Description:

In today’s rapidly evolving engineering landscape, 3D modeling plays an indispensable role in mechanical design. At DesignHOK, 3D Modeling for Mechanical Design at DesignHOK is not just about creating visual representations; it is about bringing ideas to life, ensuring precision, and optimizing functionality. This article delves into how 3D modeling enhances mechanical design processes, the tools and techniques employed, and the significant impact it has on project outcomes. Whether you are a designer, engineer, or business looking to explore the world of 3D modeling, this article offers insights that will deepen your understanding of its value in the mechanical design domain.

Introduction:

Mechanical design is at the heart of engineering, and as technology continues to advance, so too does the importance of 3D modeling in the design process. At DesignHOK, our approach to mechanical design leverages cutting-edge 3D Modeling for Mechanical Design at DesignHOK tools to create precise, detailed, and efficient designs. But what makes 3D modeling so vital, and how does it transform the mechanical design process?we explore how 3D modeling shapes mechanical design, its benefits, the software involved, and how it plays a critical role in delivering successful design projects.

What is 3D Modeling for Mechanical Design at DesignHOK?

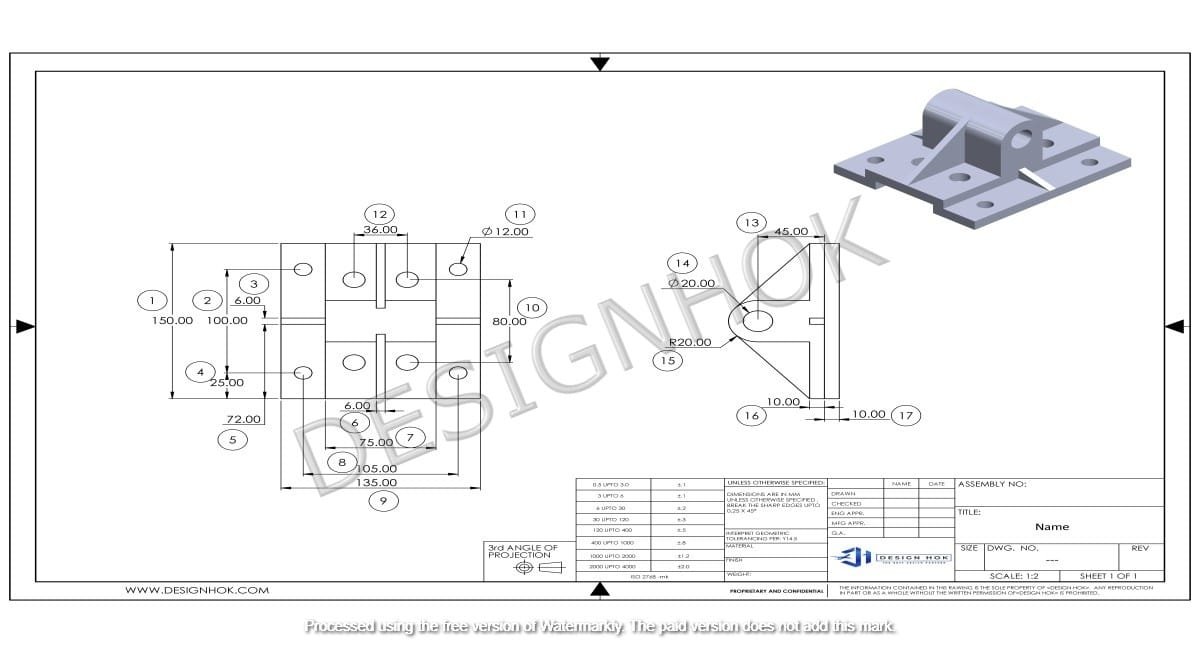

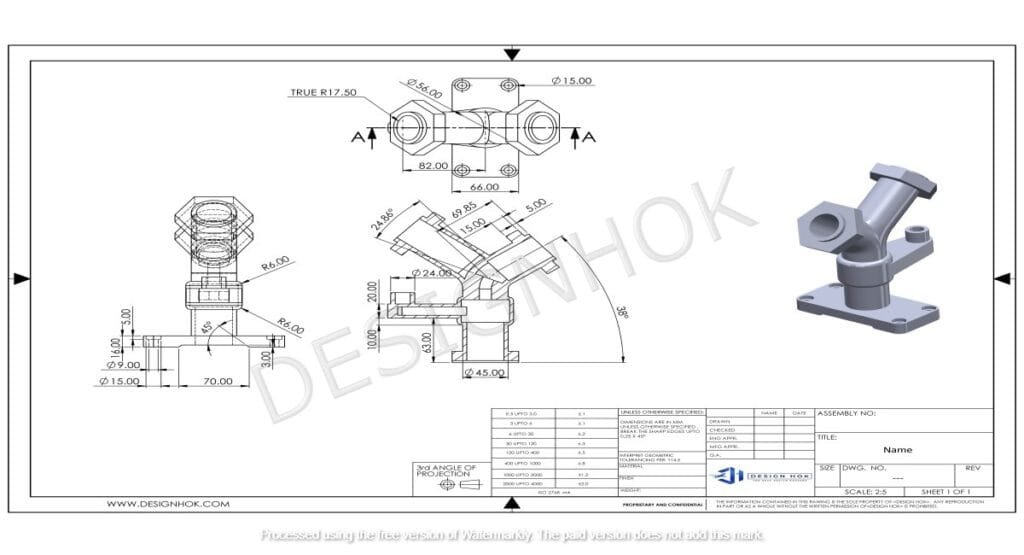

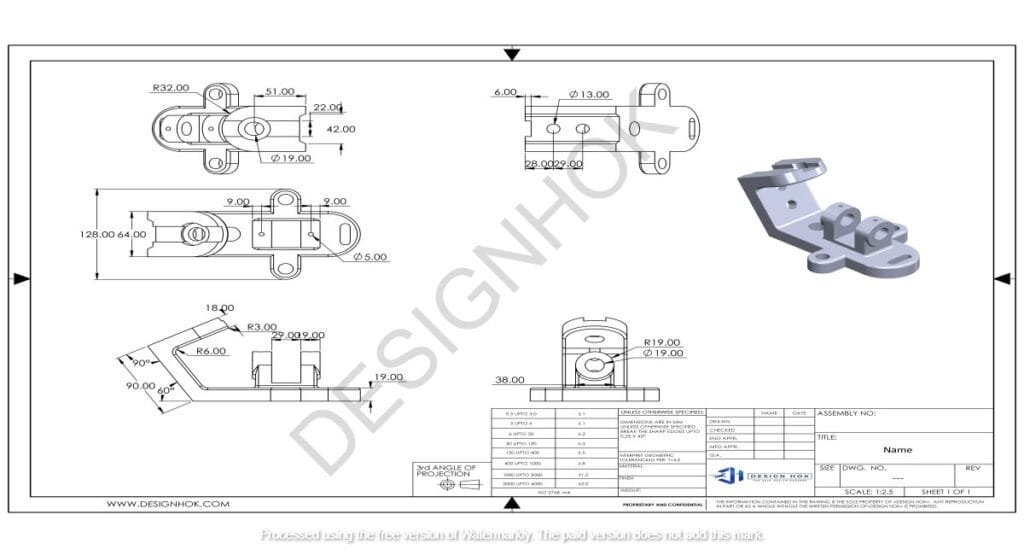

3D modeling refers to the process of creating a three-dimensional representation of a physical object or system using specialized software. In mechanical design, it involves designing mechanical components, assemblies, and systems in a 3D space, enabling engineers to visualize, analyze, and refine their ideas before actual production.

The Importance of 3D Modeling for Mechanical Design

For mechanical engineers at DesignHOK, 3D modeling is indispensable. Here’s why:

- Enhanced Visualization: 3D models provide a clear and comprehensive view of how a design will look and function. This level of detail helps identify potential issues early in the process, reducing errors and rework.

- Precision and Accuracy: 3D modeling ensures that every dimension is accurate and can be precisely translated into manufacturing plans. It eliminates the ambiguities often present in 2D drawings, making it easier to maintain quality control.

- Faster Iteration and Prototyping: 3D models allow for rapid iteration of designs. Engineers can easily make changes, test different configurations, and simulate performance, speeding up the prototyping process.

- Cost Reduction: By reducing the number of physical prototypes and minimizing errors, 3D modeling helps cut down on material waste and production costs.

Key Software Tools Used for 3D Mechanical Modeling

At DesignHOK, we use several advanced 3D modeling software tools to create detailed and accurate mechanical designs. Some of the leading software we rely on includes:

1. SolidWorks

SolidWorks is one of the most popular CAD software platforms used for 3D mechanical design. It offers comprehensive tools for part modeling, assembly modeling, and simulation. With SolidWorks, designers can create detailed mechanical components and assemblies and test their performance virtually.

