Description

AS 9100 Drafting Services by DesignHOK tailored for aerospace, defense, and aviation manufacturing. Discover how our precise 2D drafting solutions ensure regulatory excellence, support manufacturing accuracy, and help clients achieve traceable, standardized documentation that meets the world’s most demanding aerospace standards.

Table of Contents

- Introduction to AS 9100 Drafting

- Why AS 9100 Matters in Aerospace Drafting

- Role of Technical Drafting in AS 9100 Compliance

- How DesignHOK Delivers AS 9100 Drafting Services

- Key Features of Our Aerospace Drafting Deliverables

- Tools and Technologies Used at DesignHOK

- Benefits of Choosing DesignHOK for AS 9100 Drafting

- Drafting Support for Aerospace QMS

- Common Industries Served

- Our Process: From Inquiry to Delivery

- Final Thoughts

- Frequently Asked Questions (FAQ)

1. Introduction to AS 9100 Drafting Services by DesignHOK

AS 9100 Drafting Services by DesignHOK refer to technical documentation and drawing creation aligned with the stringent aerospace quality standards defined by the AS 9100 series. These drawings form the backbone of engineering communication across the aerospace supply chain, ensuring every part, assembly, and system complies with ISO-based aerospace standards.

At AS 9100 Drafting Services by DesignHOK team understands the importance of accuracy, clarity, compliance, and traceability, which are central to aerospace documentation workflows.

2. Why AS 9100 Drafting Services by DesignHOK Matters in Aerospace

The AS 9100 Drafting Services by DesignHOK is designed to enhance product safety, airworthiness, and risk management within the aerospace industry. In drafting terms, this means:

- Ensuring revision control

- Enabling traceable documentation

- Following configuration management

- Using standardized symbols and dimensioning

Without compliant drafting, even the best designs can result in manufacturing errors, regulatory violations, or safety risks.

3. Role of Technical AS 9100 Drafting Services by DesignHOK

Drafting plays a mission-critical role in the AS 9100 certification journey. According to the standard, organizations must:

- Define technical requirements clearly

- Maintain controlled records for every drawing

- Update changes with full revision history

- Ensure drawings match actual manufacturing output

At DesignHOK, we structure our drafting output to directly support a client’s QMS (Quality Management System) documentation and audit readiness.

4. How DesignHOK Delivers AS 9100 Drafting Services

DesignHOK offers end-to-end drafting services fully integrated with the expectations of AS 9100 certification. Our workflows focus on:

- Precise 2D drafting for aerospace components, assemblies, and tooling

- Full documentation sets including BOMs, GD&T annotations, and notes

- AS 9100-aligned file naming conventions and control protocols

- Support for revision tracking, approval stages, and auditable formats

Each project undergoes strict internal quality reviews, ensuring it’s compliant, accurate, and ready for client audits.

5. Key Features of Our Aerospace Drafting Deliverables

DesignHOK’s AS 9100 drafting solutions include:

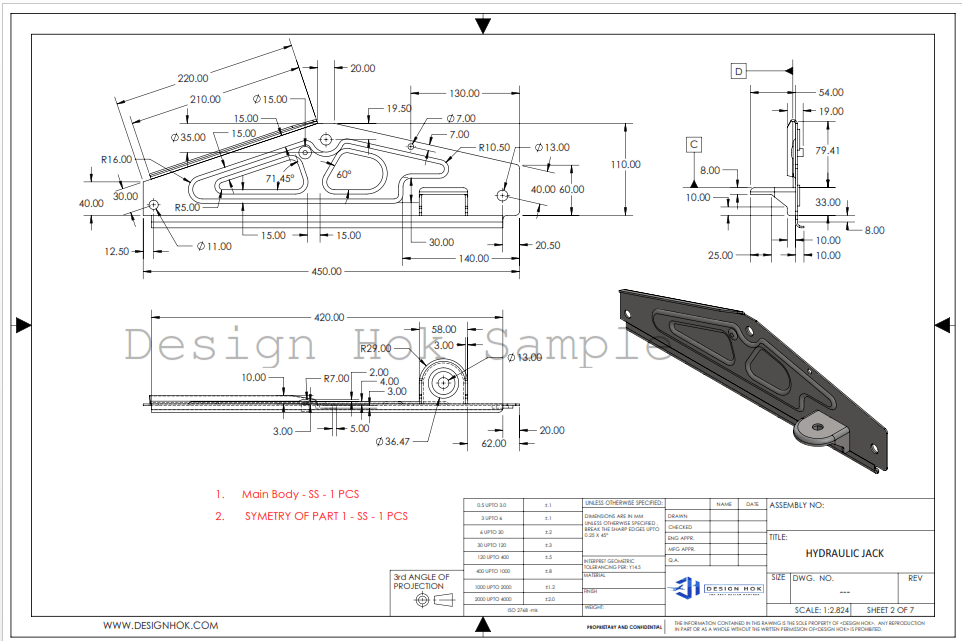

2D Engineering Drawings:

Precise technical illustrations showing component dimensions, shapes, and specifications.

