Introduction

Mechanical machine learning is a branch of Artificial intelligence and is affecting how industries work. It requires both accuracy and the ability to adapt. That is why you can use it in several fields like construction, cars and airplanes. Now companies need better tools to create designs that are faster and smarter. Design Hok is among the companies that use this approach.

Now, machine learning algorithms are used to figure out patterns and make decisions. So, it allows you to work faster, spend less, and improve your results. Mechanical machine learning for Design HOK adds efficiency and creativity to architectural and engineering projects.

The Role of Mechanical Machine Learning for Design HOK

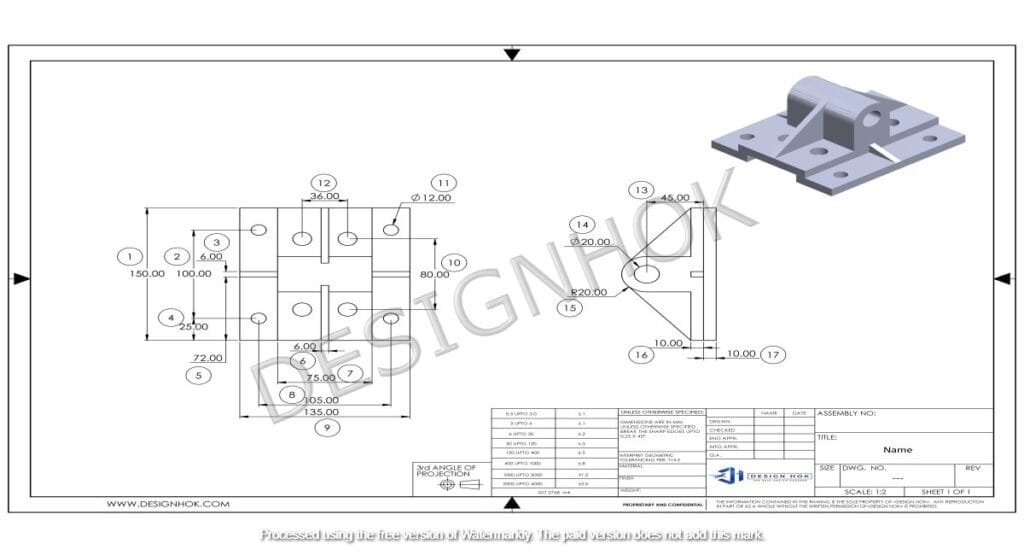

Machine learning helps engineers handle everyday tasks, review old data, and provide knowledge about the future. You have to feed project history into the models. This allows engineers to foresee risks, weak areas, and make future designs better. So, this results in quick decision-making and minimizes errors.

