Description:

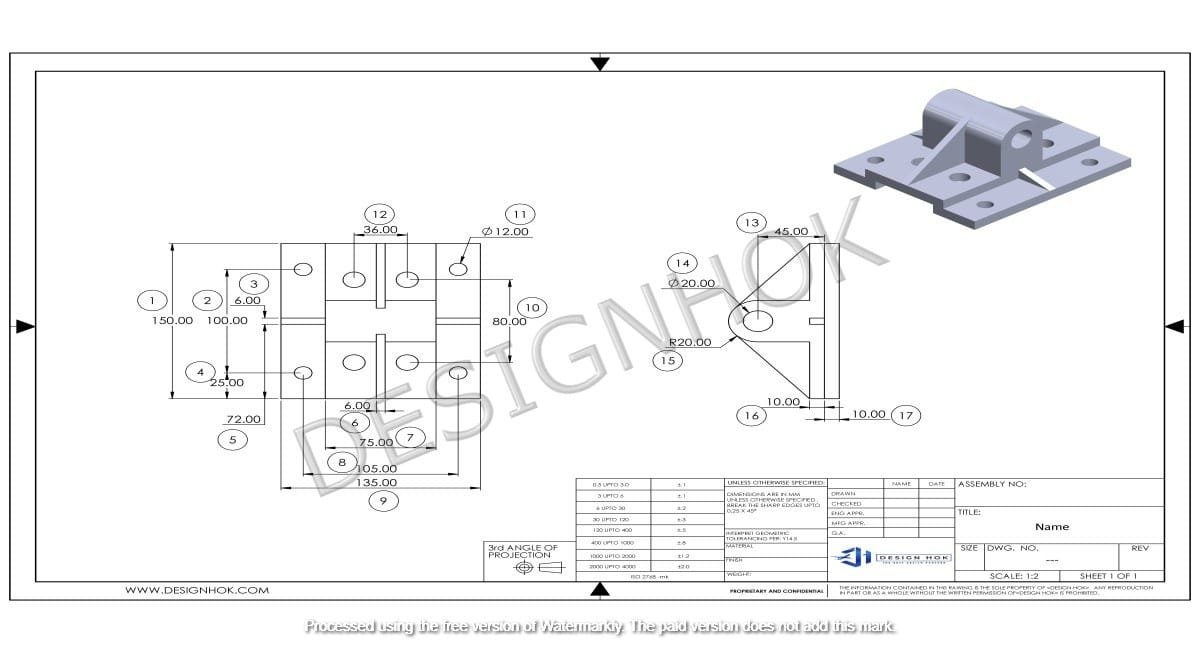

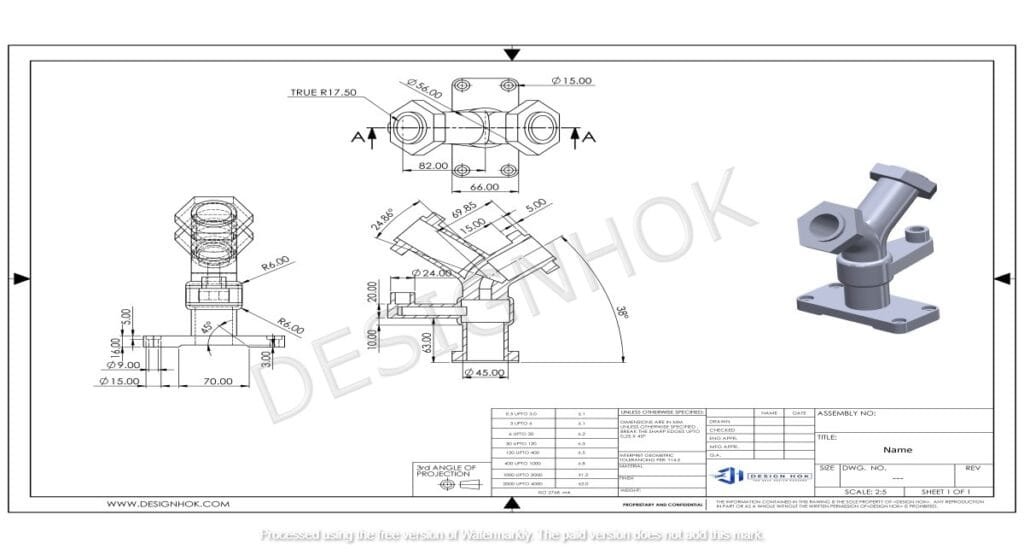

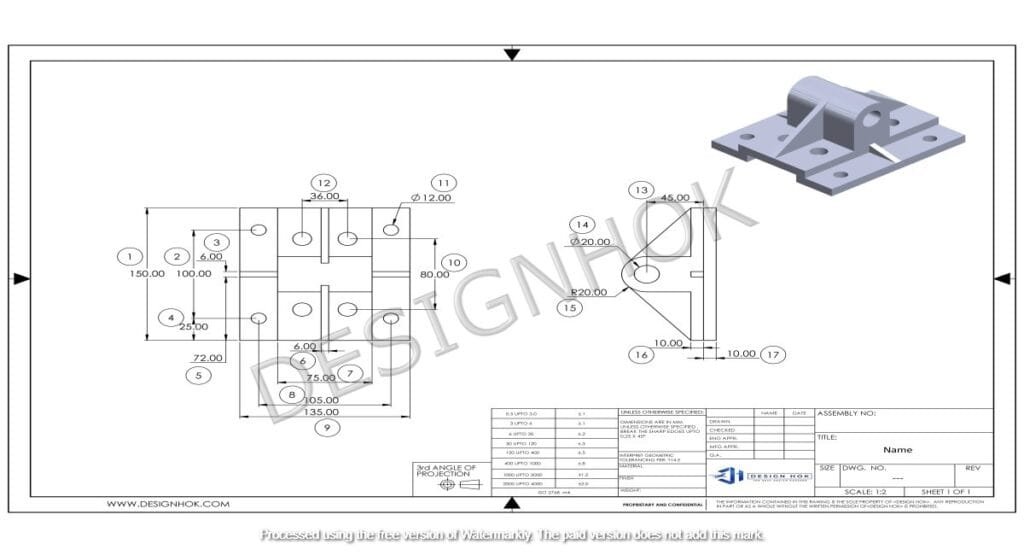

Discover the key Machine Elements in Mechanical Design that form the backbone of mechanical design for Design Hok. This explores components like shafts, gears, fasteners, and bearings, explaining their significance in creating efficient and reliable mechanical systems. These elements contribute to innovative and durable designs.

Machine Elements in Mechanical Design for Design Hok

Machine Elements in Mechanical Design is a fascinating field that combines creativity and precision to develop machines and systems that solve real-world problems. At the heart of Machine Elements in Mechanical Design are machine elements—key components that work together to create functional and efficient systems. For Design Hok, understanding these elements is vital to producing high-quality designs that meet industry standards. This blog explores the essential machine elements used in mechanical design and their roles in ensuring success.

1. Shafts

Shafts are one of the most fundamental machine elements. They transmit power from one part of a machine to another, typically through rotation. Design Hok utilizes precision-engineered shafts to ensure the smooth and efficient transfer of energy in mechanical systems. Proper alignment and material selection are critical for reducing wear and maintaining durability.

2. Bearings

Bearings are essential for minimizing friction between moving parts. These components support shafts, enabling smooth rotation and reducing energy loss. Bearings come in various types, such as ball bearings, roller bearings, and plain bearings, each suited to specific applications. By integrating high-quality bearings, Design Hok enhances the performance and lifespan of its designs.

3. Gears

Gears are Machine Elements in Mechanical Design marvels that transmit power and motion through meshing teeth. They are used to adjust speed, torque, and direction in machines. Design Hok employs a variety of gears, including spur gears, bevel gears, and worm gears, to create innovative designs that meet diverse requirements. Gears must be carefully designed and aligned to avoid energy loss and wear.

4. Fasteners

Fasteners like bolts, screws, and nuts may seem small, but they play a massive role in mechanical design. They hold components together, ensuring structural integrity and reliability. Design Hok uses advanced fastening techniques to create secure and easily maintainable designs. Selecting the right type of fastener based on the application and load conditions is critical for success.

5. Springs

Springs store and release energy, making them crucial for shock absorption, load distribution, and motion control. Whether it’s compression springs, extension springs, or torsion springs, Design Hok incorporates them to improve the functionality of its mechanical systems. Springs also add flexibility, making machines adaptable to varying loads and conditions.

6. Couplings

