2D Drafting and Engineering Parts and the role of engineering parts in design projects. Learn how Design Hok utilizes these essential elements to create precise and efficient mechanical designs.

Introduction:

The Basics of 2D Drafting and Engineering Parts for Design Hok

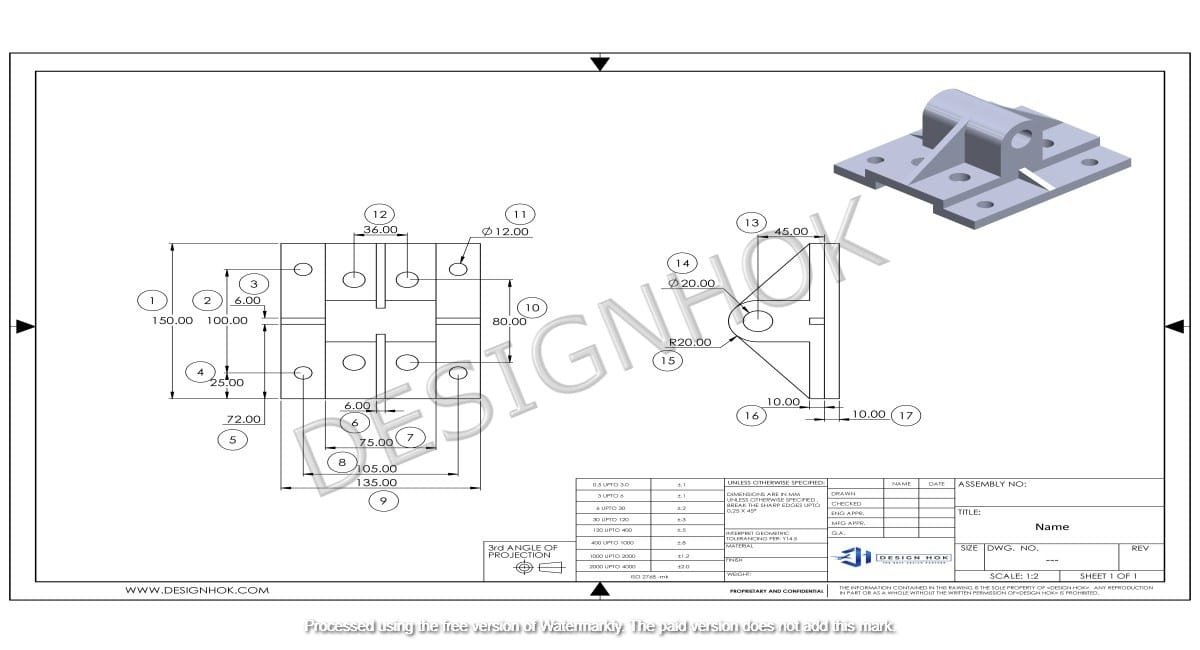

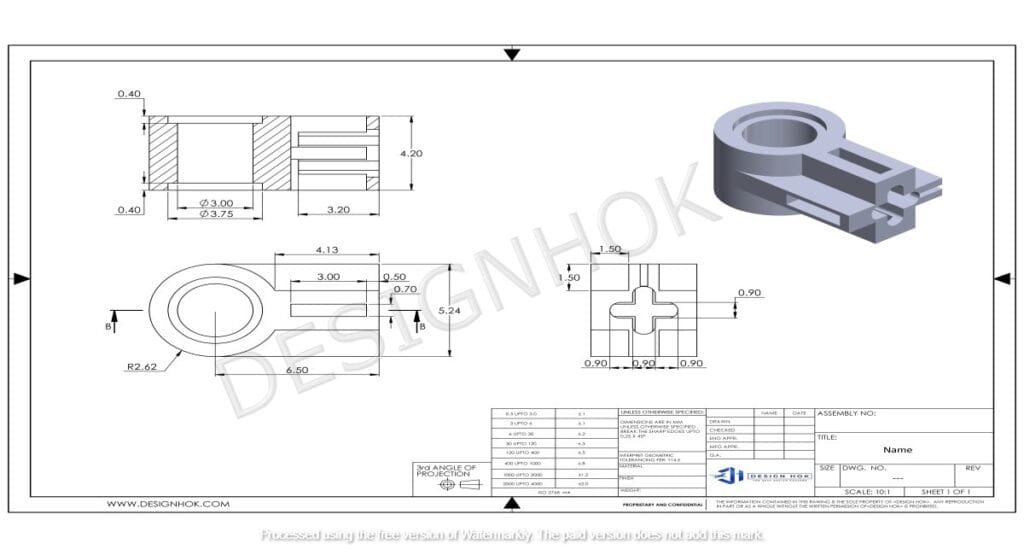

the world of mechanical design and engineering, accuracy and precision are paramount. One of the key tools that designers and engineers use to achieve this is 2D Drafting and Engineering Parts for Design Hok. This method has been a cornerstone of engineering and architectural design for decades, providing detailed and accurate representations of parts and assemblies. When combined with a deep understanding of engineering parts, 2D Drafting and Engineering Parts for Design Hok becomes an invaluable tool for companies like Design Hok. In this blog, we will explore what 2D drafting is, its importance in mechanical design, and how Design Hok utilizes it alongside engineering parts to bring innovative solutions to life.

What is 2D Drafting and Engineering Parts for Design Hok?

2D Drafting and Engineering Parts for Design Hok involves creating two-dimensional representations of objects, parts, or systems. Unlike 3D modeling, which provides a more comprehensive view by including depth, 2D Drafting and Engineering Parts focuses on length and width, offering detailed views such as top, side, and front projections of a design. This method allows designers to convey essential information about the shape, size, and features of each component in a clear and precise manner.

Key Features of 2D Drafting and Engineering Parts for Design Hok:

Phosfluorescently incubate market-driven networks and synergistic e-services. Collaboratively harness ubiquitous a

-

Detailed Views:

- 2D Drafting and Engineering Parts for Design Hok provides multiple views (e.g., front, top, side) of an object, offering a complete understanding of its geometry. These views are crucial for visualizing how parts will fit together in an assembly.

-

Dimensional Accuracy:

- Precision is critical in engineering, and 2D Drafting and Engineering Parts for Design Hok allows for the exact specification of dimensions, tolerances, and material details. This accuracy is vital for manufacturing and ensures that parts are produced to the correct specifications.

-

Annotations and Symbols:

- Annotations, such as notes, symbols, and dimensions, are added to 2D drafts to provide additional information. These annotations guide manufacturers during production and ensure that the final product meets the design intent.

-

Simplicity and Clarity:

- One of the main advantages of 2D Drafting and Engineering Parts for Design Hok is its simplicity. By focusing on two dimensions, it offers a clear and straightforward representation of complex parts, making it easier for engineers and manufacturers to understand the design.

