Mechanical assemblies make every design with precision. Threaded connections are ways to hold two or more parts together with a screw thread. Depending on how they are made, they can be permanent or removable. The main job of a threaded connection is to hold parts together while still letting them be taken apart when needed. Simply put, a thread is a spiral groove cut into a cylindrical or conical surface. A male thread (like a bolt or screw) fits into a female thread (like a nut or tapped hole). This locks the two parts together and makes a strong mechanical bond.

These connections are used in everything from small consumer goods to big industrial machines like oil rigs, turbines, and aircraft engines. At Design HOK, we provide expert CAD solutions for your business. Our Mechanical assemblies with innovations deliver a proper modelling experience virtually.

Why Threaded Connections Matter

All machine depends on their connections. Machines that were designed poorly or incorrectly can cause problems such as:

- These machines loosen under high pressure.

- It may cause leakage of fluids or gases, which can be very dangerous.

- It causes corrosion between the parts of the machine.

- Overstress leading to fatigue or fracture

- It costs a lot for maintenance or replacement.

Machines that have the right connection mean they have better safety, longer service life, and lower maintenance costs. It also makes sure that these components of the machine can be easily assembled and adjusted.

Basic Components of a Threaded Connection

To master threaded connections, you need to know the key elements that make up the system:

- The main component that provides clamping force is the Bolt or screw.

- Nuts are used to hold the bolt in place, providing the locking mechanism.

- In threaded connection washer helps distribute the load evenly and prevents surface damage.

- The thread form shows the shape, such as metric or UNC/UNF.

- The material of the machine determines strength, corrosion resistance, and thermal behaviour.

Engineers must select each part carefully to ensure compatibility and performance.

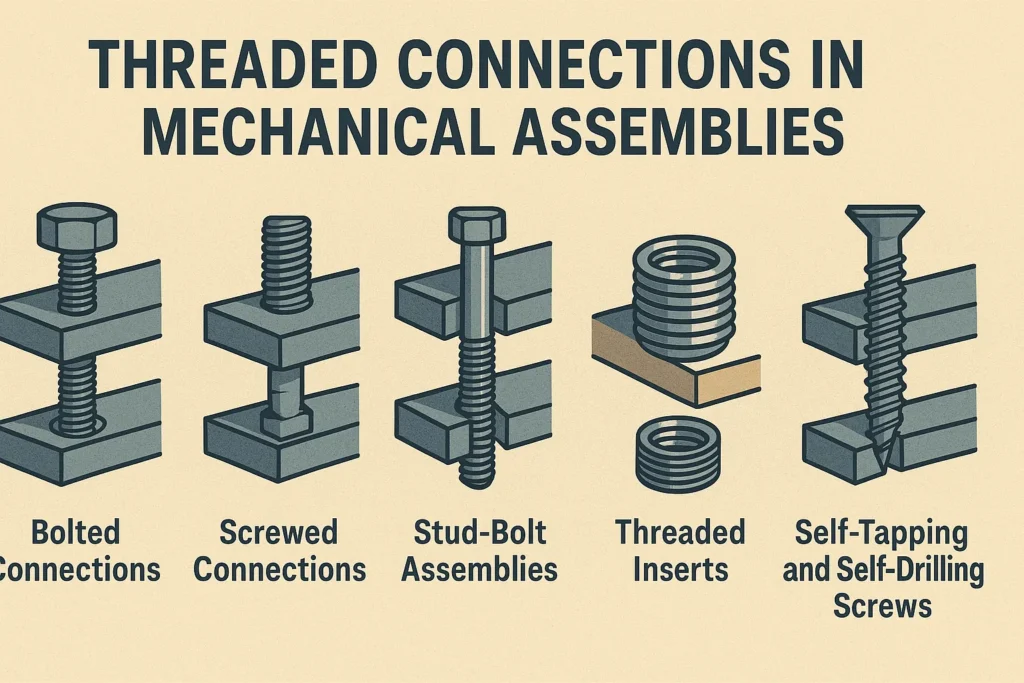

Types of Threaded Connections

There are various types of threaded connections; it depends on the requirements and environment.

1. Bolted Joints

A bolt passes through holes in two parts and is secured with a nut. This allows for strong, reusable joints. It’s used in most mechanical assemblies structures.

2. Tapped Holes

Threads are cut directly into one of the components, and they are used when one side of the machinery cannot accommodate a nut, such as engine blocks or housings.

3. Pipe Threads

These threads are slightly tapered to ensure a tight seal when tightened.

4. Self-Tapping Screws

It’s used in softer materials like plastic or thin metal sheets. The screw creates its own thread during installation.

5. Stud Connections

A stud is a threaded rod that remains fixed in one part and allows nuts to be installed or removed on either side.

