D design enhance accuracy?

It provides a complete view of components from all angles, reducing errors compared to 2D designs.

4. What does the process involve?

The process includes conceptual design, detailed modeling, simulation, prototyping, and final documentation.

5. Can these services help reduce costs?

Yes, by identifying issues early and minimizing the need for physical prototypes, they help cut development costs.