2. Autodesk Inventor

Autodesk Inventor is another powerful tool used at 3D Modeling for Mechanical Design at DesignHOK. Known for its intuitive user interface and robust design capabilities, it allows engineers to create complex parts and simulate real-world conditions.

3. CATIA

CATIA is a highly sophisticated software developed by Dassault Systèmes, used extensively in industries like aerospace, automotive, and industrial design. It offers advanced features for 3D modeling and simulation, making it a favorite for highly intricate mechanical designs.

4. PTC Creo

PTC Creo is another robust tool used for 3D mechanical modeling, offering a wide range of features for part design, sheet metal design, and parametric modeling. It’s known for its flexibility and ability to handle complex assembly models.

Steps in the 3D Modeling for Mechanical Design at DesignHOK

The process of creating a 3D Modeling for Mechanical Design at DesignHOK involves several key steps:

1. Conceptualization and Sketching

Every project begins with brainstorming and conceptual sketches. Engineers and designers come together to understand the project’s requirements and constraints, sketching out rough ideas before moving to digital modeling.

2. Creating the 3D Model

Once the concept is clear, the team begins to create the 3D model using CAD software. At this stage, the design takes shape, and the components are modeled in three dimensions.

3. Simulation and Analysis

After the initial model is created, it undergoes simulations to test its performance. This step helps identify any flaws in the design or structural weaknesses that need to be addressed before moving forward.

4. Refinement and Optimization

Based on simulation results, designers refine and optimize the 3D model. This can involve tweaking dimensions, improving material choices, or altering components to enhance functionality or reduce costs.

5. Finalization and Manufacturing Plans

Once the design is finalized, detailed manufacturing plans and technical drawings are generated. These are used for production, ensuring that every detail is accurately conveyed to the manufacturing team.

Benefits of 3D Modeling for Mechanical Design at DesignHOK

1. Improved Communication

3D models act as a universal language, improving communication among engineers, designers, and clients. They allow for clear and direct communication, ensuring everyone is on the same page and understands the project’s requirements.

2. Enhanced Collaboration

Since 3D models can be shared digitally, team members from different locations can work collaboratively on the same design. This facilitates teamwork, even in remote work environments.

3. Better Decision-Making

With a 3D model, stakeholders can make more informed decisions. The model provides a clear understanding of how the design will look and function, enabling better choices in materials, manufacturing methods, and design alterations.

4. Reduced Risk and Errors

By visualizing the entire design in 3D, engineers can anticipate potential problems early in the design process. This proactive approach significantly reduces the risk of costly errors during manufacturing.

How3D Modeling for Mechanical Design at DesignHOK

One of the most significant advantages of 3D modeling is its ability to save both time and costs. Here’s how:

- Quick Revisions: If a design needs changes, it’s easy to update the 3D model, rather than redoing physical prototypes or making changes to 2D drawings.

- Fewer Prototypes: Physical prototypes are costly and time-consuming. With 3D modeling, engineers can test designs virtually, reducing the need for multiple prototypes.

- Error Reduction: Mistakes can be costly in mechanical design. 3D modeling allows for a more thorough review and correction of errors before production, which helps save time and money.

Real-World Applications of 3D Modeling in Mechanical Design

At DesignHOK, we apply 3D Modeling for Mechanical Design at DesignHOK in a wide range of mechanical design projects. Some common applications include:

- Product Design: Designing consumer products such as electronic gadgets or automotive parts.

- Tool Design: Creating detailed models for industrial tools and equipment, ensuring they meet performance and safety standards.

- Machine Design: Developing complex machinery and mechanical systems for industries such as manufacturing and aerospace.

The Future of 3D Modeling for Mechanical Design at DesignHOK

The future of 3D modeling in mechanical design looks bright, with advancements in artificial intelligence, augmented reality, and additive manufacturing paving the way for more innovative and efficient designs. As technology continues to evolve, 3D modeling will play an even more pivotal role in shaping the future of mechanical engineering.

Conclusion

3D modeling is a game-changer in mechanical design, offering countless benefits from enhanced accuracy to improved collaboration. At DesignHOK, we leverage the power of 3D modeling to deliver designs that are not only precise but also efficient and cost-effective. By embracing cutting-edge tools and techniques, we are able to push the boundaries of design and engineering, ensuring that every project is a success.