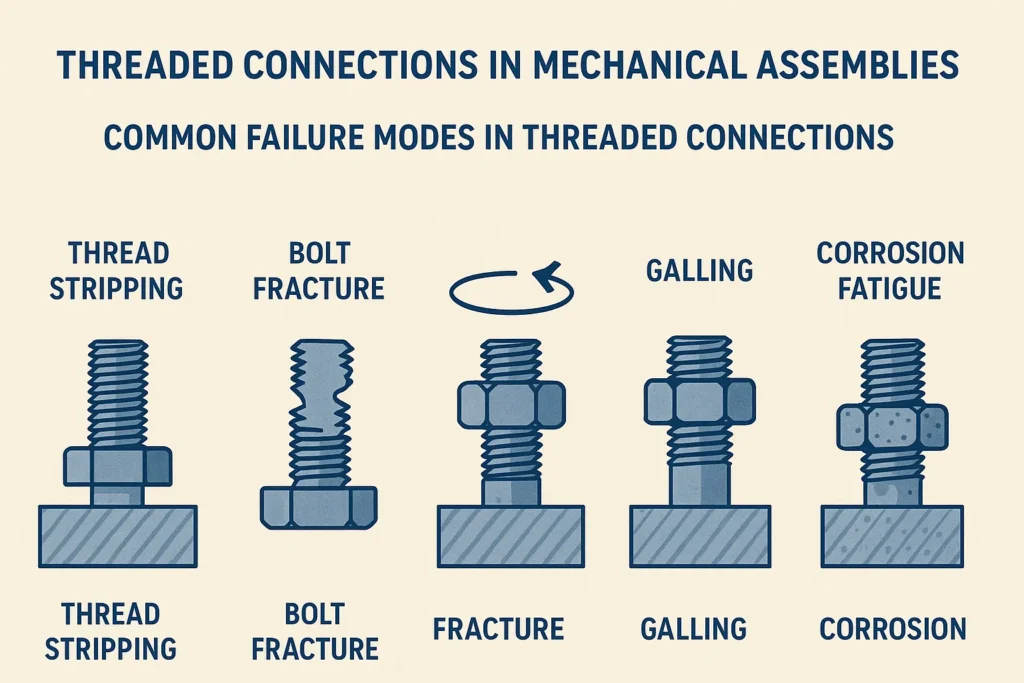

Common Problems in Threaded Assemblies

Even experienced engineers can face some issues if they don’t follow proper steps during assembly.

1. Loose Fasteners

Sometimes bolts can become loose because of vibration, temperature change, or not tightening the bolts properly. The best solution for this is to use a lock washer or self-locking nuts to prevent these problems.

2. Thread Stripping

Thread stripping happens when too much torque is applied, and it exceeds the strength of the material. The solution to this problem is, follow the correct torque values and use the right tools to keep things balanced.

3. Corrosion

Threads may be damaged by the use of moisture or chemical exposure. To prevent this, use a corrosion-resistant coating or material like stainless steel.

4. Fatigue Failure

By the time the fasteners are weakened because of repeated loading and unloading. The best solution is to use fatigue-resistant materials and maintain proper preload.

Modern Tools

Modern tools have made things easier for designers to design and monitor the connections accurately. These tools use sensors and use digital torque measurement tool to measure the tension. Softwares like CAD and simulation tools allow engineers to visualise stress distribution and predict failure before production starts.

Real-World Applications

In the real world, you may see threaded connections everywhere

- It’s used in the automotive industry, and threaded connections are applied to engines and suspensions.

- In the aerospace industry, it’s used in aircraft structures.

- In the power sector, threaded connections are used in oil, gas, and turbines, depending on the joints that can handle that much stress.

All these industries follow strict standards to make sure that every connection performs safely under demanding conditions

Safety and Quality Standards

All industries have to follow the strict guidelines of ISO, ASME, and DIN for thread design and torque values. Following these standards ensures compatibility, reliability, and safety. In industries, the QA engineer also performs quality checks, like:

- Visual inspection of threads

- Testing Torque

- Tensile and fatigue tests

- Coating and corrosion checks

These tests confirm that the fasteners meet specifications before use.

Improving Performance Through Innovation

Mechanical assemblies help in CAD Models to create any design according to the client’s requirements. Here are some new materials and technologies that continue to improve threaded connection reliability. We deliver many services in CAD solutions, but we also care about what our potential customers think. So to take care of it, we do every work properly. We believe in building relations because having a good relationship with your clients builds their interest. Mechanical assemblies help clients to understand dimensions, BOM, etc.

Some advancements include:

- Anti-corrosion and anti-galling coatings extend service life.

- Aluminium and titanium fasteners reduce overall weight without sacrificing strength.

- It’s equipped with sensors to monitor preload and detect loosening.

- It allows custom thread geometries for specific applications.

These technologies make mechanical assemblies safer, more efficient, and easier to maintain.

Key Takeaways

- Threaded connections are vital for strength, safety, and maintenance flexibility in mechanical assemblies.

- They use proper design, material selection, and torque application to prevent costly failures.

- In industries, they do inspections on a daily basis and adhere to standards to ensure long-term reliability.

- Modern tools to enhance performance and reduce human errors.

Conclusion

These connections may look so simple, but they’re the foundation of every machine. With mechanical assemblies, you can create any design accurately. Engineers understand how to design and assemble it properly. Mechanical assemblies are the mid-step in CAD. So if you want to enhance your business accuracy, you should consider mechanical assemblies. Now, if you’re designing engines, pipelines, or manufacturing equipment, mastering threaded connections means building systems that last longer, perform better, and cost less to maintain. In mechanical assemblies engineering, success comes from the smallest details, and threads are one of them.

I have learn several just right stuff here. Definitely worth bookmarking for revisiting. I surprise how much attempt you put to create such a magnificent informative site.

hello,

Our consultant firm based in the USA and our client are interested in your products.

Could you provide your company brochure and respond from your official email id (if different from the current in use), so i can send you the client’s requirement.

Payment before production.

I await your answer.

Regards,

MrSmith

Hello Mr. Smith,

Thank you for reaching out. We’ve sent a detailed response along with our company brochure to your email, Please take a look.