Introduction

In today’s competitive aerospace and defense industries, precision, quality, and safety are non-negotiable. Whether designing aerospace components or managing complex systems, engineering services must align with global quality standards to succeed. One such critical standard is Engineering Services Following AS 9100, a quality management system (QMS) framework specifically tailored for aerospace, aviation, and defense organizations.

This article delves into how Engineering Services Following AS 9100 ensure optimal quality, safety, traceability, and compliance—and why adopting this standard is not just an advantage, but a necessity.

Table of Contents

- What Is AS 9100?

- Why AS 9100 Matters for Engineering Services

- Core Elements of AS 9100 in Engineering

- Types of Engineering Services That Require AS 9100 Compliance

- Benefits of Engineering Services with AS 9100 Certification

- Steps to Align Engineering Services with AS 9100

- Key Industries That Demand AS 9100-Compliant Engineering

- AS 9100 vs. ISO 9001: What Makes AS 9100 Unique?

- Common Pitfalls in Engineering Compliance and How to Avoid Them

- Future of AS 9100 in Digital Engineering

- Final Thoughts

- FAQ Section

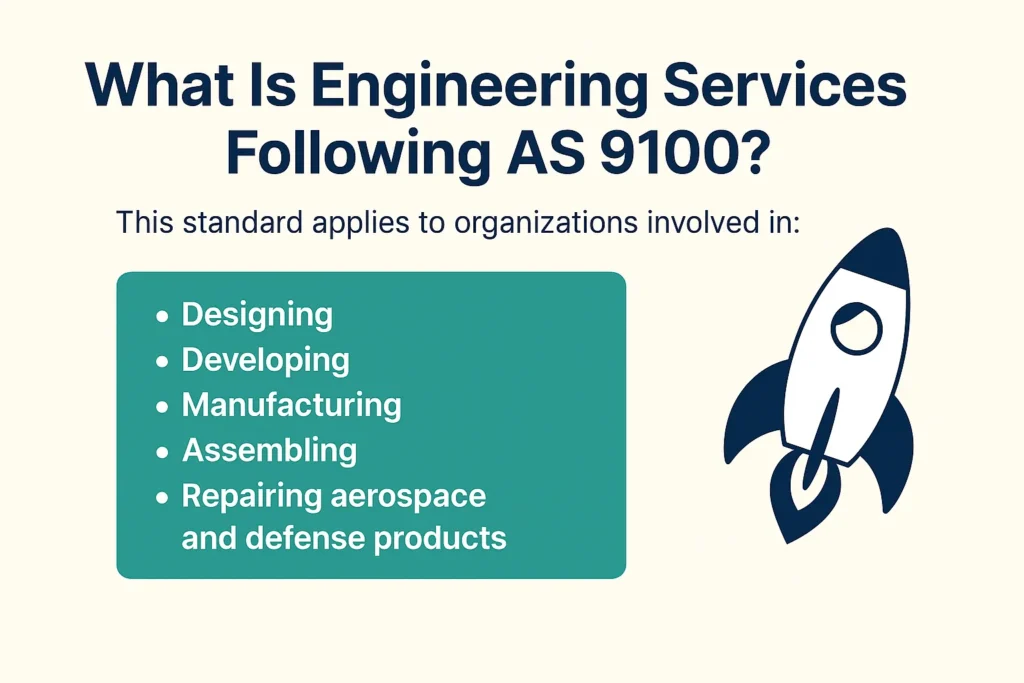

1. What are Engineering Services Following AS 9100?

Engineering Services Following AS 9100 is an international standard developed by the International Aerospace Quality Group (IAQG). It builds upon ISO 9001, adding extra requirements that are specific to the aviation, space, and defense sectors. These additional clauses cover risk management, product safety, traceability, and more.

This standard applies to organizations involved in Engineering Services, following AS 9100:

Designing:

Creating detailed plans and specifications to develop functional, efficient aerospace and defense systems or components.

Designing Aerospace Systems:

Creating detailed blueprints and models to ensure aerospace components meet performance, safety, and regulatory requirements before production.

Developing:

Transforming design concepts into workable prototypes through testing, refinement, and engineering optimization processes.

Developing Prototypes and Systems:

Transforming design concepts into functional prototypes through simulation, testing, and iteration to validate aerospace system performance and reliability.

Assembling:

Combining manufactured parts into complete systems, ensuring proper fit, alignment, and functional integration.

Assembling Complex Systems:

Integrating mechanical, electronic, and structural parts to build complete aerospace or defense systems that meet exact performance specifications.