What Are 2D Engineering Drawings?

2D engineering drawings are flat representations of components, showing dimensions, geometry, and technical details used for manufacturing and inspection.

Why They Matter?

They provide accurate visual communication between designers and manufacturers, ensuring every part is built to exact specifications with minimal error.

Exploded Views & Assembly Drawings:

With full configuration control

Tolerance Analysis & GD&T Annotations:

For precision manufacturing

Revision Blocks & Title Blocks:

Designed per AS 9100 and ISO standards

Standardized Layers, Linetypes, and Fonts:

For universal interoperability

We ensure all deliverables are compatible with downstream CAM, CNC, and PLM systems.

6. Tools and Technologies Used at DesignHOK

To meet the highest industry standards, DesignHOK uses:

- AutoCAD Mechanical

- SolidWorks Drafting Module

- PTC Creo

- CATIA V5

- Siemens NX

These tools allow us to generate high-accuracy, feature-rich drawings optimized for aerospace manufacturing environments, while supporting multi-format export like DWG, DXF, PDF, and STEP.

7. Benefits of Choosing AS 9100 Drafting Services by DesignHOK

✅ Aerospace-Grade Quality: Drafting that meets the toughest specifications

✅ Full Compliance: Drawings aligned with AS 9100, ISO 9001, and FAA standards

✅ Scalability: From prototyping to production runs

✅ Global Reach: Supporting suppliers, OEMs, and Tier 1 manufacturers

✅ Audit-Ready Output: Built-in traceability, documentation, and version control

✅ Fast Turnaround: Optimized delivery workflows with client collaboration

We also support corrective action documentation and drawing-related NCR resolutions, aligning with continual improvement practices under AS 9100.

8. Drafting Support for Aerospace QMS

AS 9100 requires documented information to be:

- Accurate

- Identifiable

- Traceable

- Protected

AS 9100 Drafting Services by DesignHOK deliverables are structured to fit directly into your QMS architecture, with metadata fields, version tracking, and approval workflows. We also help clients:

- Create drawing master lists

- Align document control processes

- Track drawing changes for product lifecycle management (PLM)

9. Common Industries Served

DesignHOK delivers AS 9100 drafting services for:

- Commercial Aviation

- Defense Contractors

- UAV / Drone Manufacturers

- Satellite and Spacecraft Builders

- Aircraft Tooling Suppliers

- MRO (Maintenance, Repair, and Overhaul) organizations

We also serve Tier 1 and Tier 2 suppliers who must align with OEM compliance mandates.

10. Our Process: From Inquiry to Delivery

Our AS 9100-compliant workflow follows these steps:

- Project Scoping: Define drawing needs, standards, and timelines

- Data Collection: Intake of sketches, 3D files, specs, or legacy blueprints

- Drafting and Documentation: Engineering team generates 2D drawings

- Review and Validation: QA checks for AS 9100 compliance

- Client Approval: Review drafts and provide feedback

- Final Delivery: Certified, formatted, and audit-ready file sets

We also provide ongoing revision and change support, so your documents evolve with your projects.

11. Final Thoughts

In the aerospace industry, precision and compliance are not optional—they are mission-critical. With AS 9100 Drafting Services by DesignHOK, manufacturers gain a trusted documentation partner that understands the language of quality and the discipline of design.

Our AS 9100 Drafting Services by DesignHOK help ensure that your components are manufactured correctly, audited confidently, and delivered to specification. Whether you’re preparing for certification, scaling operations, or managing a complex supply chain, DesignHOK is your go-to drafting provider for regulatory-ready success.

12. Frequently Asked Questions (FAQ)

Q1: What is AS 9100 drafting?

AS 9100 drafting involves creating technical engineering drawings that comply with aerospace standards defined in AS 9100. It ensures accuracy, traceability, and standardized documentation for aerospace and defense manufacturing.

Q2: Why do aerospace companies need AS 9100-compliant drawings?

AS 9100 requires accurate, controlled documentation as part of the quality management system. Compliant drawings reduce errors, enhance safety, and streamline audits.

Q3: How does DesignHOK ensure AS 9100 compliance in drafting?

We follow strict internal standards including revision control, GD&T practices, layer management, and traceable file handling. Every drawing undergoes peer reviews and quality checks before delivery.

Q4: What file formats do you provide?

We deliver drawings in industry-standard formats including DWG, DXF, PDF, and on request, STEP or IGES files compatible with PLM and manufacturing systems.

Q5: Do you offer support for drawing revisions and updates?

Yes. DesignHOK provides revision support, helping clients maintain drawing version history and incorporate engineering changes per AS 9100 documentation protocols.