Couplings connect two rotating shafts, allowing them to transmit power while accommodating minor misalignments. These elements are vital for reducing vibration and enhancing the longevity of mechanical systems. Design Hok selects couplings based on the system’s requirements, ensuring optimal performance and reliability.

7. Pulleys and Belts

Pulleys and belts are used to transmit power between shafts, often over a distance. This system is efficient, flexible, and cost-effective. Design Hok integrates these elements into its designs for applications that require smooth and reliable power transmission. The correct selection of belt material and pulley dimensions ensures durability and performance.

8. Keys and Keyways

Keys and keyways are simple yet crucial elements used to connect rotating components, such as gears or pulleys, to shafts. They ensure that the component rotates with the shaft without slipping. Design Hok emphasizes precision in machining keyways to maintain system reliability and efficiency.

9. Seals and Gaskets

Seals and gaskets prevent leaks and protect machine components from contaminants like dust and moisture. They are critical in maintaining the efficiency and longevity of mechanical systems. Design Hok uses high-quality seals and gaskets tailored to the operating conditions of each design.

10. Cams and Followers

Cams and followers are used to convert rotary motion into linear motion. These elements are crucial in applications requiring precision and controlled motion. Design Hok incorporates cams and followers in designs that require synchronization and repeatable movements.

The Role of Machine Elements in Design Hok’s Success

At Design Hok, machine elements are more than just components—they are the building blocks of innovation. By understanding the functions and interconnections of these elements, Design Hok creates designs that are efficient, reliable, and tailored to the needs of its clients.

Conclusion

Machine Elements in Mechanical Design are indispensable in mechanical design, providing the foundation for efficient and functional systems. Design Hok’s expertise in integrating these elements ensures that its designs stand out for their quality and performance. Whether it’s a simple fastener or a complex gear assembly, every element contributes to the success of the final product.

FAQs

1. What are machine elements in mechanical design?

Machine elements are the basic components, such as gears, shafts, and bearings, that make up mechanical systems and ensure their functionality.

2. Why are bearings important in mechanical design?

Bearings reduce friction, support moving parts, and enhance the efficiency and durability of mechanical systems.

3. How does Design Hok ensure the quality of its designs?

Design Hok focuses on precision engineering, material selection, and thorough testing to ensure high-quality and reliable designs.

4. What is the role of fasteners in mechanical systems?

Fasteners hold components together, ensuring structural integrity and facilitating maintenance.

5. Can machine elements be customized?

Yes, machine elements can be tailored to meet specific design requirements, ensuring optimal performance and reliability.