Introduction

Aerospace design makes aviation design better. In this modern world of engineering, engineers don’t compromise on precision and safety. All components of the aircraft system must follow the international safety standards. The standard that is used globally for the aircraft industry is AS 9100. This standard ensures that all these companies, which include development and manufacturing processes, must follow the strict guidelines for safety and precision.

This guide helps you understand the guidelines of AS 9100. Its importance and how industries can implement to achieve precision.

What Is AS 9100?

In the aerospace industry, every manufacturer and supplier must comply with strict quality standards to ensure safety and reliability. Each organization is expected to provide complete documentation of its design and production processes. AS 9100 serves as the benchmark, outlining the essential requirements that all aerospace companies must follow.

Created by the International Aerospace Quality Group (IAQG), AS 9100 is an internationally recognized quality management standard tailored specifically for the aerospace design sector. It builds upon the foundation of ISO 9001, adding extra criteria focused on product safety, risk management, and performance consistency, making it the leading standard for aerospace quality assurance.

Why AS 9100 Matters in Mechanical and Aerospace Design

These organizations need extreme precision for the safety of the product. A single design error can result in costly failures and safety risks. These international standards ensure the whole structured process and improved quality and communication.

Here are a few major points why the AS 9100 standards are important for mechanical and aerospace design engineering.

- Enhances Design Quality

It ensures every design meets the given standards for safety and performance, and it includes regular reviews and testing to confirm that the design works correctly. - Reduces Errors and Rework

Engineers can avoid errors by following these standards strictly, and in this way, manufacturers can save time and money. - Improves Supplier Reliability

These companies follow strict guidelines and ensure that materials are always of high quality. - Supports Continuous Improvement

The team of engineers regularly reviews performance data and identifies opportunities for better design results. - Builds Global Trust

AS 9100 certification shows clients and partners that your organization meets world-class aerospace design quality standards.

Key AS 9100 Requirements for Design Teams

While AS 9100 covers all aspects of manufacturing and operations, several clauses are particularly important for mechanical and aerospace design teams. These requirements help ensure the design process is safe.

1. Design Planning and Requirements

Every project begins with understanding what the client needs. AS 9100 requires a clear plan before any work starts.

Here are a few strategies that we follow:

- What the design must achieve.

- Who is responsible for each part?

- How will we check quality and progress?

A clear path keeps everyone on the same page, and it ensures consistent results.

2. Managing Risks

A small design mistake can cause big safety issues. AS 9100 focuses on risk-based thinking, which means identifying problems early and preventing them. At DesignHok, our team carefully studies each design to find possible weak points. We then create solutions before moving forward. This saves time, reduces cost, and improves overall safety.

3. Configuration Management

When designing aircraft, even small changes can have big effects. AS 9100 requires companies to track and control every design change. We use these tools to manage and document every update, and this ensures everyone is working on the right version of a design to avoid confusion.

4. Reliable

We use modern software to check how each part behaves in different flight conditions. This helps us to create safe and dependable aircraft systems for our clients. We perform analysis by using modern simulation tools such as stress testing to ensure that the design is accurate and solves real-world problems.

5. Design Change Control

Design changes are normal in engineering, but in aerospace design, they must be handled carefully.

In our firm, every design goes through more than one quality check to confirm everything. We ensure that each model meets the international standards and performance.

6. Verification and Validation

Verification and validation are two important parts of AS 9100.

- Verification checks if the design meets specifications.

- Validation confirms that the design performs as expected in real life.

We use both these tests through 3D simulations and a prototype. If a model passes all tests, then it’s sent for ready to production. This ensures that our work is precise and accurate.

How AS 9100 Impacts Mechanical Design

It makes sure every component meets exact specifications before production starts.

They must focus on:

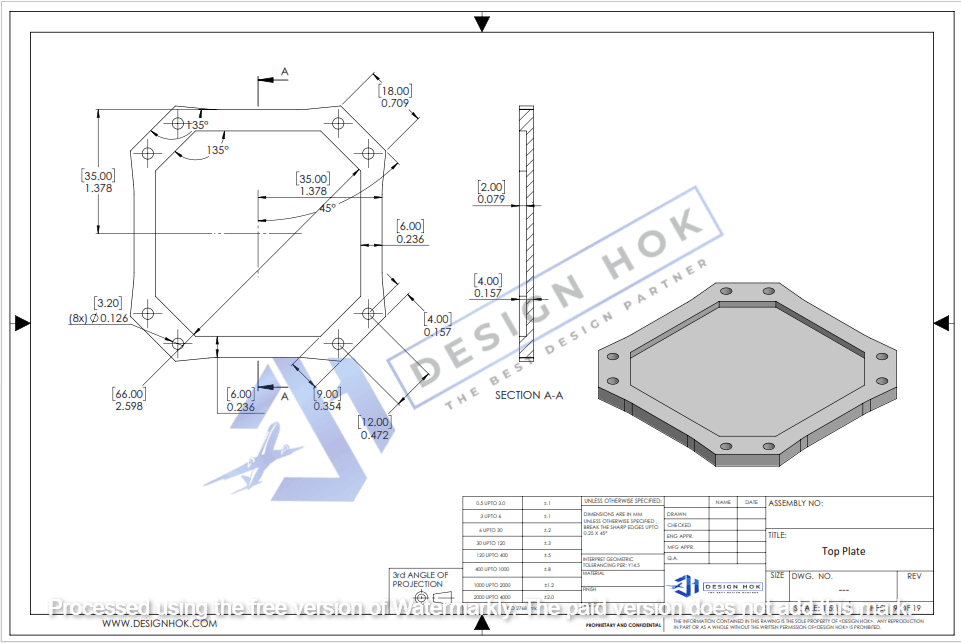

- Precision drafting and modeling using advanced tools.

- They inspect the tool by stress analysis.

- They test the material to ensure performance.

This workflow helps to prevent production errors and ensures smooth integration.

How AS 9100 Impacts Aerospace Design

In this industry, the aircraft component works in an extreme environment, where a small mistake by someone in the team can cause major failures

AS 9100 ensures:

- It ensures full traceability of every design and component.

- The engineers do proper validation through advanced simulations and testing.

- Collaboration between mechanical, electrical, and systems engineers for better integration.

This allows aerospace design teams to meet global aviation safety standards and pass regulatory audits smoothly.

The Benefits of AS 9100 Certification

- Designs are safer, stronger, and more consistent.

- Certification builds confidence among clients and partners.

- It reduces costs through better planning and risk management and minimizes rework.

- They meet global aviation and defense regulations.

- The certified companies stand out in a highly regulated market.

Conclusion

In a world where being precise and safe is key to winning, AS 9100 provides manufacturers with a solid structure to consistently and confidently deliver. Manufacturers earn the trust of aerospace clients, boost their own efficiency, and make sure every product hits the top marks for safety and performance. This is more than just a quality standard, and it ensures precision in mechanical and aerospace design. It gives companies a clear path for managing risks and improving efficiency.