DESCRIPTION:

The best mechanical machine design services available, highlighting the critical aspects, unique benefits, and frequently asked questions to help you make an informed decision on choosing the right design service for your project.

Introduction

Mechanical machine design plays a vital role in modern engineering, enabling the creation of efficient, reliable machinery for industries ranging from manufacturing to automotive and beyond. The process of machine design involves a meticulous approach to detail, including mechanical calculations, material selection, 3D modeling, and even simulation testing to ensure products meet performance requirements. Partnering with a high-quality mechanical machine design service provider offers access to technical expertise, precision design capabilities, and innovative solutions tailored to meet specific industry standards.

Key Qualities of the Best Mechanical Machine Design Services

- Technical Expertise and Experience

The best mechanical machine design services bring years of experience in the industry, combining practical knowledge with advanced technical skills. Design engineers work across various fields and applications, enabling them to create solutions for complex machinery that stand up to real-world demands. Providers with a strong portfolio in industries such as aerospace, automotive, and manufacturing can provide insights that lead to highly customized, efficient designs. - Comprehensive Design Solutions

Quality mechanical design services cover every aspect of machine design, from conceptual development to final product validation. These services often include 2D drafting, 3D modeling, and simulation analysis, ensuring all stages of development are accounted for. Comprehensive design capabilities are crucial to producing machines that excel in performance, durability, and functionality. - Focus on Innovation: Innovation is key to maintaining a competitive edge in any industry. Mechanical design services that prioritize research and development provide cutting-edge solutions, whether it’s through new materials, advanced manufacturing techniques, or energy-efficient systems. With an emphasis on staying current with technological advancements, top providers offer forward-thinking designs that stand out in their field.

- Use of Advanced Software and Tools

Modern machine design requires access to powerful software tools that allow engineers to visualize, simulate, and refine their designs. Leading design services use tools like AutoCAD, SolidWorks, and ANSYS for 3D modeling, finite element analysis (FEA), and simulations, helping to predict and mitigate potential flaws before prototyping. This technology-driven approach accelerates the design process and helps ensure the final machine design performs as expected. - Commitment to Industry Standards and Quality Control

Adherence to industry standards and rigorous quality control are essential in mechanical machine design. The best design providers implement ISO, ASTM, and ASME standards in their processes, ensuring every component meets safety and reliability requirements. Quality control measures throughout the design and manufacturing phases add an extra layer of assurance that the machinery will meet regulatory standards and client specifications.

