3D Modeling for Machine Part Design by enhancing precision, improving efficiency, and streamlining the engineering process. Learn the benefits, applications, and importance of 3D modeling in the creation of mechanical components.

Introduction:

The Role of 3D Modeling in Modern Machine Part Design

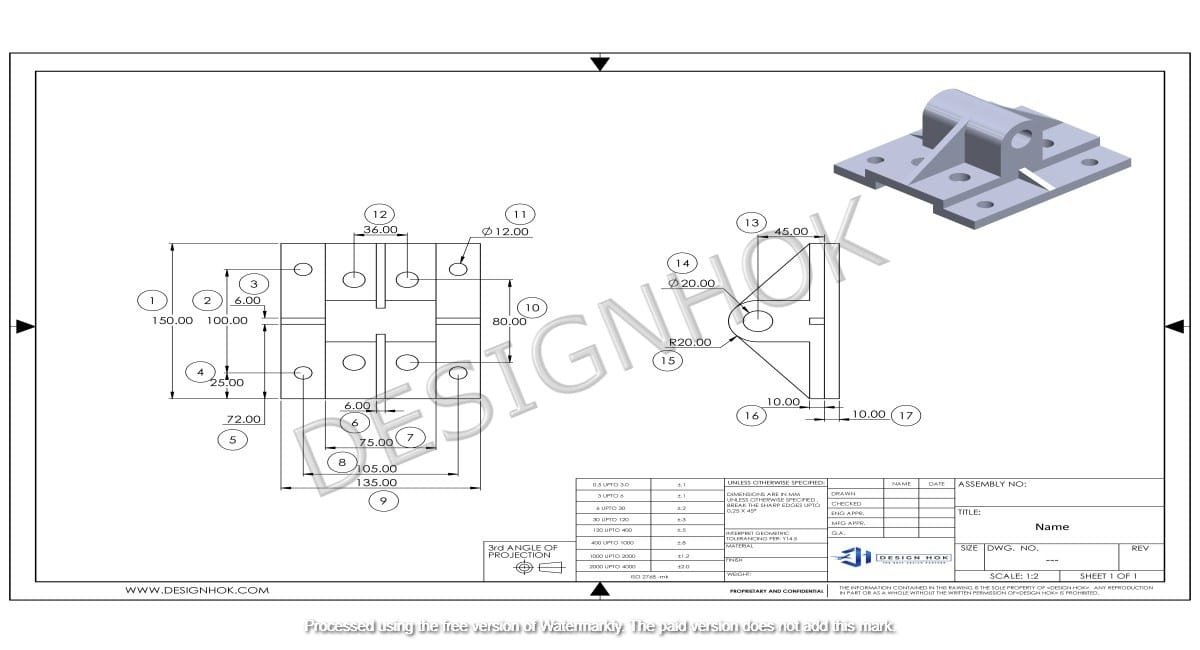

In the world of 3D Modeling for Machine Part Design and manufacturing, designing machine parts is a complex process that requires a high level of precision, efficiency, and attention to detail. Traditional design methods, such as 2D drawings, have limitations that can lead to errors and inefficiencies. However, the advent of 3D modeling has revolutionized machine part design by offering more accurate, flexible, and streamlined processes. 3D modeling not only allows engineers to visualize and test parts before production but also helps reduce costs and minimize errors.

This blog will explore the significance of 3D Modeling for Machine Part Design, its applications, benefits, and how it has become an indispensable tool in various industries.

What is 3D Modeling for Machine Part Design?

3D Modeling for Machine Part Design refers to the process of creating a three-dimensional digital representation of machine parts using specialized software. This digital model serves as a virtual prototype, allowing engineers and designers to explore the part’s structure, dimensions, materials, and interactions with other components. By simulating the part in a digital environment, engineers can optimize the design before creating physical prototypes or moving to mass production.

Several techniques are used in 3D Modeling for Machine Part Design including:

- Solid Modeling: This technique focuses on creating a detailed model that defines the volume, surface, and mass of the part. Solid modeling is widely used for machine parts because it offers a high level of accuracy and can simulate physical properties like weight and material strength.

- Parametric Modeling: This approach allows designers to set specific parameters (such as dimensions or material properties) and automatically update the model when those parameters are adjusted. It’s particularly useful in iterative design processes, where changes are frequently made.

- Surface Modeling: This technique is used to create detailed surfaces of complex parts. It’s typically applied in cases where surface accuracy is critical, such as in automotive or aerospace part design.

Key Advantages of 3D Modeling for Machine Part Design

1. Enhanced Visualization and Accuracy

3D Modeling for Machine Part Design provides a clear and detailed representation of machine parts. Unlike 2D drawings, which are limited to flat views, 3D models allow designers to rotate, zoom, and view parts from any angle. This improved visualization ensures that every aspect of the part is accounted for, reducing the risk of missing important details. Additionally, 3D modeling tools provide highly accurate dimensions and tolerances, leading to a more precise design that closely matches the intended product.

2. Faster Iterative Design

The design process often involves multiple iterations, with changes being made to dimensions, materials, or part geometry. 3D Modeling for Machine Part Design for Machine Part Design allows engineers to quickly make these changes and see the impact in real time. Parametric modeling, in particular, streamlines this process by automatically adjusting related dimensions and features when one parameter is modified. This saves time and reduces the likelihood of errors compared to manually updating 2D drawings.

