Description:

Explore the advanced product mechanical design services offered by Design HOK, specializing in creating efficient, innovative, and highly precise designs that meet client needs. This article delves into how Design HOK’s approach to mechanical design emphasizes quality, functionality, and technological integration. From custom 3D modeling to detailed 2D engineering, discover how Design HOK’s expertise can support your product vision and manufacturing goals.

INTRODUCTION:

Product mechanical design is a foundational component in transforming ideas into real, tangible products. For Design HOK, the goal is not only to meet industry standards but to exceed client expectations through innovative, highly detailed, and functionally efficient designs. Specializing in custom mechanical solutions, Design HOK offers clients the advantage of cutting-edge technology and skilled expertise, ensuring that every aspect of the design aligns with the end-use and manufacturing goals. The critical components and services provided by Design HOK, highlighting the value of each phase in the product design lifecycle.

The Role of Product Mechanical Design Services in Modern Manufacturing

The role of mechanical design is more significant than ever, given today’s demand for sustainable, precise, and performance-driven products. Product mechanical design is essential for shaping the structural, functional, and aesthetic aspects of any product. Design HOK’s approach ensures that every part, down to the smallest detail, is well-considered, allowing products to function seamlessly while remaining cost-effective and durable.

Why Choose Design HOK for Product Mechanical Design Services?

Design HOK offers product mechanical design services that integrate innovative design techniques with the latest in engineering technologies. Their team of experienced engineers specializes in crafting designs that adhere to strict industry standards while ensuring the product’s durability, efficiency, and ease of manufacturing.

From initial concept sketches to prototype-ready designs, the process involves a sequence of steps ensuring all aspects are considered, from material choice to structural strength and environmental impact. The integration of advanced software enables Design HOK to deliver accurate simulations and 3D renderings, allowing clients to visualize the product long before it reaches the production phase.

Core Product Mechanical Design Services Offered by Design HOK

1. Concept Development and Design Analysis

Before jumping into the intricacies of a product, Design HOK starts with concept development to ensure that the product vision aligns with the client’s goals. This phase involves:

- Feasibility Studies: Understanding whether the initial idea can be practically achieved with current technology and within the client’s budget.

- Requirement Analysis: Identifying specific functional, structural, and aesthetic requirements, so the design will perform as intended.

2. 3D Modeling and Virtual Simulation

Design HOK employs state-of-the-art 3D modeling software to provide clients with accurate, detailed models of their products. The benefits of this service include:

- Accurate Visual Representation: 3D models allow clients to visualize the final product, facilitating early feedback and adjustments.

- Simulation Testing: Before physical prototyping, Design HOK performs simulations to test the model’s performance under real-world conditions, helping predict issues and optimize design.

