Milling that Brings Your Ideas to Life

In the modern world of design and manufacturing, if you have the right technical support, then it makes a difference. The professional 2D and 3D milling support helps all types of businesses, from small startups to large industries, bringing ideas to the real world. Expert milling services provide the right combination of skilled designers, if you need 2D or 3D prototypes with the help of advanced tools. In this article, you’ll learn about 2D and 3D milling and how they work.

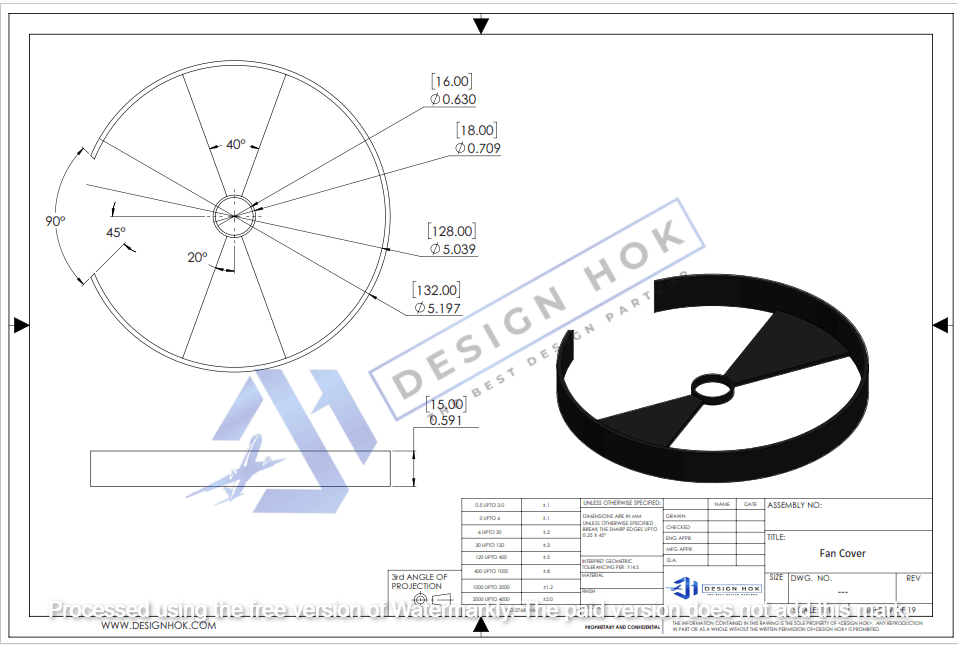

What Is 2D and 3D Milling Support?

Engineers and manufacturers convert digital designs into the real world with the help of milling support.

Basics Milling

The most basic milling is the 2D milling, in which material is removed from a solid block to create a shape. It operates on the X-axis and Y-axis. It is the best way to create simple and flat shapes. It also involves preparing 2D technical drawings that define cutting paths, dimensions, and tolerances. These drawings guide the CNC machine to cut parts precisely according to the design.

Advanced Geometry

In 3D milling, they use advanced geometry to add depth and height, which allows for the creation of more complex geometries and curves. This method is perfect for making prototypes, molds, dies, and mechanical parts with intricate details. They use advanced software and multi-view to produce accurate and high-quality parts in various materials, which include aluminum, steel, brass, and plastics. It is widely used in industries such as aerospace, automotive, and medical manufacturing.

Why Use Professional 2D and 3D Milling Support?

When you work in a professional environment, you learn a lot from their expertise. Here’s what makes professional milling supports

1. Professional Engineers

Every real-world project is handled by an expert who understands both mechanical design and production requirements. They make sure every design isn’t just creative but also practical for manufacturing. This thing helps us to create a balanced project.

2. End-to-End Service

In the early design stage, comprehensive milling support covers everything. This process includes managing the entire workflow under one roof, which fills all gaps between designers and machinists. This move toward smoother operations and lower chances of delays.

3. Fast Turnaround

In this, engineers use advanced digital tools, which offer quick design edits and rapid prototyping. Now, if it’s a basic 2D plate or a complex 3D part. The target is to deliver precise results quickly.

4. Flexibility

It’s used in various industries like the aircraft industry, automotive, medical, and industrial machinery. All project is customized based on their requirement and materials.

The Process: How 2D and 3D Milling Support Works

A proper workflow ensures accuracy and consistency.

Step 1:

The process begins with a discussion about the project’s needs. You can provide sketches, 2D drawings, or 3D models. If you only have an idea, the experts in this industry will help you convert it into a real-world tool if it’s helpful. This step is also called consultation

Step 2:

In design, the engineers proceed with drafting 2D or 3D models that follow CNC milling standards. Engineers ensure accuracy by following the engineering standards precisely.

Step 3:

After drafting, they move toward the next step, which is called CAM. In this process, they generate tool paths and understand machine strategies using different softwares. This stage tells us how the CNC machine will cut and shape the material.

Step 4:

After all inspections, the client receives files, including CNC, 2D blueprints, and toolpath documentation. These files are optimized for operators.

Step 5:

After file delivery, the assistance is available for revisions, prototype improvements, or machining-related guidance. Engineers ensure the entire production process runs smoothly from design to final output.

Tools and Software Used

- They use AutoCAD for 2D drafting and technical drawings.

- For 3D modeling and mechanical design, they use SolidWorks.

- For CAD and CAM workflows, they use Fusion 360.

- For advanced toolpath generation and machining simulations, they use Mastercam.

These tools ensure that these machine provides a seamless transition from design to production. The professional uses industry-leading tools to deliver precise and error-free results.

Benefits of Professional 2D and 3D Milling

If we choose professional milling supports like Design Hok, then they offer a lot of advantages that improve design and production speed.

- There are very low chances of errors because of accurate workflows through advanced softwares.

- These experts offer clear technical documentation that simplifies setup for the machinist.

- Our experts offer faster teamwork between design and production teams.

Why Professional Milling Support Matters

Professional use of 2D and 3D milling ensures that every part is designed. With the combination of our professional engineers and modern software. Our clients receive a ready-to-produce file and assistance from start to end. From small prototypes to complex industrial components, 2D and 3D milling services deliver consistent, high-quality results that meet industry standards and deadlines.

Conclusion

In this modern era, milling support makes a bridge to bridge the gap between imagination to production. It transforms ideas into real-world and functional parts with speed, accuracy, and efficiency. Now, if you’re developing a prototype or improving an existing design for major industries. Professional milling support provides precise design files to machine-ready data. With current advanced technology, experienced professionals, and a focus on quality, 2D and 3D milling continues to power innovation, helping industries create better products faster and more efficiently.