3. Simulations and Testing in a Digital Environment

One of the most significant benefits of 3D modeling is the ability to test the machine part in a virtual environment before physical production. Engineers can perform simulations to assess the part’s behavior under various conditions, such as stress, heat, and load. These tests can reveal potential issues, allowing engineers to fix them early in the design process, which reduces the need for costly physical prototypes and mitigates the risk of product failure.

4. Improved Collaboration and Communication

3D models make it easier for engineers, designers, manufacturers, and clients to collaborate. The visual nature of 3D models allows all stakeholders to see the design, understand how it works, and provide feedback. This collaboration ensures that everyone is aligned, reducing miscommunication and ensuring the project stays on track. Moreover, design changes can be easily shared and reviewed by all parties, fostering a more cohesive design process.

5. Reduced Costs and Time to Market

By enabling virtual testing and reducing the number of physical prototypes required, 3D modeling significantly lowers development costs. It also speeds up the overall design process, allowing manufacturers to bring products to market more quickly. The time savings achieved with 3D modeling also provide a competitive advantage, as companies can respond faster to market demands and changes.

Applications of 3D Modeling in Machine Part Design

3D modeling is applied across numerous industries, helping to design parts that range from simple components to complex mechanical systems. Here are some common applications:

1. Automotive Industry

The automotive industry relies heavily on 3D Modeling for Machine Part Design components, transmissions, suspension systems, and other parts. Engineers can create detailed models of each part and run simulations to ensure the parts function effectively within the vehicle’s overall system.

2. Aerospace Engineering

In aerospace, precision is critical. 3D Modeling for Machine Part Design is used to design aircraft components such as wings, engines, and landing gear. The ability to test parts in a digital environment helps ensure they meet the rigorous safety and performance standards required in the aerospace industry.

3. Consumer Products

For consumer goods, manufacturers use 3D Modeling for Machine Part Design for appliances, electronics, and tools. By optimizing the part design before production, companies can improve product quality, reduce material waste, and ensure ease of manufacturing.

4. Medical Devices

In the medical field, 3D modeling is used to design implants, prosthetics, and surgical instruments. The precision of 3D models ensures that medical devices are safe, effective, and tailored to the needs of individual patients.

5. Industrial Machinery

For industrial equipment, 3D modeling helps design components such as gears, pumps, and conveyors. Engineers can simulate how these parts will perform in a working environment, optimizing them for durability and efficiency.

Future of 3D Modeling in Machine Part Design

The future of 3D Modeling for Machine Part Design is promising, with advances in software and hardware continuing to improve the capabilities of this technology. Here are some key trends:

- Integration with Additive Manufacturing (3D Printing): As 3D printing becomes more prevalent in manufacturing, the integration of 3D modeling and additive manufacturing will allow for faster production of complex parts, reducing the time from design to production.

- AI-Powered Design Tools: Artificial intelligence is being integrated into 3D modeling software to assist with design optimization. AI can analyze millions of design iterations, helping engineers find the best solution based on specific performance criteria.

- Virtual Reality (VR) and Augmented Reality (AR): VR and AR technologies are enhancing the way engineers interact with 3D models, allowing them to experience parts in a virtual space. This immersive experience will further improve design precision and collaboration.

Conclusion:

The Indispensable Role of 3D Modeling in Machine Part Design

3D Modeling for Machine Part Design has become an indispensable tool in machine part design, offering unparalleled precision, flexibility, and efficiency. Whether used in automotive, aerospace, or medical device manufacturing, 3D modeling streamlines the design process, improves collaboration, and reduces costs. As technology continues to evolve, 3D modeling will play an even more critical role in designing and optimizing machine parts, driving innovation and enabling companies to remain competitive in an ever-changing market.

FAQs

1. What is 3D modeling for machine part design?

3D modeling for machine part design is the process of creating three-dimensional digital representations of machine components using specialized software. It allows for accurate visualization, analysis, and optimization of parts before physical production.

2. How does 3D modeling improve the design process?

3D modeling enhances the design process by providing a detailed visualization of parts, enabling real-time adjustments, running simulations, and reducing the need for physical prototypes. It improves precision, saves time, and lowers costs.

3. What software is commonly used for 3D modeling in machine design?

Common 3D modeling software includes SolidWorks, AutoCAD, Siemens NX, PTC Creo, and CATIA. These tools offer advanced features for designing, simulating, and testing machine parts.

4. How do simulations work in 3D modeling?

Simulations allow engineers to test the machine part in a virtual environment. They can assess how the part will perform under different conditions, such as stress or heat, and make necessary adjustments before moving to production.

5. Can 3D modeling reduce manufacturing errors?

Yes, by providing precise dimensions and running virtual simulations, 3D modeling helps identify potential issues before production, reducing the likelihood of errors and ensuring that parts meet design specifications.

6. What industries benefit from 3D modeling in machine part design?

Industries that benefit from 3D modeling include automotive, aerospace, consumer products, medical devices, and industrial machinery, where precision and efficiency are critical to the design and manufacturing process.