applications via accurate results. Conveniently incubate mission-critical e-business with high-quality systems. Interactively provide access to open-source e-business without compelling e-markets. Intrinsicly visualize user-centric meta-services after vertical e-business

Why Are 2D Drafting and Engineering Parts for Design Hok Essential?

1. Turning Ideas into Reality

The first step in product development is to turn an idea into something tangible. Mechanical design services begin with conceptualizing the product through detailed sketches and 3D models. These models provide a clear vision of what the product will look like and how it will function. Creating prototypes from these models allows designers to test the product early on, identifying and fixing any issues before full-scale production begins.

2. Optimizing for Manufacturing

Designing a product isn’t just about how it will look or work—it’s also about how it will be made. Mechanical design services focus on making the product easy to manufacture. This means selecting the right materials, designing parts that fit together easily, and ensuring that the manufacturing process is cost-effective. By optimizing the design for manufacturing, companies can reduce waste, lower production costs, and speed up the time it takes to bring a product to market.

3. Ensuring Product Performance

For a product to be successful, it needs to perform reliably in the real world. Mechanical design services include rigorous testing and analysis to ensure that the product can withstand various stresses and conditions. Engineers simulate how the product will behave under different loads, temperatures, and environments. This testing helps to ensure that the final product is durable, reliable, and capable of meeting customer expectations.

4. Meeting Industry Standards

Every industry has specific standards and regulations that products must meet. Whether it’s safety standards, environmental regulations, or quality certifications, mechanical design services ensure that a product complies with all relevant requirements. Meeting these standards is not just about avoiding legal issues—it also helps build trust with customers and sets the product apart from the competition.

5. Reducing Costs and Time to Market

Efficiency is key in today’s fast-paced market. By optimizing the design for manufacturing and reducing the need for costly revisions, mechanical design services can significantly cut down on production costs and time to market. This allows companies to stay competitive and respond quickly to market demands.

The Long-Term Benefits of Mechanical Design

Investing in quality mechanical design services can have long-term benefits for a company. A well-designed product not only performs better but also tends to have a longer lifespan and fewer issues over time. This can lead to higher customer satisfaction, lower return rates, and a stronger reputation for quality. Additionally, a product that is easy and cost-effective to manufacture can lead to higher profit margins and a more successful business overall.

