INTRODUTION:

Mechanical machine parts are made of many components that work together. The machine can do its task only when the parts work together. So, we must understand these parts to know the functionality of machines in daily life.

Machines have been around for centuries. From pulleys and levers to engines and factory machines, they all rely on these parts. They transfer energy, control motion, and make tasks easier. In this article, we’ll look at key mechanical parts and their uses.

Key Mechanical Machine Parts

1. Gears

Gears move power between rotating parts. They can change speed, torque, and direction. Spur gears are in clocks. Helical gears are in car gearboxes. Many machines could not function properly without gears. You can reduce noise and make them last longer by oiling them.

2. Bearings

Bearings reduce friction. You can easily rotate parts using bearings. They are used in small tools at home or in big machines. There are different types of bearings, like ball, roller, and thrust bearings, that have different functions. Good bearings make machines last longer.

3. Shafts

Shafts allow the movement of power from one part to another. They are used in various engines and turbines. Shafts must be strong and straight. If they wear out or bend, machines lose efficiency. This is the reason that shafts play an important role in keeping machines effective.

4. Springs

Springs store and release energy. Compression springs are in car suspensions. You can move things using torsion strings. So, you are able to minimize shock, keep things intact, and help parts work smoothly. They are used in small devices as well as large machines. So, they make your work easier.

5. Pulleys

Pulleys change the direction of force, which allows you to lift things. You can easily lift heavy loads with a pulley. If you use a number of pulleys, then you can reduce your effort. Many machines use pulleys, such as cranes, elevators, and gyms. Pulleys are made of various materials like plastic, metal, or wood. It depends on the load and purpose. So, pulleys are a very important part of mechanical systems.

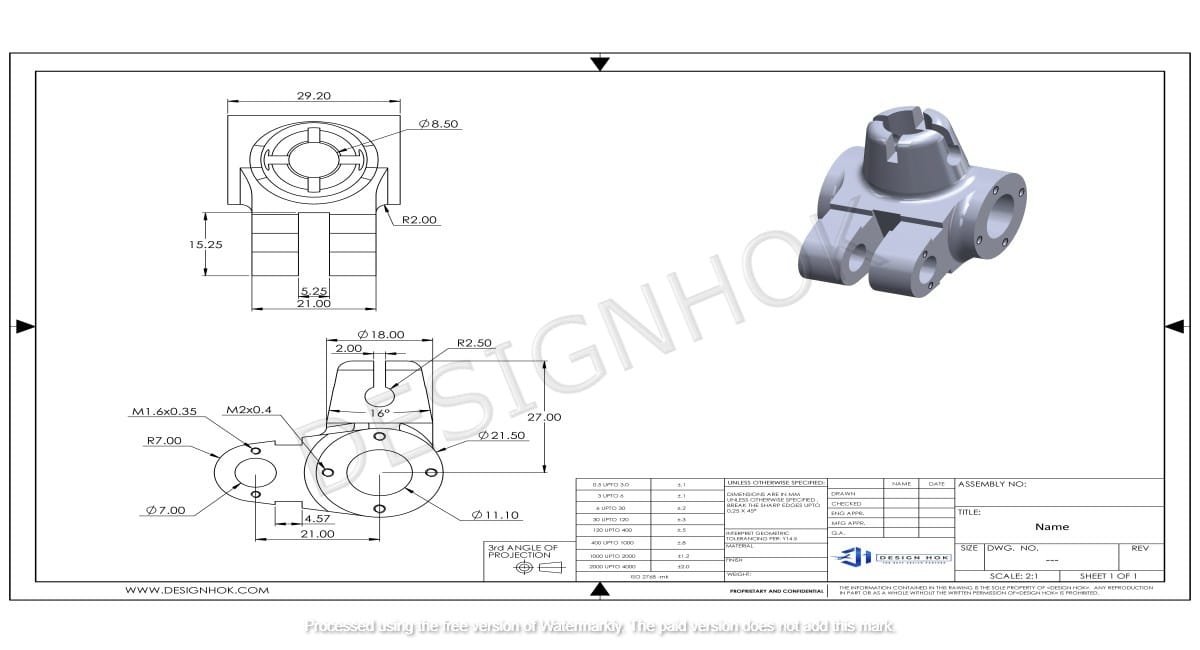

6. Couplings

Couplings contain 2 rotating rods to pass power from one to another. They allow you to connect two shafts in various ways. So, they protect the machine from damage. Moreover, they make sure power runs smoothly. There are various types of couplings, like rigid or flexible couplings. They make sure that the machine works smoothly.

7. Links and Belts

You can move parts with belts by changing the motion from one part to another. Chains are stronger and used in bikes or motorcycles. Both carry motion and power across distances. Belts are used in fans, sewing machines, etc. However, chains are used in bicycles or industrial machinery.

8. Fasteners

You can connect parts and keep them in place using fasteners. They keep machines stable and safe. Without fasteners, machines would fall apart under pressure. There are a variety of fasteners. You use bolts and nuts for heavy machinery and screws for smaller parts.

Conclusion

Mechanical machine parts are the base of modern machines. We know that every part of a machine has its own task. When all the parts work together, you can make the machines run. You must know how they work to do proper design, repair, and use. In the coming decades, it will become even more important to understand the mechanical machine parts.

FAQs

1. What do gears do?

They help to move power from one part to another. So, they manage how fast something moves or the strength of the turning force.

2. What is the importance of bearings?

They minimize friction and let the machines work smoothly.

3. What is the benefit of using pulleys?

They make lifting loads easier by changing the direction.

4. What is the use of couplings?

They connect shafts and allow power transfer even with small misalignments.

5. Why are fasteners needed?

They are used to join the parts of a machine. Moreover, they keep them in place.

7. What do mechanical machine parts include?

There are a number of mechanical machine parts, which are fasteners, gears, pulleys, etc.

8. Name a machine that combines mechanical parts with electrical parts?

An instrument that connects mechanical parts with electrical parts is an electromechanical assembly.

Undeniably imagine that which you said. Your favorite justification appeared to be on the web the easiest factor to consider of.

I say to you, I definitely get irked while other people consider

concerns that they plainly don’t understand about.

You controlled to hit the nail upon the highest as well

as defined out the entire thing with no need side effect ,

people can take a signal. Will likely be again to get more.

Thank you

I am not sure where you’re getting your info, but good topic.

I needs to spend some time learning much more or understanding more.

Thanks for great info I was looking for this information for my mission.

I appreciate your feedback. I’m happy the subject was useful and pertinent to you. I hope the information continues to support your research and mission, so feel free to explore at your own pace.

Thank you! I’m glad you found the information useful. Take your time exploring, and feel free to dive deeper—I’m regularly adding more detailed content that could help with your mission. Hope to see you back soon for more insights!

Hi there to all, how is all, I think every one is getting more from

this website, and your views are fastidious for new viewers.

Hello I am so grateful I found your website,

I really found you by accident, while I was browsing on Google for something else, Anyways I

am here now and would just like to say thank you for a remarkable post and a all round exciting blog (I also love the theme/design), I don’t have time to browse it all at the minute but

I have saved it and also included your RSS feeds, so when I have

time I will be back to read a great deal more, Please do keep up the excellent job.

I sincerely appreciate your nice remarks. Thank you so much for sharing this. I’m happy the post was useful to you and that you liked the design. When someone finds the website and finds value in it, it is always wonderful to hear. We appreciate you subscribing to the RSS feed and saving it. When you have more time to explore, I hope to see you again. Your assistance is greatly appreciated.

Thanks!!!