In this world, where quality and safety are everything. Every aircraft part, from the wings to the engine component all parts has to work perfectly and meet strict safety rules. Even a minor mistake can cause big problems. We don’t just follow international standards. We use these standards to improve the design and ensure project excellence. In this guide, we’ll learn about what AS 9100 Design Standards are and their importance in the engineering field, and how DesignHok applies them to deliver safe and advanced aircraft designs.

What Is AS 9100?

AS 9100 Design Standards is an international quality management standard, developed by the International Aerospace Quality Group (IAQG). It is specially designed for the aerospace industry. It is based on ISO 9001. ISO 9100 is a general quality standard, but it includes some extra requirements(related to safety and reliability), which is why it is called AS 9100 Design Standards. To manufacture or supply any parts in this industry, they must have to follow these standards. The organisation must show its design and documentation. AS 9100 Design Standards sets a strict guideline for aerospace companies. In short, when a firm is AS 9100 Design Standards certified, it means you can trust their process, quality, and commitment to excellence.

How AS 9100 Shapes the Aerospace Design Process

It is a mix of creativity, engineering, and responsibility. It’s not just about creating something new; it’s about creating something that works safely. AS 9100 Design Standards gives us a structured system to manage every part of this process, from early planning to final testing.

1. Design Planning and Requirements

Every project begins with understanding what the client needs. AS 9100 requires a clear plan before any work starts.

Here are a few strategies that we follow:

- What the design must achieve.

- Who is responsible for each part?

- How will we check quality and progress?

This flow of work ensures that every design stage is organised.

2. Managing Risks

It involves high risks, and small design mistakes can cause big safety issues. AS 9100 focuses on risk-based thinking, which means identifying problems early and preventing them. At DesignHok, our team carefully studies each design to find possible weak points. We then create solutions before moving forward. This saves time, reduces cost, and improves overall safety.

3. Configuration Management

When designing aircraft, even small changes can have big effects. AS 9100 Design Standards requires companies to track and control every design change. We use these tools to manage and document every update. This makes sure everyone is working on the right version of a design to avoid confusion. If something changes, like material, then the engineer reviews it properly.

4. Safety and Reliability

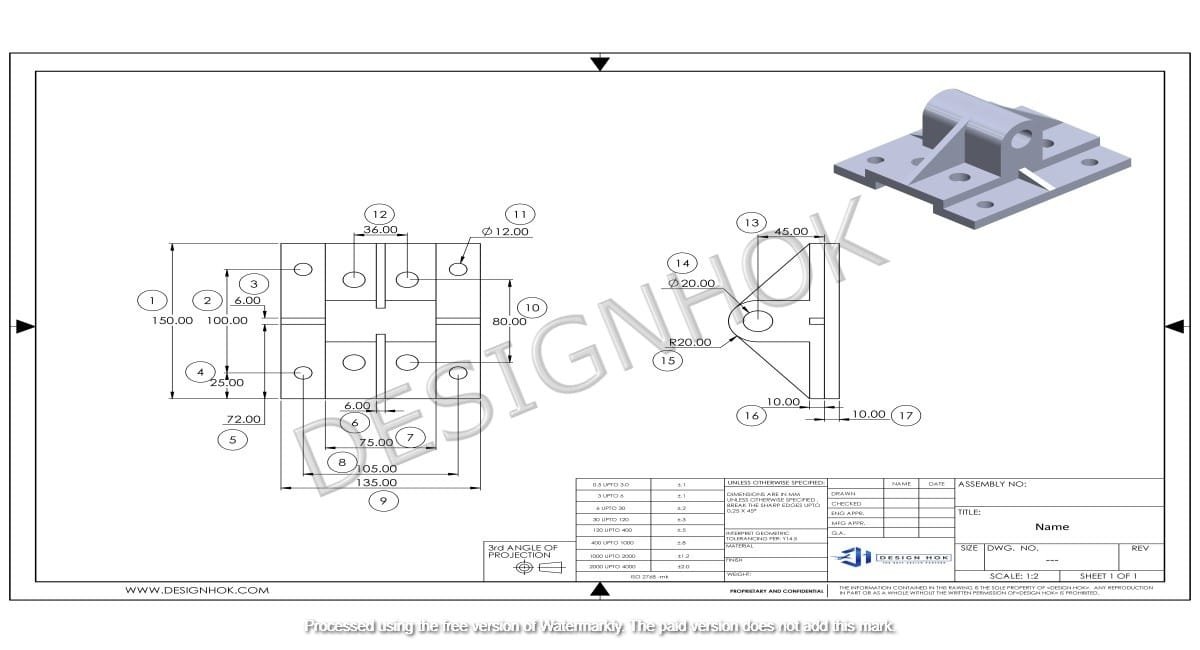

We use advanced software to check how each part behaves in different flight conditions. This helps us to create safe and dependable aircraft systems for our clients. We perform analysis by using modern simulation tools such as stress testing and thermal analysis to ensure that the design is accurate and solves real-world problems.

5. Design Change Control

Design changes are normal in engineering, but in aerospace, they must be handled carefully. In our firm, every design goes through more than one quality check to confirm everything. We ensure that each model meets the international standards and performance.

6. Verification and Validation

Verification and validation are two important parts of AS 9100.

- Verification checks if the design meets specifications.

- Validation confirms that the design performs as expected in real life.

We use both these tests through 3D simulations and a prototype. If a model passes all tests, then it’s sent for ready to production. This ensures that our work is precise and accurate.

Benefits of Following AS 9100

Following AS 9100 offers real benefits both for our company and our clients.

1. Consistent Quality

All projects must follow the same given process. This ensures accuracy, repeatability, and high quality in every design we create.

2. Full Traceability

We keep a clear record of each design step. Clients can see how decisions were made, what changes were applied, which builds transparency and trust.

3. Reduced Risks

We focus on risk assessment and quality checks at every stage, and we minimise costly mistakes and improve project reliability.

How DesignHok Uses AS 9100 Every Day

A quality isn’t a one-time goal; it’s part of everything we do.

Here’s how we apply these standards in daily operations:

- Our team members are trained on AS 9100 principles, so they understand how to maintain quality at every level.

- Our team create proper documentation of all design and review steps to ensure consistency.

- We work only with reliable suppliers who also follow strict aerospace standards.

- All design decision is inspected by testing and simulation data.

- The regular inspection to check performance and correct errors ensures ongoing compliance.

The Future of Aerospace Design and AS 9100

For DesignHok, AS 9100 is more than just a checklist of regulations. Building a solid base for future space tech advancements, we’re aiming to create systems that are lighter, safer, and more intelligent, all while keeping up the same high-quality and maintaining credibility.

Final thoughts

AS 9100 isn’t just a certification; it’s a commitment to doing things accurately. For Design Hok, it’s the key to achieving aerospace design excellence, guiding us and how we can plan, create, and improve every design. By following AS 9100 standards, we ensure that every aircraft design meets expectations globally.