Repairing Aerospace and Defense Products:

Restoring damaged or worn aerospace components to operational condition through inspection, replacement, or rework procedures.

When engineering services align with AS 9100, they demonstrate a commitment to consistent quality, customer satisfaction, and regulatory compliance.

2. Why AS 9100 Matters for Engineering Services

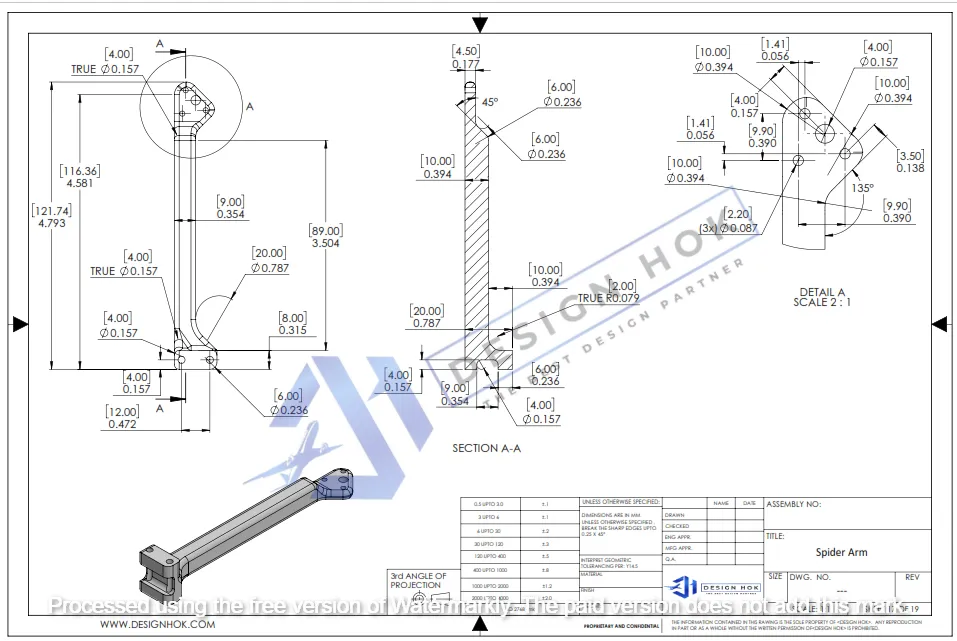

Engineering services are foundational to every phase of aerospace product development. From early CAD modeling and FEA simulations to prototyping and systems integration, engineers must follow a strict quality structure.

Engineering Services Following AS 9100 ensures that engineering teams:

- Understand and manage customer-specific requirements

- Prevent failures through risk-based thinking

- Apply configuration management for design changes

- Maintain documentation for traceability and audits

By complying with AS 9100, engineering firms can assure clients and authorities of their reliability, accuracy, and accountability.

3. Core Elements of Engineering Services Following AS 9100

Here’s how AS 9100 maps onto engineering workflows:

a. Customer Focus and Requirements

Engineering firms must understand technical and contractual needs and ensure deliverables align precisely with customer expectations.

b. Risk and Opportunity Management

Risk management is embedded in the design and testing phases, with tools such as:

- FMEA (Failure Mode and Effects Analysis)

- Design risk reviews

- Safety case evaluations

c. Product Safety and Control

Engineering Services, following AS 9100, are responsible for identifying critical design features that could affect safety and ensuring proper verification methods are in place.

d. Configuration Management

Design versioning and documentation are controlled so that all stakeholders work from the same configuration baseline.

e. Validation and Verification

Whether it’s a structural simulation or a thermal analysis, validation ensures the system meets intended performance, and verification ensures specifications were followed.

4. Types of Engineering Services That Require AS 9100 Compliance

The following services typically require strict adherence to AS 9100 standards:

- Mechanical and Aerospace Design

- Airframe and propulsion systems

- CAD/CAM modeling

- Electrical Engineering

- Avionics systems

- Sensor and telemetry integration

- Software Engineering

- Embedded software for flight controls

- Firmware for navigation systems

- Systems Engineering

- Integrated system design and trade studies

- Testing and Simulation

- Thermal, vibration, fatigue, and FEA tests

- Prototyping and Rapid Development

- Additive manufacturing of components

5. Benefits of Engineering Services with AS 9100 Certification

a. Higher Client Trust

AS 9100-certified engineering firms are often pre-approved vendors for top OEMs like Boeing, Lockheed Martin, and Airbus.

b. Reduced Project Risk

Quality and safety issues are identified and mitigated early in the design lifecycle.

c. Streamlined Workflow

A process-based approach aligns engineering operations with customer expectations, compliance requirements, and best practices.

d. Improved Collaboration

Engineering teams have clearly defined roles, tools, and documentation methods for effective cross-functional collaboration.

e. Access to Global Markets

AS 9100 is recognized worldwide, enabling entry into international defense and aerospace supply chains.

