3D modeling is a newer technique for designing machines. You improve accuracy, save time, and create better vehicles for the companies.

Introduction:

New technology has led to the growth of the car industry. 3D modeling has revolutionized the car industry. Cars and their machines are complicated. It includes engines, brakes, and frames. You have to design each part carefully.

3D modeling makes this easier. Engineers can design detailed models before making it. So, they can experiment with ideas, solve problems, and make the design better.

3D Modeling in Automotive Machines

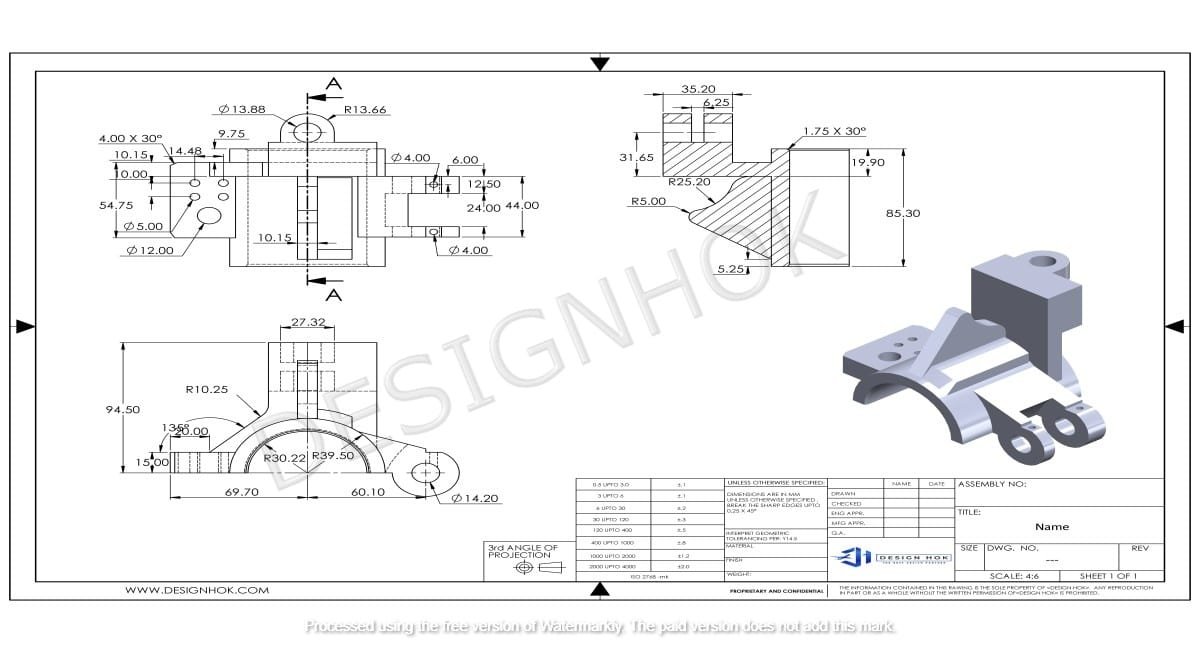

3D modeling is the use of computer software to make digital models of parts. You are able to create real-looking models. So, it allows engineers to experiment with them on screen rather than making physical parts quickly.

You are able to design many car parts using 3D models. These include

- Engines

- Transmissions

- Suspension systems

- Brakes

- Frames and chassis

- Inner parts, including seats and dashboards

These models enable engineers to experiment with strength, performance, and safety. You are able to minimize errors and save time and money.

Major Advantages of 3D Modeling

1. Better Accuracy

Several parts of the car can be attached. You can conduct precise measurements using 3D modeling. Problems like parts clashing can be spotted before building.

You can create designs swiftly using 3D modeling. If you require a new shape or material for a part, then it can be changed quickly. This speeds up the process of launching new vehicles.

3. Testing Digitally

In the past, companies built real prototypes. Testing was slow and costly. Now, engineers use 3D models. They test designs on a computer. They check heat, strength, and airflow quickly.

4. Minimizing Cost and Time

When you make fewer errors, it results in less material waste. Virtual tests mean fewer physical models. This saves money and shortens development time.

5. Easy Teamwork

3D models are easy to share. Designers, engineers, and managers can all view the same model. Everyone understands the design better. This improves teamwork and decision-making.

Uses of 3D Modeling in Automotive Machine Design

1. Engine Design

Engines are complex and need high accuracy. Engineers can inspect how various parts, including pistons and valves, fit together. They can also test fuel use and heat control before building.

2. Suspension and Frame

Suspension is important to maintain the smoothness and safety of a ride. 3D modeling lets engineers to check the behavior of cars under bumps and weight. Frames and chassis can also be checked for strength and lightness.

3. Aerodynamics

The design of a car’s body affects the speed and the fuel efficiency of the car. You can test the flow of air through a body using 3D models. This lowers the drag force and gives better output.

4. Interiors and Comfort

Seats, dashboards, and controls can be modeled in 3D. Engineers test comfort, space, and safety. Virtual reality can also be used to step inside the model before it is built.

5. Printing

3D modeling and 3D printing are linked to each other. After creating a model, you can

print it into a real part. So, it is useful for prototypes as well as final products with complicated shapes.

6. 3D Modeling in the Coming Decades

In the current age, 3d modelling is improving. New tools like artificial intelligence and virtual reality are making it stronger. In the future, cars can be designed faster and tested more deeply.

This will lead to safer, smarter, and more efficient vehicles. Companies will save money and time while giving drivers better performance and comfort.

3D Modeling in the Coming Decades

In the current age, 3d modelling is improving. New tools like artificial intelligence and virtual reality are making it stronger. In the future, cars can be designed faster and tested more deeply.

This will lead to safer, smarter, and more efficient vehicles. Companies will save money and time while giving drivers better performance and comfort.

Conclusion

3D modeling in automotive machines impacts the making and designing of cars. You can design quickly, minimize cost, and improve testing. So, engines and interiors can play an important role in making modern vehicles.

You will require more tools in the future for better 3D modeling. These improvements make cars safer, quicker, and efficient.

FAQs

Q: Explain 3D modeling in car design?

You have to create digital models of parts to experiment and improve designs.

Q: How can you save money through 3D modeling?

It lets you find errors quickly, and you do not need to spend money on actual prototypes.

Q: Can 3D models test performance?

Yes. They can check strength, airflow, and heat in a virtual space.

Q: Can teams work better with 3d models?

Sure, Models can be shared easily, which results in a better understanding of the design.