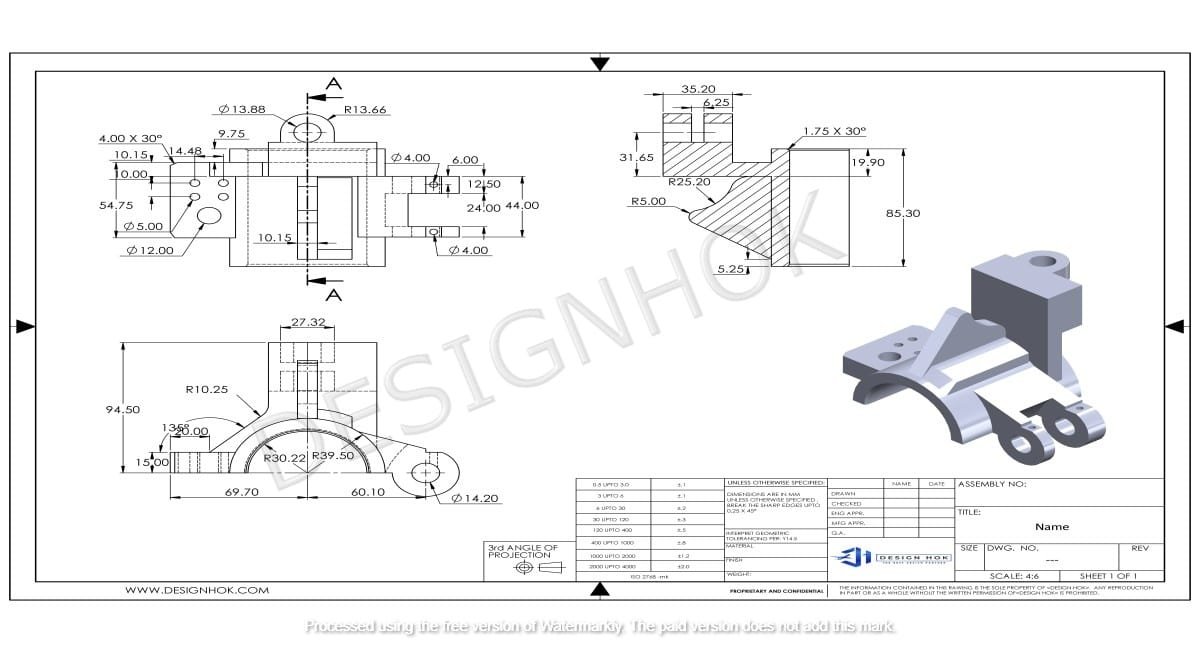

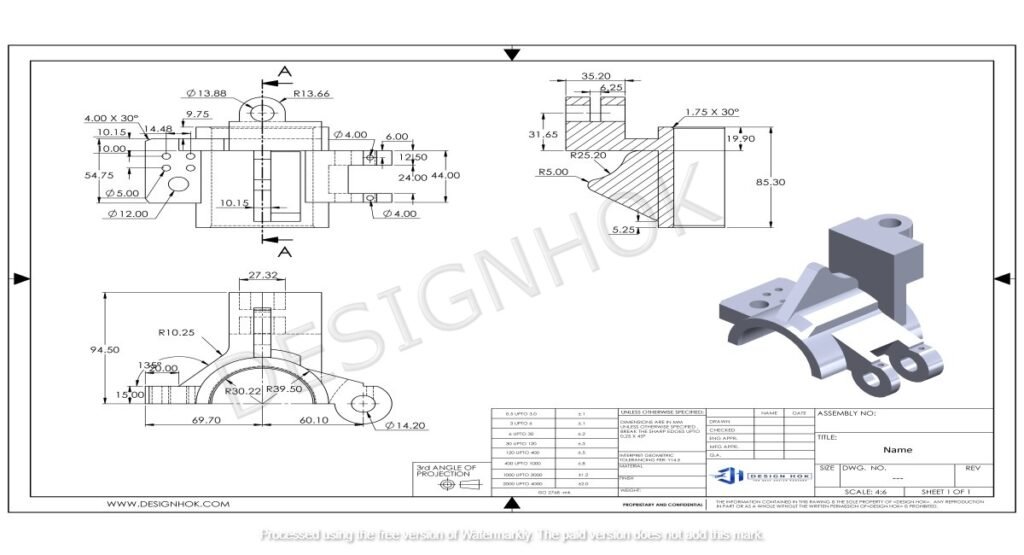

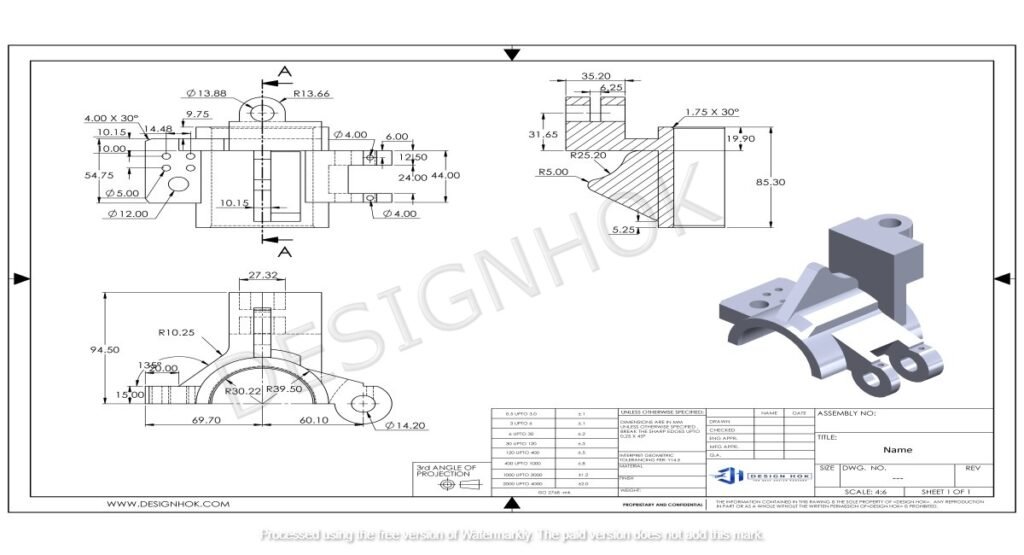

3. Detailed Engineering and 2D Drafting

With precise 2D drafting, Design HOK ensures all mechanical elements and specifications are clearly documented, which serves as a blueprint for manufacturing. This includes:

- Detailed Part Drawings: Each part is represented with exact measurements, ensuring compatibility and functionality.

- Assembly Instructions: Drafting includes assembly guidelines, simplifying the manufacturing process and reducing production errors.

4. Prototype Development and Testing

For clients seeking a physical representation of their product, Design HOK offers prototyping services. These prototypes serve as a tangible version for testing and evaluation, where clients can examine the feel, fit, and performance of the product in a real-world context.

5. Optimization and Finalization

Once the prototype is approved, Design HOK’s team optimizes the design for efficiency, ensuring it meets manufacturing standards and cost-effectiveness. During this phase, modifications are applied to improve performance, simplify the production process, and reduce material usage, which often results in lower production costs without sacrificing quality.

Advantages of Design HOK’s Product Mechanical Design Services Approach

Design HOK’s commitment to detail and precision distinguishes its product mechanical design services. The ability to deliver clear 2D drafts, realistic 3D models, and functional prototypes accelerates the product’s journey from concept to market. Additionally, Design HOK’s expertise extends to cross-disciplinary projects, combining mechanical engineering with electronics, software, and industrial design.

Industries Served by Design HOK

Design HOK’s mechanical design services span various industries, including:

- Automotive

- Consumer Electronics

- Aerospace

- Medical Devices

- Industrial Machinery

Their industry experience enables them to understand specific sector challenges, making them adaptable to diverse requirements across different fields.

Conclusion