6. Steps to Align Engineering Services with AS 9100

Step 1: Conduct a Gap Analysis

Evaluate your current QMS against Engineering Services, following AS 9100 to identify missing elements.

Step 2: Establish a Process-Based QMS

Define engineering processes—requirements gathering, prototyping, testing—and map them to AS 9100 clauses.

Step 3: Train Teams

Educate engineers, project managers, and QA personnel on AS 9100 compliance requirements.

Step 4: Integrate Risk Management Tools

Embed FMEA, HAZOP, and other tools into the design and development phases.

Step 5: Document Everything

Maintain records of design versions, validations, changes, risk reviews, and testing.

Step 6: Internal Audits and Pre-Assessments

Audit your engineering workflows regularly to prepare for third-party certification audits.

7. Key Industries That Demand Engineering Services Following AS 9100

Aerospace Manufacturing

Designing and testing components like fuselage sections, control surfaces, and wing structures.

Satellite Systems

Engineering satellite platforms, payload systems, and ground control interfaces.

Defense Equipment

Design of armored vehicles, missile systems, communication systems, and battlefield electronics.

Commercial Aviation

Engineering for passenger aircraft interiors, seating systems, cockpit interfaces, and safety mechanisms.

8. AS 9100 vs. ISO 9001: What Makes AS 9100 Unique?

| Feature | ISO 9001 | AS 9100 |

|---|---|---|

| Target Industry | All sectors | Aerospace, Aviation, Defense |

| Risk Management | General requirement | Detailed, sector-specific |

| Product Safety | Not emphasized | Mandatory |

| Counterfeit Parts Control | Optional | Required |

| Configuration Management | Not mandatory | Mandatory |

| Supplier Controls | Moderate | Rigorous with traceability |

AS 9100 is tailored to address the high risk and complexity associated with aerospace systems.

9. Common Pitfalls in Engineering Services Following AS 9100 Compliance and How to Avoid Them

- Poor Documentation: Fix by adopting a digital document control system.

- Incomplete Risk Analysis: Integrate risk reviews into every design milestone.

- Lack of Training: Set up continuous training and awareness sessions.

- Weak Supplier Oversight: Regularly audit and evaluate supplier quality systems.

- Inconsistent Design Reviews: Create structured, multi-phase design review gates.

10. Future of Engineering Services Following AS 9100 in Digital Engineering

As the industry shifts toward model-based systems engineering (MBSE) and digital twins, AS 9100 compliance must evolve. Future versions may include:

- Digital thread traceability

- Cybersecurity clauses

- AI-based defect prediction

Firms that digitize their QMS and adopt AI-powered quality analytics will stay ahead in the next wave of engineering excellence.

11. Final Thoughts

Engineering services that follow Engineering Services Following AS 9100 don’t just deliver quality—they build confidence, reduce risks, and unlock global opportunities. With growing complexity in aerospace products, compliance with AS 9100 is becoming a strategic advantage rather than a regulatory checkbox.

Whether you’re a design consultancy, systems integrator, or testing lab, aligning your processes with AS 9100 will prepare you to meet client demands, pass audits, and compete on a global stage.

12. Frequently Asked Questions (FAQ)

Q1. Why is AS 9100 important for engineering services?

Engineering Services Following AS 9100 ensures that engineering processes meet aerospace-level quality and safety requirements, minimizing risk and improving customer satisfaction.

Q2. How do engineering firms get AS 9100 certified?

They must implement a compliant QMS, conduct internal audits, correct non-conformities, and pass a third-party audit by an accredited registrar.

Q3. What engineering services benefit most from AS 9100?

Mechanical design, avionics engineering, systems integration, embedded software development, and aerospace testing services gain the most from AS 9100.

Q4. How is AS 9100 different from ISO 9001?

While ISO 9001 is general, AS 9100 includes aerospace-specific clauses for risk management, product safety, configuration control, and counterfeit prevention.

Q5. What are the challenges of AS 9100 implementation?

Challenges include staff resistance, documentation overload, audit preparation, and the need for robust supplier evaluation systems.