Description:

Explore how 3D Rendering of Parts transforms design workflows at DesignHok. This blog highlights its benefits, applications, and how it enhances communication, precision, and innovation in engineering projects.

In the evolving world of engineering and product development, visualizing a concept before it’s manufactured is crucial. At DesignHok, we harness the power of 3D Rendering of Parts to bridge the gap between imagination and realization. This digital process transforms basic models into lifelike visuals, allowing designers, clients, and manufacturers to see how parts will appear and function in the real world. Whether it’s for mechanical components, prototypes, or complete assemblies, 3D rendering has become a vital asset in the design process.

Let’s dive into what 3D Rendering of Parts means, its significance in engineering, and why DesignHok leverages this technology to deliver high-quality design solutions.

What Is 3D Rendering of Parts?

3D Rendering of Parts refers to the process of creating photorealistic or visually accurate images from a 3D model of a part or component using rendering software. This process involves adding textures, lighting, shadows, colors, and environmental settings to give a realistic appearance to a digital design. It goes beyond just modeling—it provides a lifelike preview of the final product.

These renderings are often used in project presentations, manufacturing discussions, client approvals, and marketing materials. For DesignHok, 3D Rendering of Parts is not just a design step—it’s a visual communication tool that clarifies details and enhances decision-making.

Why 3D Rendering Matters in Design Projects

Traditional 2D drawings and even basic 3D models often leave room for ambiguity. When stakeholders need to understand complex geometries, materials, finishes, and how parts fit together, 3D rendering becomes invaluable.

At DesignHok, 3D rendered parts help:

- Visualize complex parts with high precision.

- Improve communication between design teams and clients.

- Reduce design errors before production begins.

- Accelerate approvals by showcasing lifelike previews.

- Support marketing by offering realistic images of a product before manufacturing.

Whether it’s a mechanical gear system, housing unit, or electronic casing, rendered images provide clarity that traditional methods simply can’t match.

Applications of 3D Rendering at DesignHok

DesignHok works across various sectors—automotive, industrial design, consumer electronics, and machine components. Here’s how we use 3D rendering of parts in real-world scenarios:

1. Mechanical Design Projects

When developing parts for machines or equipment, 3D Rendering of Parts reveal stress points, moving interfaces, and design aesthetics. This is crucial for identifying potential failures early in the process.

2. 3D Modeling Projects

After building a 3D CAD model, our team enhances it with textures, lighting, and material finishes. This gives clients a clear understanding of what to expect before investing in a prototype or final product.

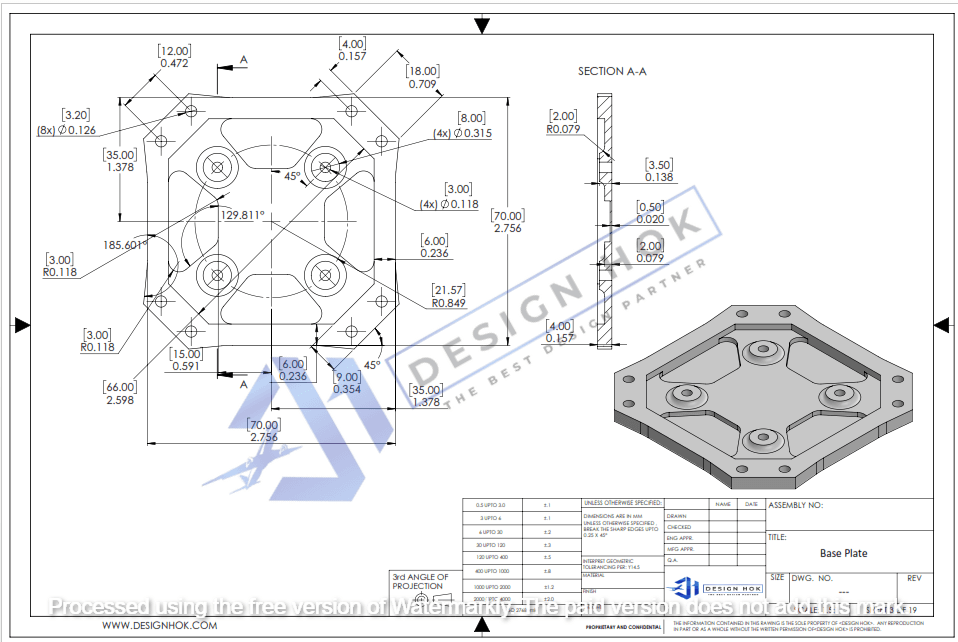

3. 2D Drafting to 3D Transition

Often, we convert 2D technical drawings into 3D renderings. This brings older blueprints to life and helps teams modernize their design workflows.