Design HOK’s Product Mechanical Design Services stand out for their depth, versatility, and commitment to excellence. With a robust process from initial concept development to prototype testing and optimization, Design HOK is prepared to handle projects of any scale and complexity. By combining technology, creativity, and precision, they help clients achieve their vision with designs that perform seamlessly in real-world applications.

Whether you need a new product designed from scratch or wish to enhance an existing product, Design HOK’s expertise and dedication can provide the solutions necessary to bring your ideas to life. Let Design HOK take your concepts and transform them into functional, manufacturable products that exceed expectations in quality and innovation.

Frequently Asked Questions (FAQ)

1. What is the typical timeline for a mechanical design project with Design HOK?

The timeline varies depending on the complexity and scope of the project. However, an initial timeline and milestones are established at the project outset to ensure transparency and keep progress on track.

2. How does Design HOK ensure that designs are production-ready?

Design HOK conducts thorough testing and simulation during the 3D modeling phase. This includes strength testing, thermal analysis, and motion studies to identify potential issues. Additionally, prototypes are created for hands-on evaluation, ensuring the design meets production standards.

3. Can Design HOK assist with redesigning or optimizing an existing product?

Yes, Design HOK offers redesign and optimization services to improve performance, reduce production costs, or adapt a product to new market demands. They analyze the existing design and suggest enhancements to make it more efficient and functional.

4. Does Design HOK offer support during the manufacturing phase?

Yes, Design HOK offers support beyond the design phase by providing documentation, assembly guidelines, and consultation to ensure the manufacturing process runs smoothly.

5. What industries does Design HOK specialize in?

Design HOK has experience across various sectors, including automotive, consumer electronics, aerospace, medical devices, and industrial machinery, tailoring its design approach to meet the specific needs of each industry.