Key Services Offered by Top Mechanical Machine Design Providers

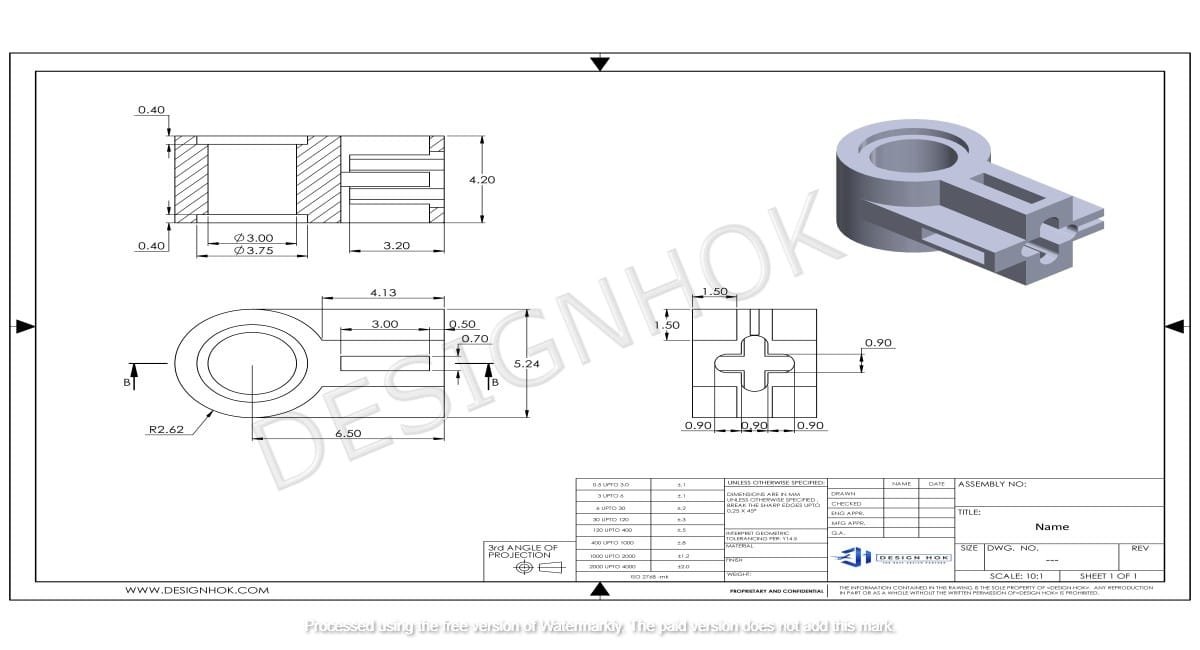

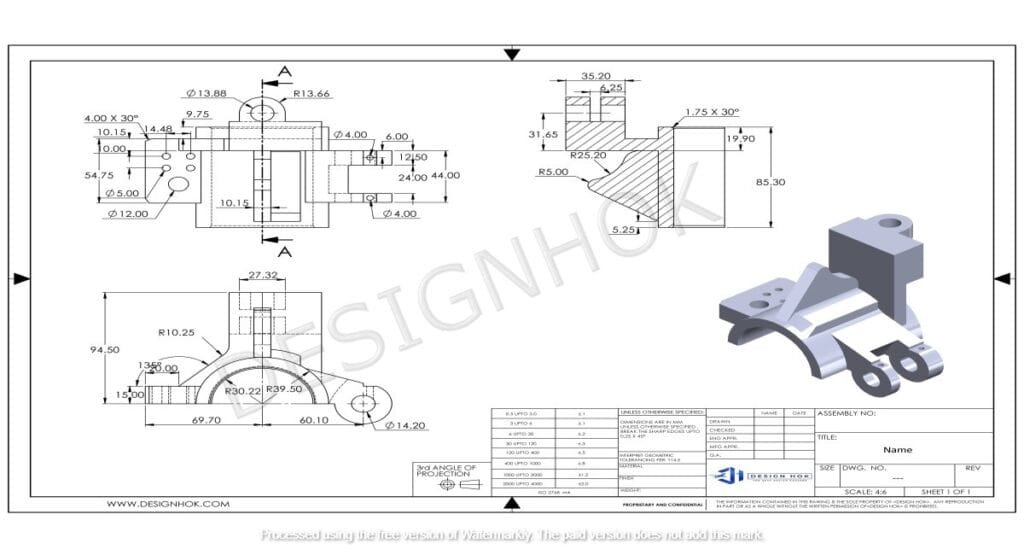

- 2D and 3D Drafting

Converting ideas into technical drawings is one of the initial steps in machine design. Drafting provides a detailed view of each machine component, which helps during the manufacturing phase. Precise 2D and 3D drafting is essential for building machines that fit together seamlessly. - 3D Modeling and Rendering

3D models provide a visual representation of the final product, helping engineers and clients to see the design’s complexity and functionality. Rendering can simulate the machine in operation, offering a closer look at how each part will function. - Finite Element Analysis (FEA) and Simulation Testing

FEA and simulations are crucial for predicting machine behavior under various conditions, from load-bearing analysis to heat resistance. These tests are particularly important for machines used in demanding environments, ensuring they can withstand stresses and strains over time. - Material Selection and Prototyping

Selecting the right materials is fundamental to machine durability and efficiency. High-quality design services provide material recommendations based on cost, strength, weight, and resistance to environmental factors. Many also offer prototyping to test the design in real-world applications before mass production. - Consultation and Custom Design

Top services often include one-on-one consultation, allowing clients to communicate specific requirements, understand technical specifications, and receive tailored solutions. Custom design services are ideal for industries with unique operational needs.

Why Invest in Professional Mechanical Machine Design Services?

Investing in professional machine design services allows businesses to create machines that are not only efficient but also robust and built for longevity. Professional designers understand complex design constraints and leverage industry knowledge to build reliable systems. This expertise translates into reduced operational costs, minimized risk of machinery failure, and compliance with regulatory standards—an essential consideration in highly regulated industries.

Conclusion

The importance of reliable, high-quality mechanical machine design services cannot be overstated. From initial conceptualization to detailed 3D modeling and testing, these services offer a comprehensive approach to building machines that are precise, efficient, and tailored to meet the demands of various industries. Selecting the right provider ensures not only the optimal design of machinery but also its long-term reliability, which translates into efficiency and cost savings. As technological advancements continue, the best machine design services remain adaptable and forward-looking, delivering innovative solutions that help businesses stay competitive in their respective markets.

FAQs

Q1: What are the primary benefits of using a mechanical machine design service?

Mechanical design services provide access to experienced engineers, advanced software, and specialized testing methods, ensuring that machinery is well-designed, efficient, and durable. Using such a service also reduces the risk of design flaws and enhances overall performance.

Q2: How long does it take to design a mechanical machine?

The timeline varies based on machine complexity, requirements, and customization needs. Simple designs may take weeks, while complex, custom machinery might require months for thorough development and testing.

Q3: Can machine design services help with prototypes?

Yes, most professional machine design services offer prototyping to test and refine the design before full-scale production. This step is crucial for ensuring the machine functions as intended in a real-world environment.

Q4: How does 3D modeling benefit the machine design process?

3D modeling allows engineers to visualize the entire machine, check for potential issues, and assess how parts interact before physical production. It minimizes errors and provides a clear understanding of the final product.

Q5: What industries benefit the most from mechanical machine design services?

Industries like automotive, aerospace, manufacturing, medical devices, and construction benefit greatly, as these fields require high precision, durability, and efficiency in machinery.