4. Client Presentation and Proposals

Our clients often need visual aids for stakeholders, investors, or customers. Rendered parts make presentations visually appealing and technically sound, which helps secure funding or approvals.

The DesignHok 3D Rendering Process

We follow a well-defined workflow that ensures high-quality output with precision:

- Requirement Analysis: We start by understanding the client’s goals, part functions, dimensions, and materials.

- 3D Modeling: Using software like SolidWorks, Autodesk Inventor, or Fusion 360, we create accurate 3D models.

- Rendering Setup: We import the model into rendering tools such as KeyShot or Blender, applying textures, environments, and lighting.

- Final Rendering: High-resolution images or animations are created and optimized for use in presentations or documentation.

- Client Review & Revisions: Clients provide feedback, and we refine the renderings as needed for the final delivery.

Benefits of 3D Rendering for Clients

At DesignHok, our clients enjoy numerous benefits from integrating 3D Rendering of Parts into their design pipeline:

- Enhanced Visualization: See how parts will look and behave in the real world.

- Time and Cost Efficiency: Reduce errors before manufacturing, saving time and production costs.

- Faster Decision-Making: Stakeholders can make quicker, more informed decisions.

- Improved Collaboration: Teams can align better when everyone understands the product visually.

- Stronger Marketing Tools: Use renderings for promotional material, product launches, or client brochures.

Software and Tools We Use

DesignHok combines industry-leading tools to ensure outstanding rendering quality:

- SolidWorks – for precision part modeling

- Autodesk Fusion 360 – for integrated CAD and rendering workflows

- KeyShot – for photorealistic rendering

- Blender – for customizable animations and advanced lighting

- Photoshop – for post-processing and visual enhancement

These tools help us stay ahead of industry standards and meet diverse client needs.

Future of 3D Rendering in Engineering

The future of 3D rendering is advancing with real-time rendering, virtual reality (VR), and augmented reality (AR) integration. At DesignHok, we’re exploring interactive renderings where clients can rotate, zoom, or explode-view parts in real-time using VR headsets or web interfaces.

As digital twins and Industry 4.0 evolve, rendered parts will play an even more significant role in digital product development.

Conclusion

3D rendering of parts is more than just making a product look good—it’s about enhancing clarity, reducing risk, and enabling innovation. At DesignHok, our approach to 3D Rendering of Parts combines technical expertise with creative presentation to deliver stunning visuals that drive smarter decisions.

Whether you’re developing a new product, reimagining an existing design, or preparing a prototype, our team ensures your parts are not just modeled—but truly brought to life. With the power of 3D rendering, your vision becomes real even before production begins.

Frequently Asked Questions (FAQ)

Q1: What industries can benefit from 3D Rendering of Parts?

A: Almost every industry—automotive, aerospace, consumer goods, industrial equipment, electronics, and architecture—can benefit from 3D rendering. It enhances design communication and accuracy.

Q2: What’s the difference between 3D modeling and 3D rendering?

A: 3D modeling involves creating the shape and structure of a part, while 3D rendering focuses on creating a lifelike visual of that model using textures, lighting, and environment settings.

Q3: How long does a 3D rendering project take at DesignHok?

A: It depends on the complexity of the part and the level of detail required. Simple parts may take a day or two, while complex assemblies or animations may take several days to complete.

Q4: Can I use 3D rendered images for marketing or product launches?

A: Absolutely. Our high-resolution renderings are perfect for brochures, websites, investor decks, and product catalogs.

Q5: Do you offer revisions after the rendering is done?

A: Yes, we provide revisions based on client feedback to ensure complete satisfaction and alignment with project goals.

With havin so much content and articles do you ever run into any issues of plagorism or copyright infringement? My site has a lot of exclusive content I’ve either written myself or outsourced but it appears a lot of it is popping it up all over the internet without my permission. Do you know any ways to help protect against content from being stolen? I’d genuinely appreciate it.

Enjoyed reading through this, very good stuff, regards. “Golf isn’t a game, it’s a choice that one makes with one’s life.” by Charles Rosin.

I’m really enjoying the design and layout of your site. It’s a very easy on the eyes which makes it much more pleasant for me to come here and visit more often. Did you hire out a developer to create your theme? Exceptional work!