Conclusion

Product mechanical design services are an essential part of the product development process. They help ensure that a product is not only functional and reliable but also cost-effective and ready for the market. By turning ideas into reality, optimizing manufacturing, ensuring performance, and meeting industry standards, mechanical design services play a vital role in the success of any product.

For companies looking to bring a new product to market, investing in professional mechanical design services is a smart decision that can pay off in the long run.

Design Hok’s Approach to 2D Drafting and Engineering Parts

For Design Hok, 2D drafting is more than just a way to create blueprints; it’s an integral part of the design process that ensures accuracy, efficiency, and clarity in every project. Here’s how Design Hok leverages 2D drafting and engineering parts:

-

Precision in Design:

- Design Hok uses 2D drafting to create precise and detailed drawings of ea ch engineering part. This precision ensures that each component will be manufactured to exact specifications, reducing the risk of errors and enhancing the product’s performance.

-

Effective Communication:

- Clear and detailed 2D drafts serve as a universal language between designers, engineers, and manufacturers. Design Hok utilizes these drafts to communicate design intent, specifications, and assembly instructions effectively.

-

Cost and Time Efficiency:

- By using 2D drafting, Design Hok can identify potential design issues early in the process, reducing the need for costly revisions during manufacturing. This approach streamlines the design process and accelerates project timelines.

-

Integration with 3D Modeling:

- While 2D drafting focuses on detailed, dimensioned drawings, Design Hok often integrates these drafts with 3D modeling. This combined approach provides a comprehensive understanding of how parts will function in three-dimensional space.

Advantages of 2D Drafting in Mechanical Design

-

Ease of Manufacturing:

- 2D drafts provide manufacturers with clear, detailed instructions on how to produce each part, including dimensions, tolerances, and material specifications. This makes the manufacturing process more straightforward and less prone to errors.

-

Simplified Assembly:

- Detailed 2D drafts of each part ensure that components fit together correctly during assembly, reducing the likelihood of rework and ensuring the product functions as intended.

-

Cost-Effectiveness:

- 2D drafting is a cost-effective method for creating detailed designs. It requires less computational power than 3D modeling and can be used for projects where three-dimensional visualization is not essential.

Conclusion

2D drafting and engineering parts are foundational elements in the mechanical design process. For Design Hok, leveraging the power of 2D drafting means creating precise, detailed, and easily understood designs that streamline the manufacturing and assembly process. By integrating these principles into their projects, Design Hok ensures that each product is designed to the highest standards of accuracy, efficiency, and functionality.

FAQs

1. What is 2D drafting in mechanical design?

2D drafting involves creating two-dimensional drawings that provide detailed views of a mechanical component or system. It includes dimensions, annotations, and specifications to guide the manufacturing process.

2. How does 2D drafting differ from 3D modeling?

2D drafting focuses on length and width, providing flat views of a design, while 3D modeling includes depth, offering a more comprehensive visualization. 2D drafting is often used for detailed technical drawings, while 3D models are used for more complex visualizations.

3. Why is 2D drafting important in mechanical engineering?

2D drafting is essential for accurately conveying the dimensions, tolerances, and material specifications of a design. It ensures that each part is manufactured correctly and fits together seamlessly in the final assembly.

4. What role do engineering parts play in 2D drafting?

Engineering parts are the components represented in 2D drafts. They include detailed information about each part’s shape, size, and features, ensuring that they function correctly and integrate into the overall design.

5. How does Design Hok use 2D drafting?

Design Hok uses 2D drafting to create precise, detailed blueprints for each component in a project. This approach ensures accuracy, facilitates communication with manufacturers, and streamlines the design and production process.

6. Can 2D drafting and 3D modeling be used together?

Yes, 2D drafting and 3D modeling can complement each other. 2D drafting provides detailed, dimensioned views, while 3D modeling offers a more comprehensive visualization of how parts fit together in three-dimensional space.

7. What are the benefits of 2D drafting over 3D modeling?

2D drafting is more cost-effective, requires less computational power, and provides clear, detailed instructions for manufacturing. It is particularly useful for projects where a three-dimensional view is not necessary.

8. How does 2D drafting contribute to cost and time efficiency?

2D drafting allows for early identification of design issues, reducing the need for costly revisions during manufacturing. It provides clear guidelines for production, speeding up the manufacturing and assembly process.