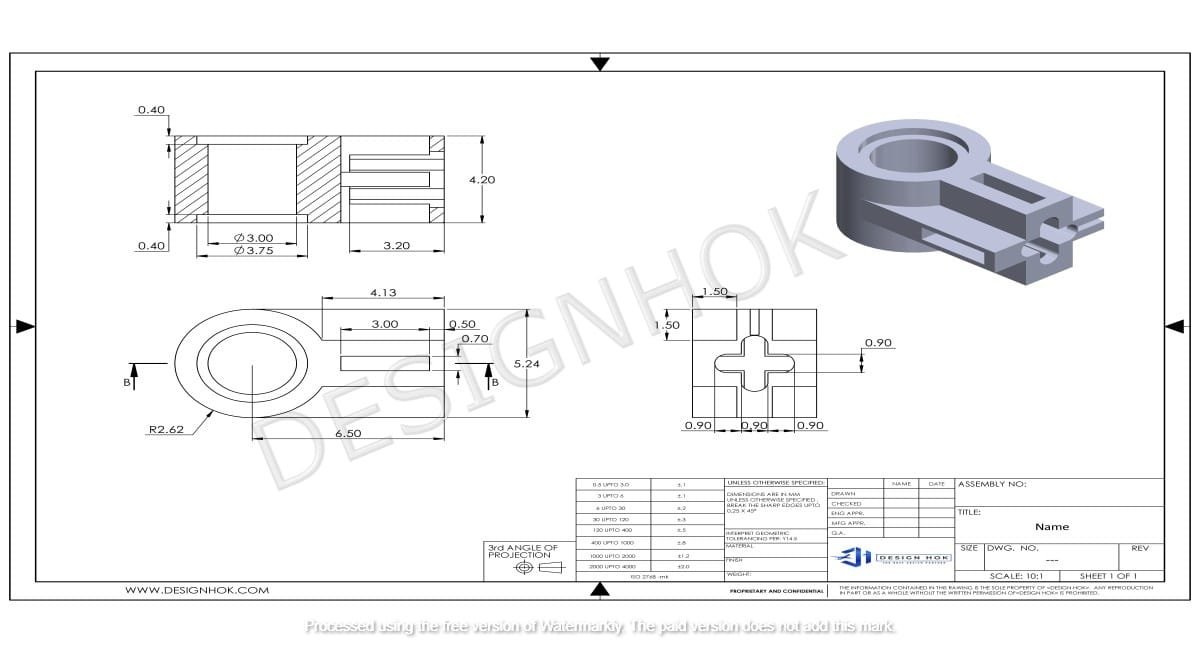

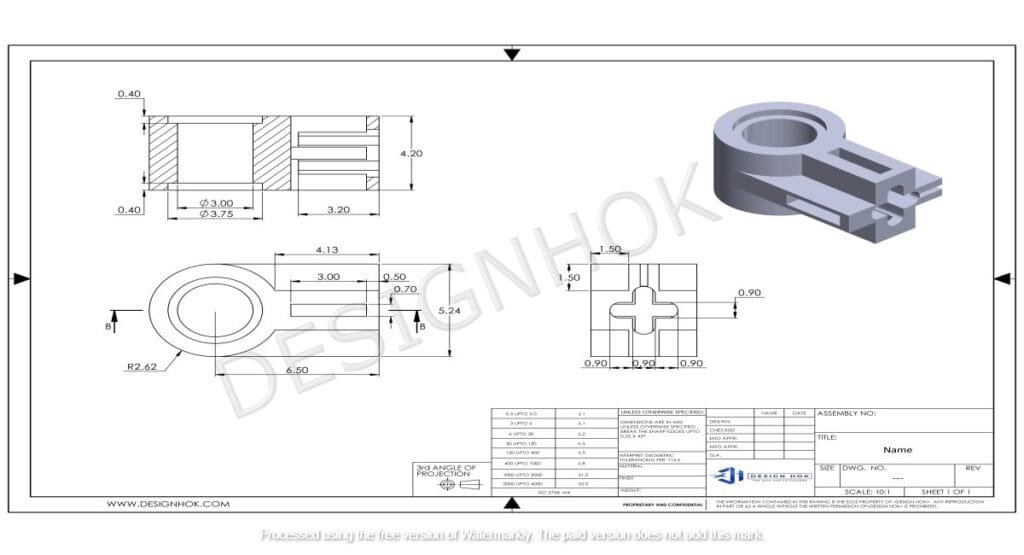

Machine learning helps you to try different designs for gears, motors, and other parts. So, it saves material, makes parts stronger, and avoids failures. For firms like Design HOK that have to work on big construction and infrastructure projects, this level of accuracy is very useful.

Enhancing Mechanical Machine Learning for Design HOK with Predictive Analytics

One of the benefits of machine learning is predictive analysis. These models are able to predict the performance of new systems by understanding past designs and repairs. Engineers are able to identify failures before making a sample.

This is very important in case of heavy loads, stress, or heat. So, machine learning tools assist you in getting quick results and better designs.

Design Hok uses these tools in projects like large infrastructures and HVAC systems. That is why machine learning is useful, as it allows you to create better designs that are friendly for the environment.

Optimizing Mechanical Machine Learning With Automation

Machine learning enables you to automate your tasks. These tasks include material choice, part sizing, and checking structures. So, this results in increased productivity by saving time.

You are able to work consistently and minimize errors with the help of automation.

For example, machine learning assists in HVAC systems by choosing the right parts. So, automating mechanical machine learning at Design Hok saves time for complex projects at Design Hok.

Hurdles and Chances

Even with its benefits, mechanical machine learning has challenges. Models need a large amount of data to be trained. Moreover, data must be of good quality to ensure accurate results. In order to apply machine learning in engineering a mix of both AI and mechanics is required. However, many firms are unable to do it.

There will be more opportunities in the future as more engineers learn these skills. Now companies, including Design Hok, are using both their expertise in design and AI to be more innovative.

Summary

Mechanical Machine Learning for Design HOK is reshaping how engineers design systems. You are able to tell your performance in the future. Moreover, you can reduce costs and automate tasks with the help of machine learning. Design Hok uses it for faster, smarter, and better solutions. In the future, the use of machine learning in mechanical design will be common. This helps engineers have more control to create better and sustainable projects.

FAQ:

1. What is mechanical machine learning?

Mechanical machine learning means using machine learning methods for mechanical engineering. You are able to automate tasks, tell the outcomes, and improve designs. This results in increased productivity and better designs.

2. What is the advantage of using machine learning in mechanical engineering?

You are able to minimize errors, predict behavior, and lower material waste. Moreover, it also saves your time.

3. What is the use of mechanical machine learning in HOK’s projects?

At Hok, we are able to make our designs better with predictive analysis, automation, and system development.

4. What are the main hurdles?

You require good-quality data and a combination of AI and engineering knowledge.

5. Will it bring future opportunities?

Yes, it will offer new chances to use better materials. Build stronger systems and design environmentally friendly projects.

6. Is it better to learn machine learning as a mechanical engineer?

Yes, it is quite useful to learn machine learning for mechanical engineers. You can do modeling, optimization, and data analysis with the help of machine learning.